Water heater communication failure detection method

A technology for communication faults and detection methods, applied in digital transmission systems, electrical components, transmission systems, etc., can solve problems such as inconvenience in maintenance, inability to determine fault points in time, and save maintenance time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

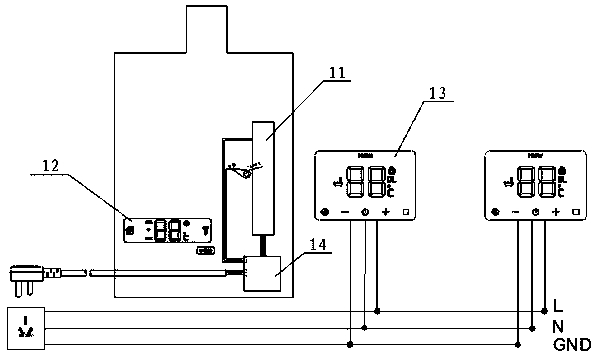

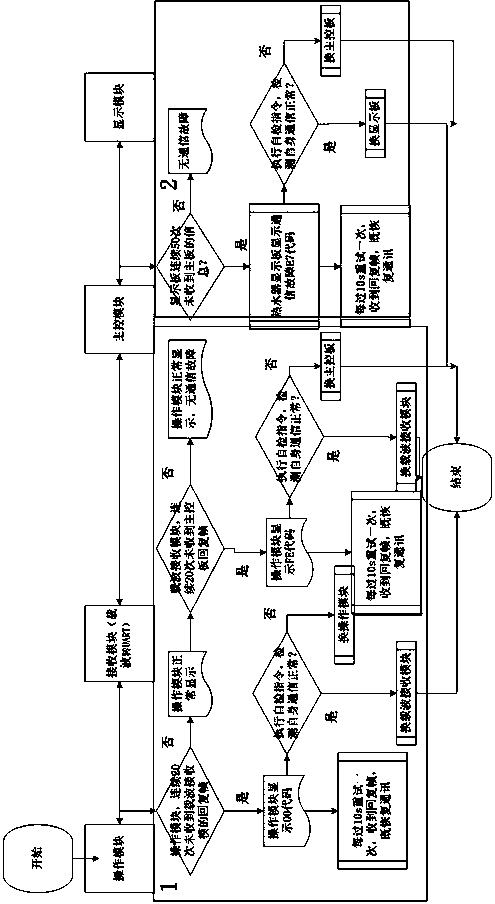

[0027] Embodiment 1. This embodiment proposes a water heater communication fault detection method. The connection structure of the gas water heater used in this embodiment is as follows: figure 1 As shown, the gas water heater at least includes a main control module 11 and one or more operation modules 13 with power carrier communication function. The operation module 13 is connected to the mains, and the main control module 11 is connected to the carrier receiving module 14 through a weak current signal line. The carrier receiving module 14 is connected to the commercial power, and the operation module 13 and the main control module 11 communicate through the power line. The carrier receiving module 14 is used to receive the signal sent by the operation module 13 in the power line, and convert it to generate a weak current signal and send it to the main control module. 11. The water heater communication fault detection method in this embodiment includes the following steps:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com