Vertical type solid-liquid separation equipment

A solid-liquid separation and equipment technology, which is applied in the field of solid-liquid separation equipment, can solve the problems of automatic unloading, difficult loading and unloading, and bulkiness, and achieve the effect of automation, simple and practical process, and rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

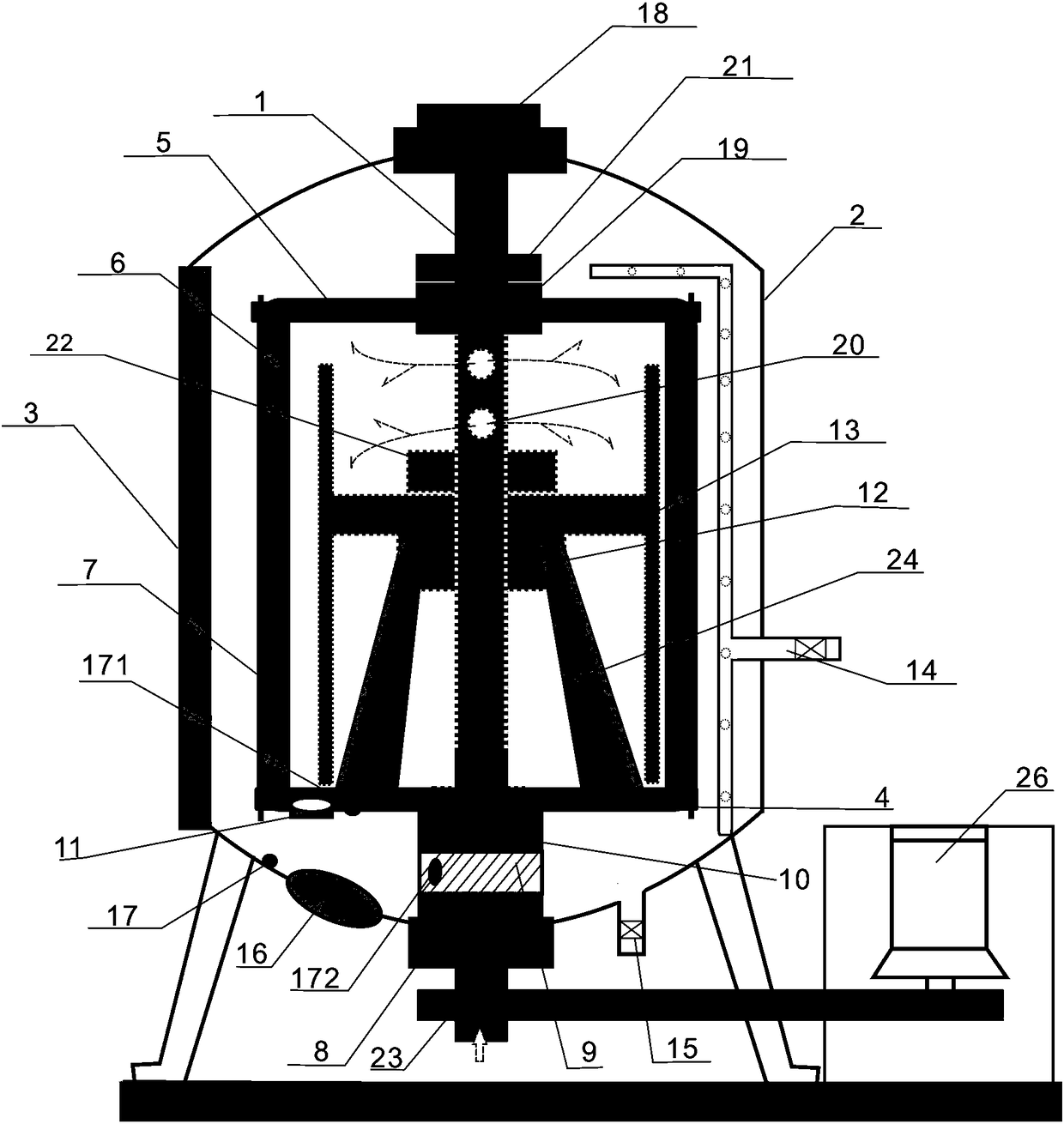

[0025] like figure 1 As shown, a vertical solid-liquid separation device of the present invention includes a filter cavity, a liquid discharge cavity, a main shaft 1, a body 2, a hatch device 3, a supporting cover device 4, an upper cover device 5, and a filter plate device 6 , column device 7, sealing device 6 8, coupling flange 9, sealing device 5 10, discharge hole cover 11, sealing device 3 12, scraping device 13, spray pipe 14, drain pipe 15, manhole device 16. Positioning device one 17, positioning device two 171, positioning device three 172, sealing device one 18, sealing device two 19, liquid outlet 20, upper conjoined flange 21, detachable flange 22, transmission wheel 23, support Plate assembly 24, motor 26, wherein:

[0026]The main shaft 1 is connected to the bottom of the body 2 through the sealing device 6 8 , the main shaft 1 is connected to the cover device 4 through the sealing device 5 10 , and the main shaft 1 is connected to the sealing device 2 19 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com