Elastic push-and-press type high-voltage fuse tube base

A technology for high-voltage fuses and sockets, which is applied to electrical components, circuits, emergency protection devices, etc., can solve problems such as the installation structure of high-voltage fuses that are not involved, avoid lateral force on the fuse tube, improve equipment operation safety, and ensure The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

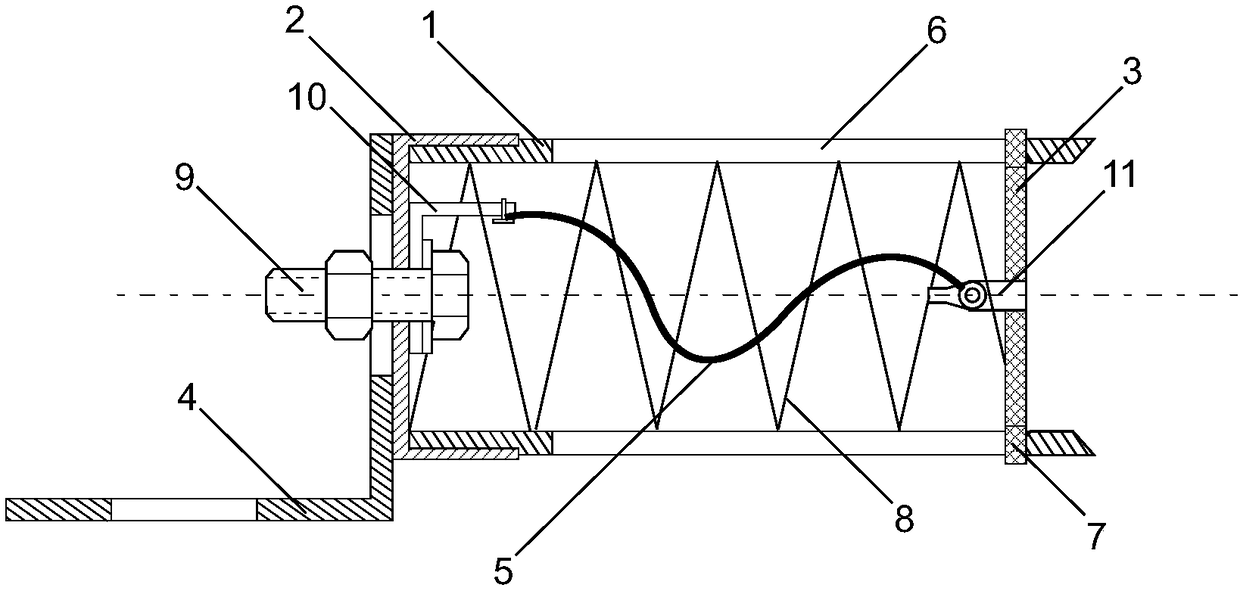

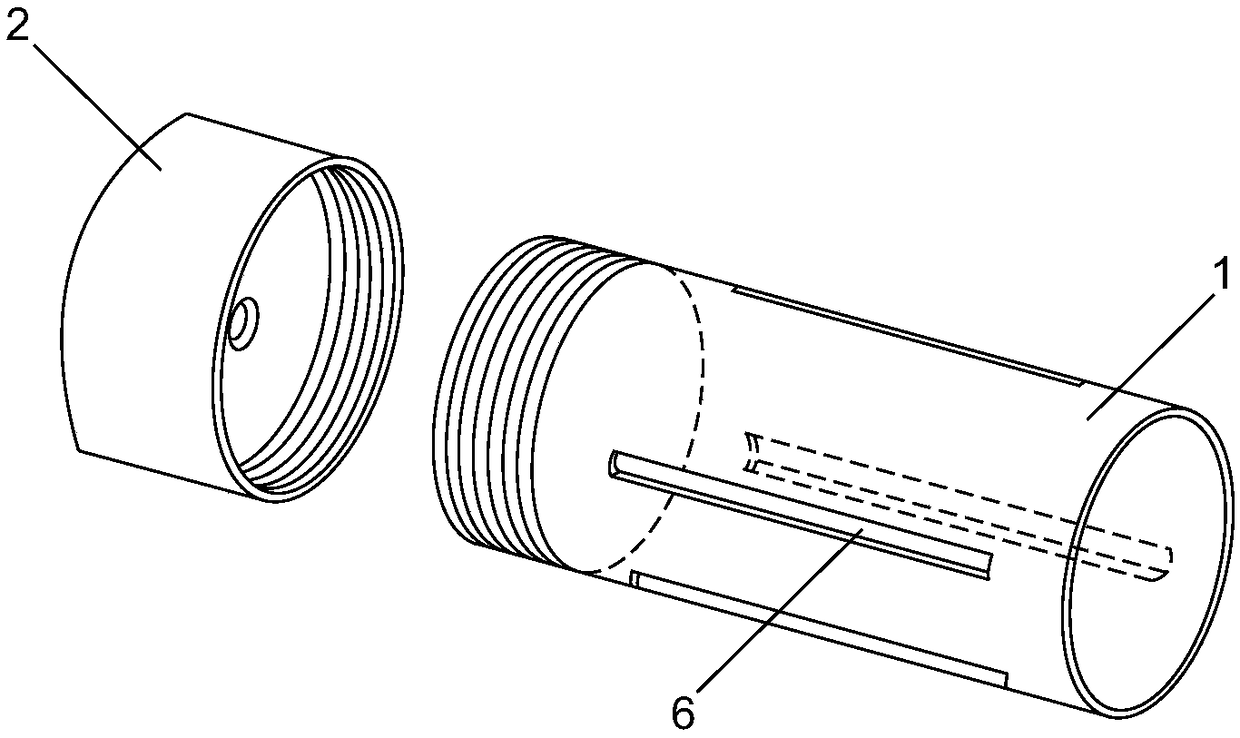

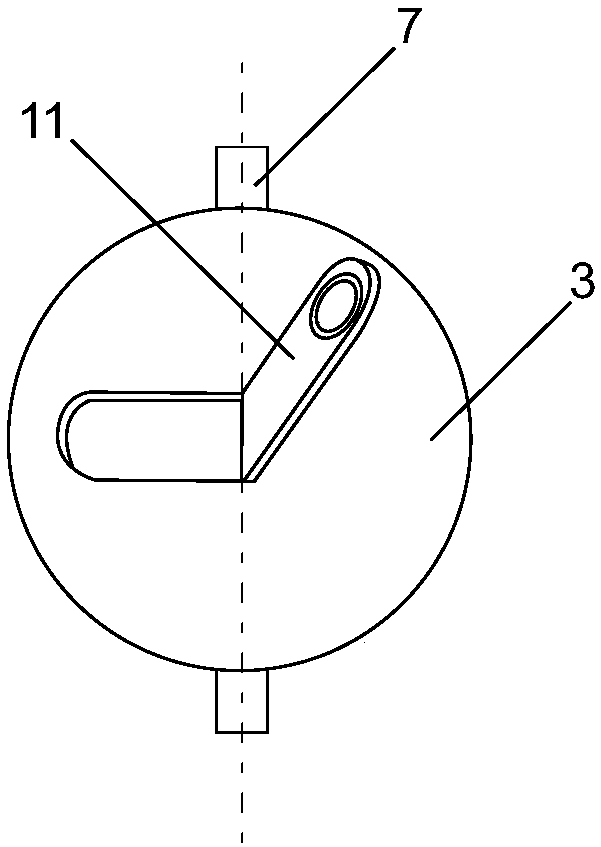

[0024] Such as figure 1 , image 3As shown, an elastic push-type high-voltage fuse socket includes a cylindrical hollow conduit 1 for installing a fuse tube, a conduit end cover 2 and a contact slide plate 3, and the conduit end cover 2 is fixed on a fixed frame 4 Above, the hollow conduit 1 is threadedly connected with the conduit end cover 2, and a top spring 8 is also provided between the contact slide plate 3 and the conduit end cover 2. Up is relatively fixed. The hollow conduit 1 is provided with two parallel slots 6 penetrating through the inner and outer walls of the hollow conduit 1, and the edge of the contacting slide plate 3 is provided with symmetrical bumps 7, and the bumps 7 are adapted to be embedded in the slots 6, and the bumps 7 are evenly distributed on the edge of the contact slide plate 3, and the two projections 7 are 180° relative to the axis of the hollow conduit 1. A detachable flexible wire pigtail 5 is connected between the contact slide plate 3 ...

Embodiment 2

[0027] Such as figure 2 As shown, there are four slots 6, which are evenly distributed on the wall of the hollow conduit 1 and arranged in a cross shape. The inner diameter of the hollow conduit 1 is 6mm larger than the outer diameter of the matching fuse tube. All the other are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com