Solar cell lamination equipment and lamination method thereof

A technology of solar cells and solar panels, applied in lamination, lamination devices, lamination auxiliary operations, etc., can solve problems such as incomplete discharge of air bubbles, displacement of solar cell components, and impact on the quality of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

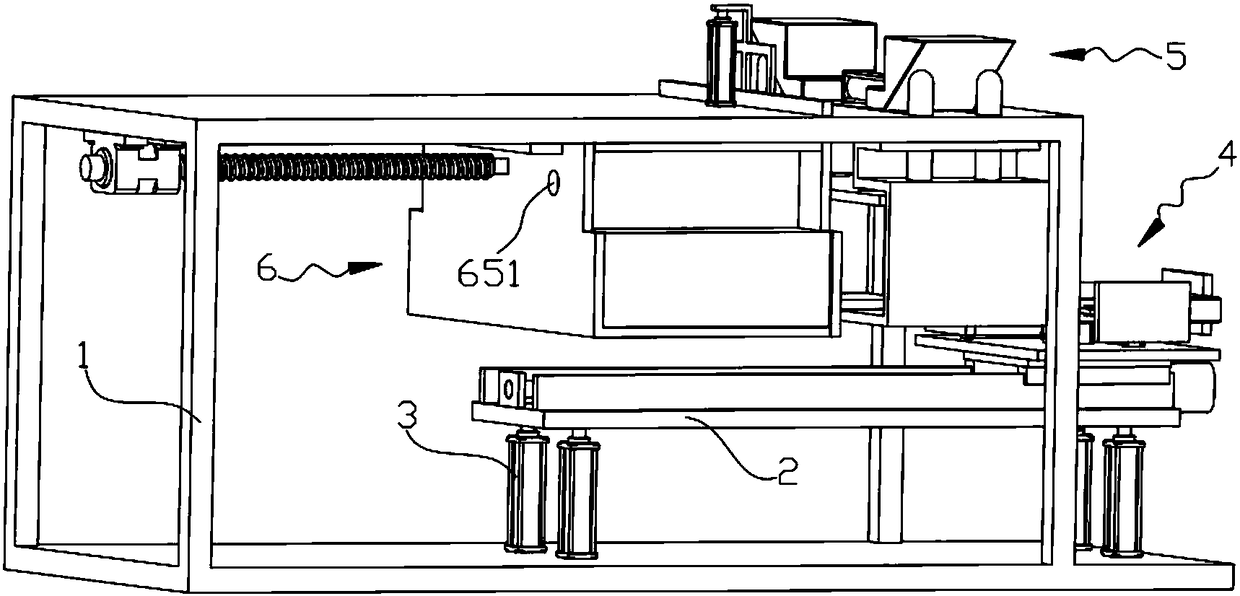

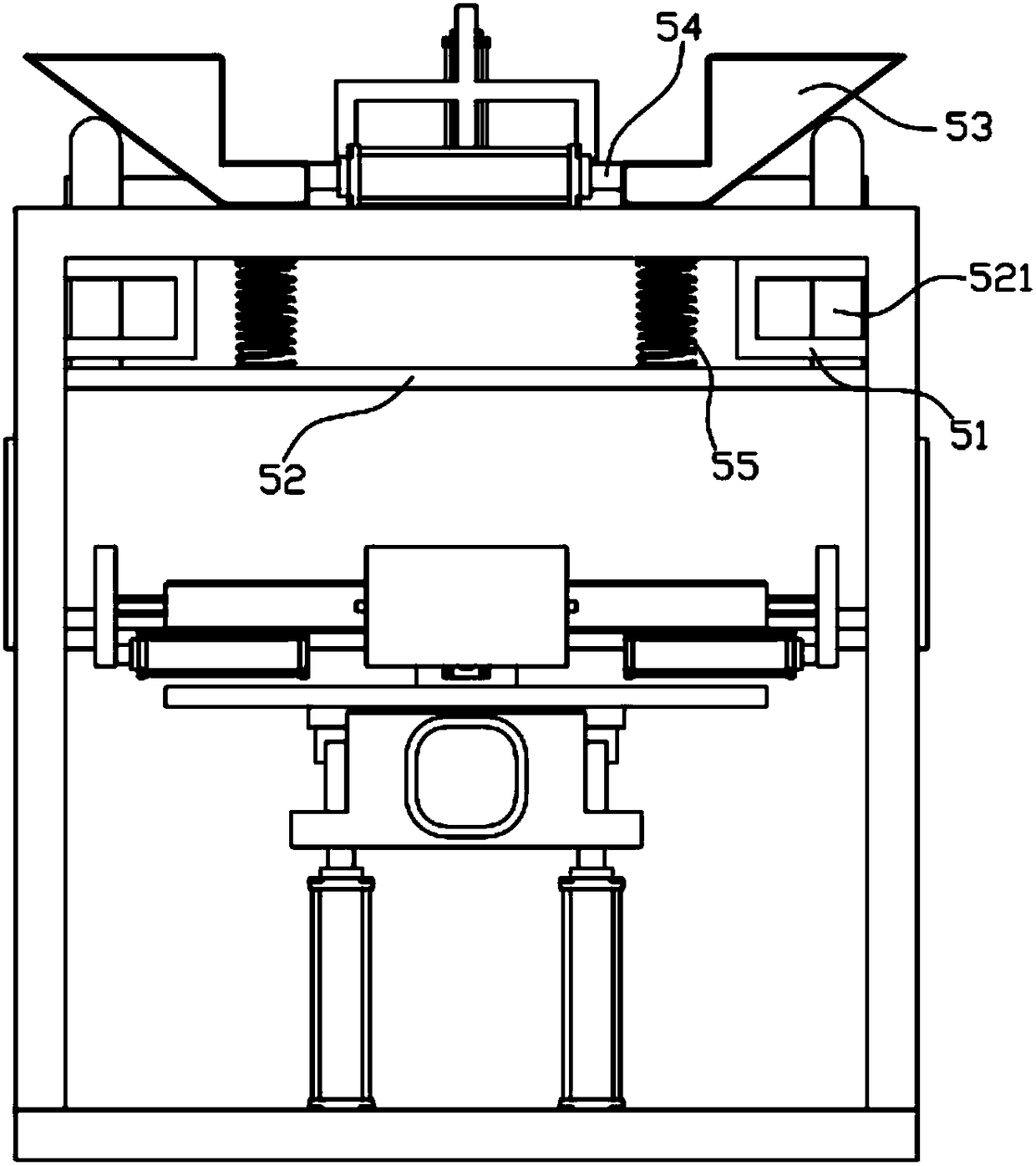

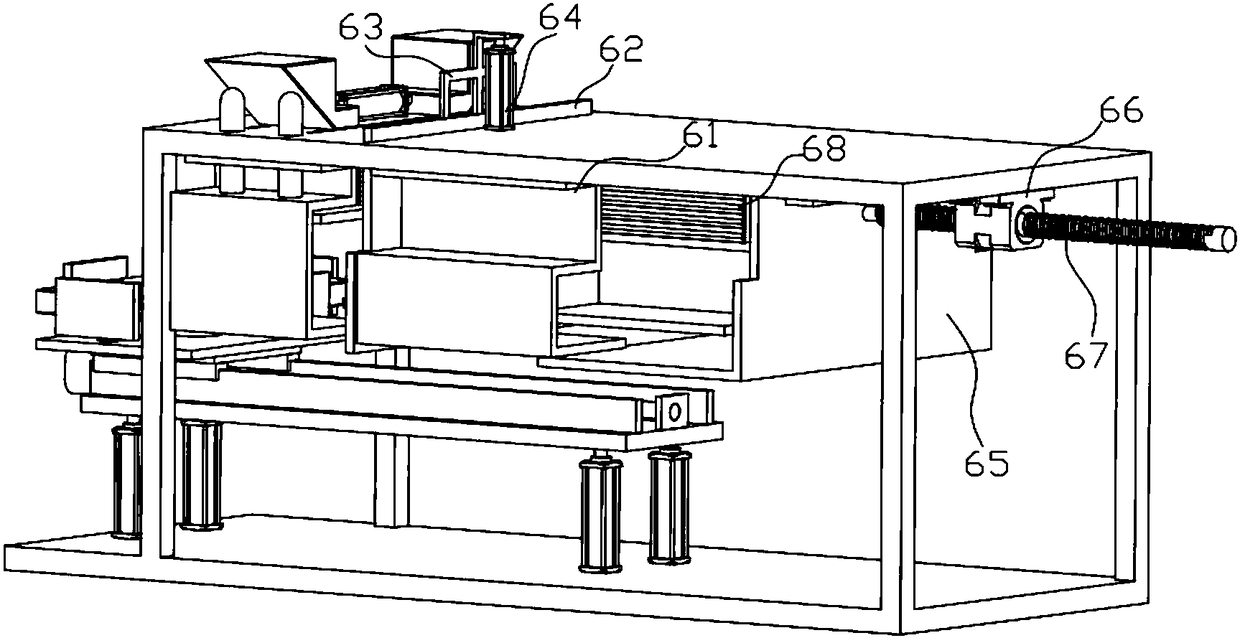

[0029] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0030] A solar cell lamination equipment, including a frame 1, a conveying platform 2, a supporting hydraulic cylinder 3, a clamping mechanism 4, a pre-pressing mechanism 5 and a laminating mechanism 6, wherein:

[0031] Four supporting hydraulic cylinders 3 are fixedly installed on the frame 1, and their power output ends are fixedly connected with the conveying platform 2, wherein the four supporting hydraulic cylinders 3 are located at the four corners of the conveying platform 2, and then the conveying platform 2 passes through four The support hydraulic cylinder 3 is movably installed on the frame 1, wherein the conveying platform 2 is located below the pre-pressing mechanism 5 and the laminating mechanism 6.

[0032] Clamping mechanism 4, which includes a lower support plate 41, an upper support plate 42, a telescopic plate 43 and a hydraulic cylinder I44, the upper support plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com