A method of manufacturing partially rounded convex steel strips

A manufacturing method and technology of steel slats, applied in the field of construction raw materials, can solve the problems of complex preparation process, weak bonding force between steel bars and concrete, etc., and achieve the effect of simple manufacturing process, good market prospect and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

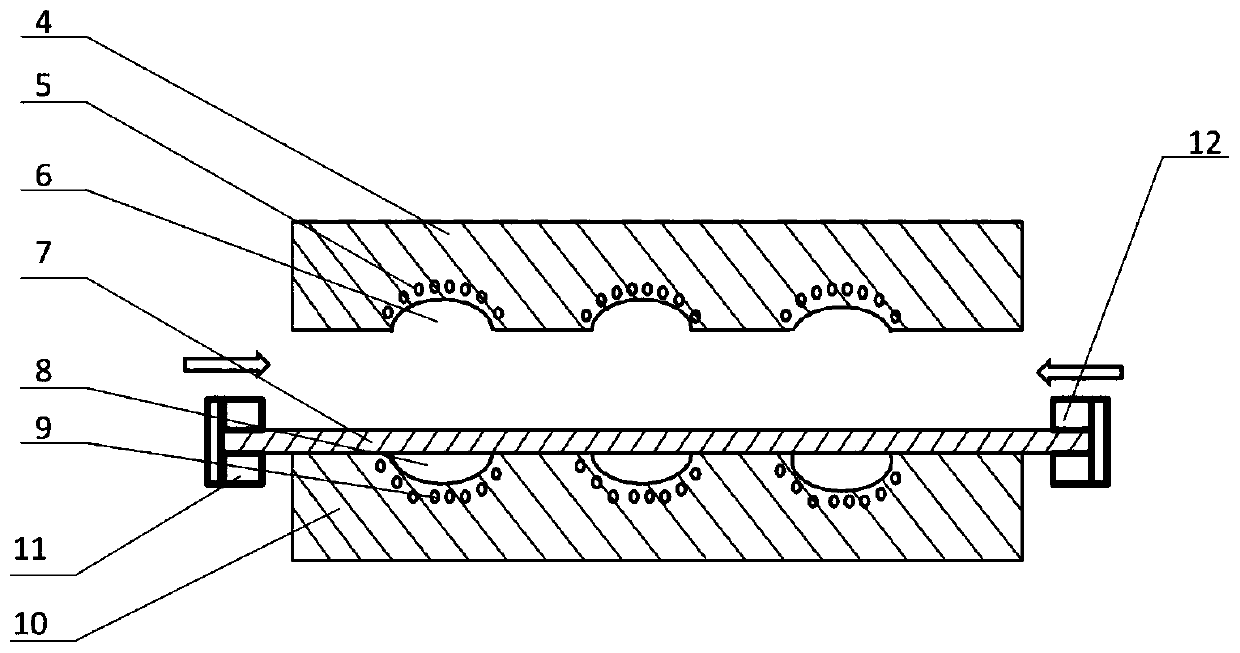

[0026] Referring to the accompanying drawings, a detailed description will be given of a method for manufacturing a partially rounded steel strip proposed by the invention in conjunction with specific embodiments.

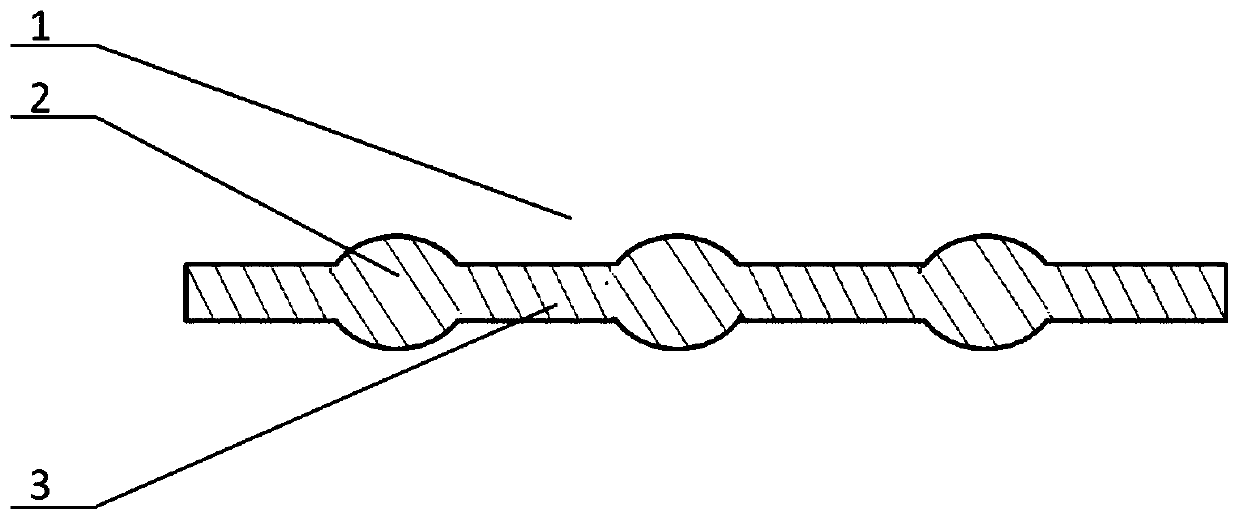

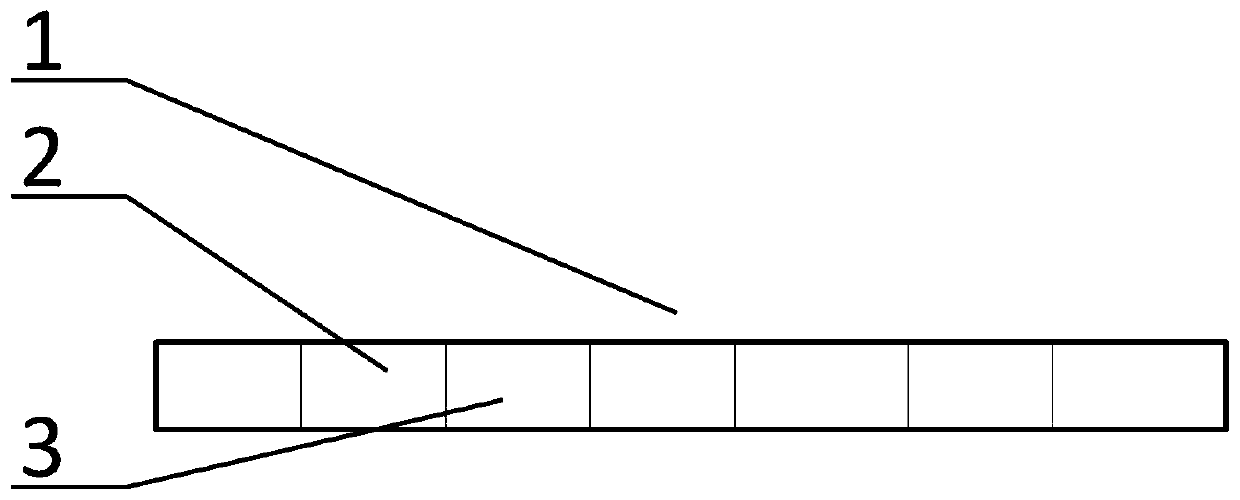

[0027] Such as Figure 1-2 As mentioned above, the partial circular convex steel strip 1 proposed by the present invention has such a structure: the partial circular convex steel strip 1 is a steel plate square strip of a certain length, and there are local circular convex 2 arranged at intervals on it, and the adjacent partial circular convex 2 A transition zone 3 is provided between them, and the transition zone 3 has undergone roughening treatment, and the transition zone 3 has adjacent grooves and convex structures to increase the bonding force between the partially circular convex steel strip 1 and the concrete.

[0028] A method for manufacturing a partially rounded steel strip provided by the technical solution of the present application comprises the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com