Material conveying mechanism and electric cooker inner container punching equipment

A conveying mechanism and material technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as unfavorable production efficiency, and achieve the effect of preventing waste accumulation and speeding up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

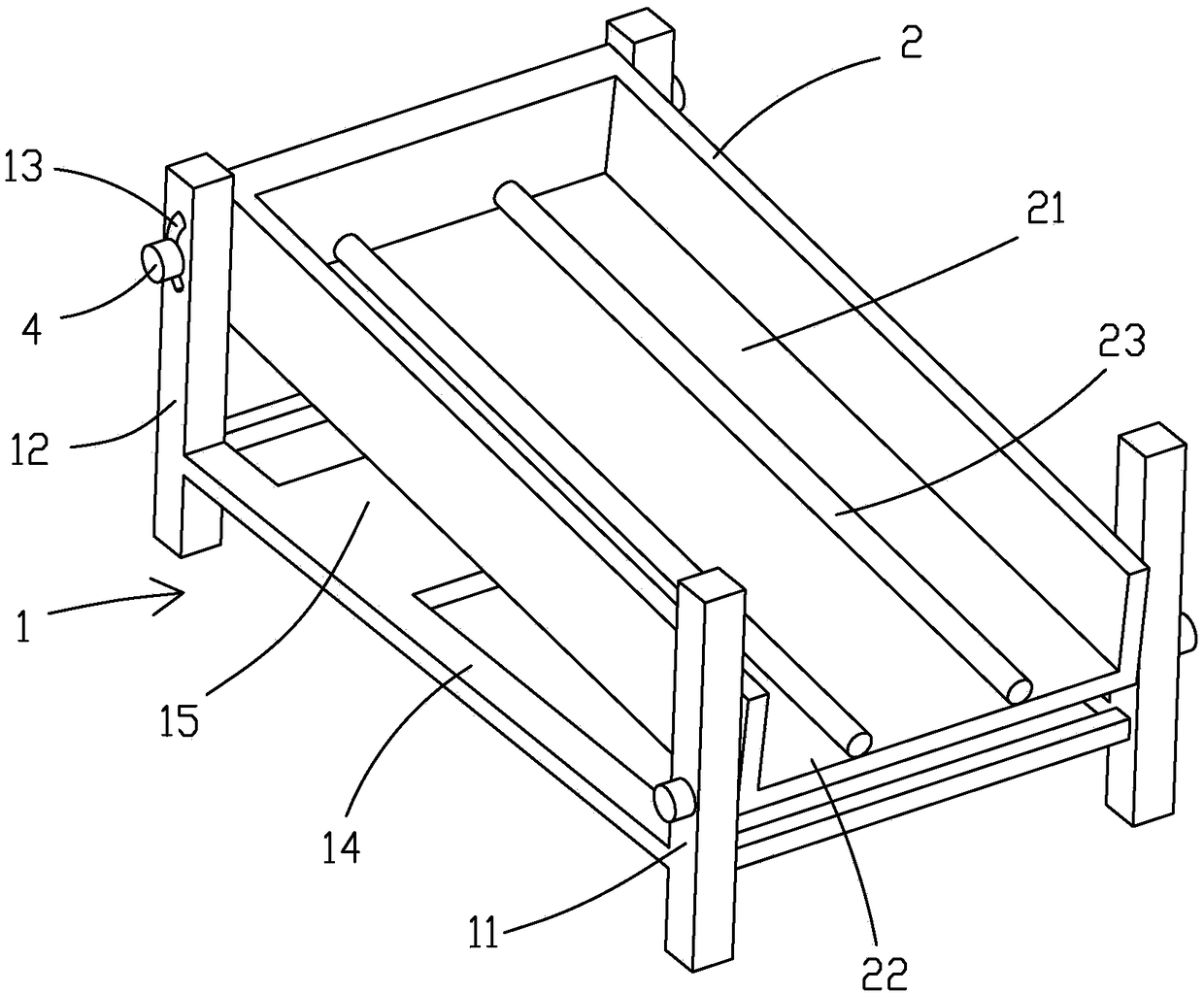

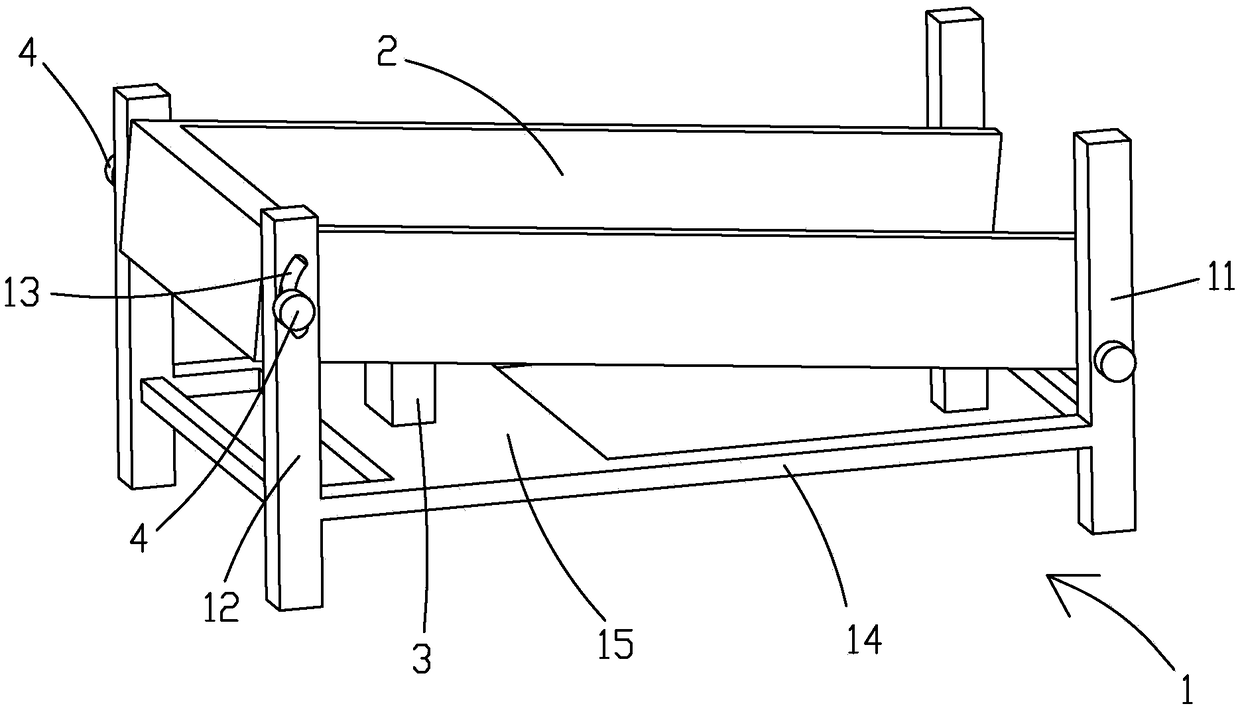

[0021] like figure 1 and figure 2 The material conveying mechanism shown includes a bracket 1 and a feeding seat 2 arranged on the bracket 1, the feeding seat 2 is provided with a feeding chute 21 arranged obliquely, and the lower end of the feeding chute 21 is at the A material outlet 22 is formed on the feeding seat 2, and the end of the feeding seat 2 away from the material outlet 22 is higher than the end of the feeding seat 2 close to the material outlet 22, and the material feeding seat 2 is close to the material outlet 22 One end is hinged on the support 1, the end of the feeding seat 2 away from the material outlet 22 is flexibly connected to the support 1 and can move up and down relative to the support 1, and the material conveying mechanism also includes a The drive device 3 on the support 1 is used to drive the end of the feeding seat 2 away from the material outlet 22 to move up and down relative to the support 1. Specifically, the drive device 3 is a vibrating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com