Loss-prevention building material transport case

A technology for building materials and transport boxes, applied in the directions of transportation and packaging, vehicles for freight, superstructures of trucks, etc., can solve problems such as road bumps, economic losses, safety accidents, etc. missing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

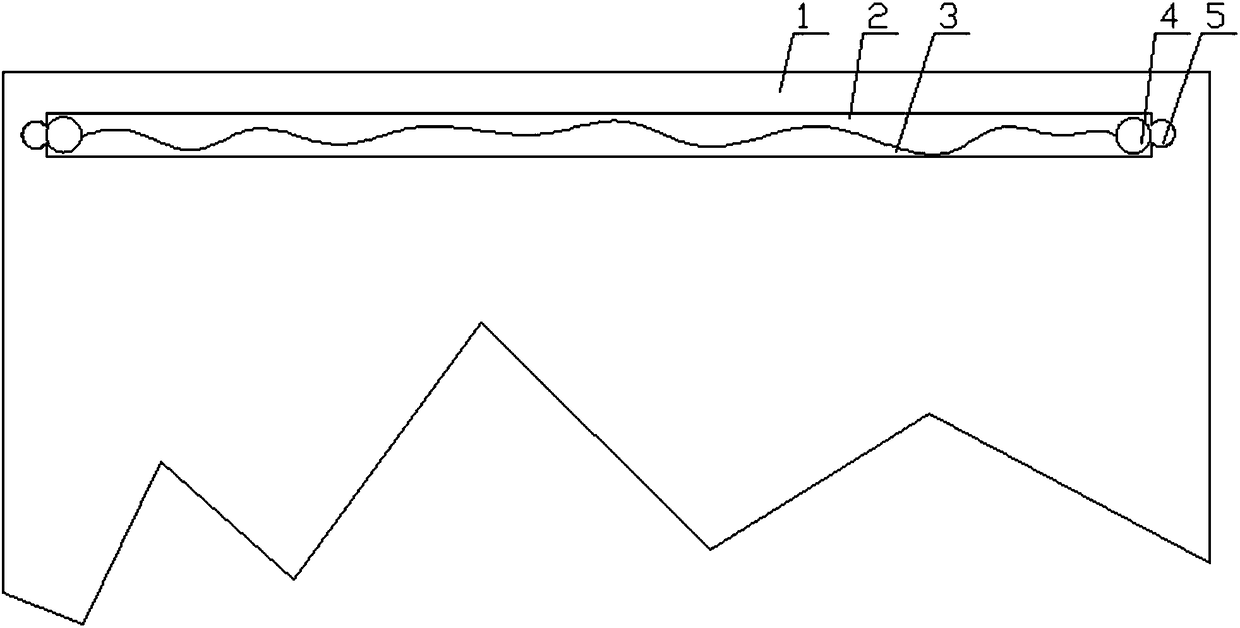

[0018] Such as figure 1 As shown, the leakage-proof construction material transport box includes two compartment side panels 1 and also includes a sliding rod 4. The two compartment side panels 1 are provided with a horizontal sliding cavity 2, and at least two sliding rods 4 are provided. The two ends of 4 respectively pass through the sliding cavities 2 of the two compartment side panels 1, a tarpaulin 3 is arranged between the two sliding rods 4, two cylindrical through holes are arranged at both ends of the tarpaulin 3, and the cylindrical through holes are used for Wrapping the sliding rod 4; a caliper hole 5 is provided at both ends of the sliding cavity 2, the caliper hole 5 communicates with the sliding cavity 2, and the edge of the caliper hole 5 communicating with the sliding cavity 2 is provided with a soft material.

[0019] The length of the tarpaulin 3 is equal to and greater than the length of the sliding cavity 2 .

[0020] Slide bar 4 adopts hollow steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com