A mining hydraulic rock splitter

A rock-cracking and hydraulic technology, applied in the direction of discharge machinery, earth square drilling and mining, etc., can solve the problems of environmental workers' damage, ore size splitting, ore splitting inconvenient, etc., and achieve the effect of convenient connection and insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

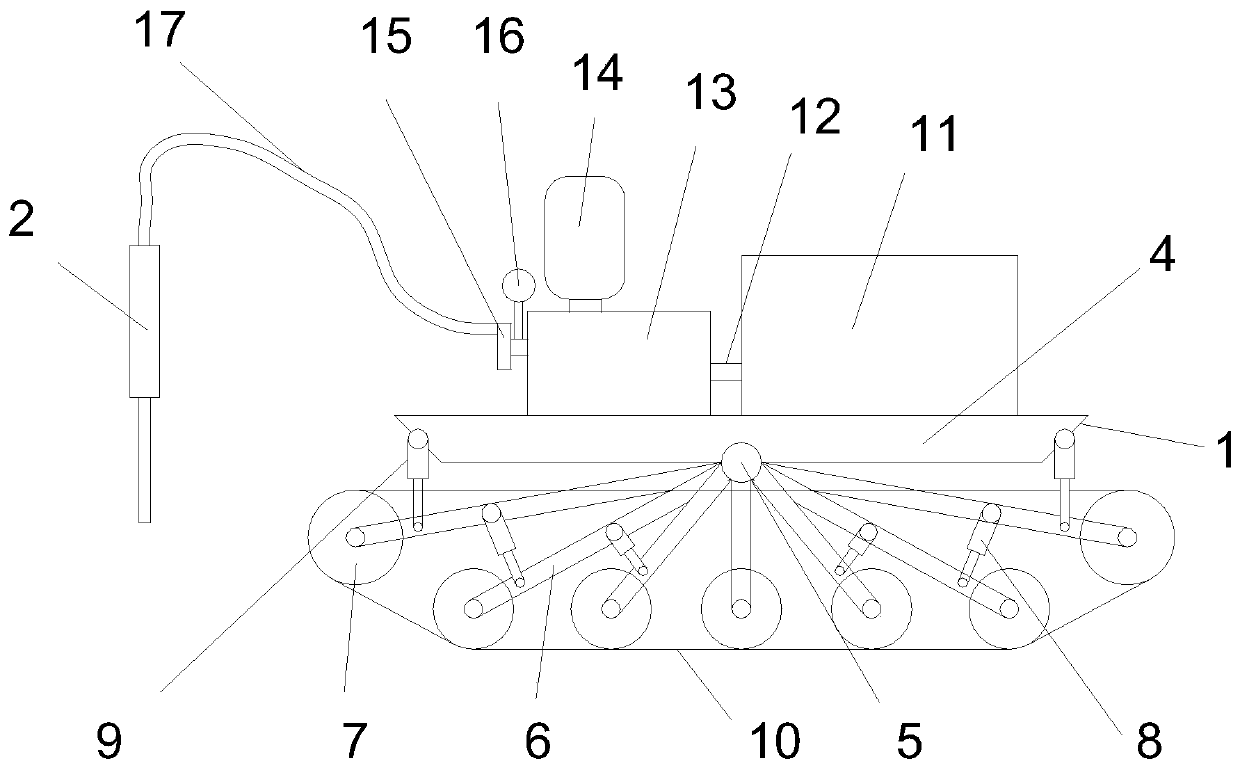

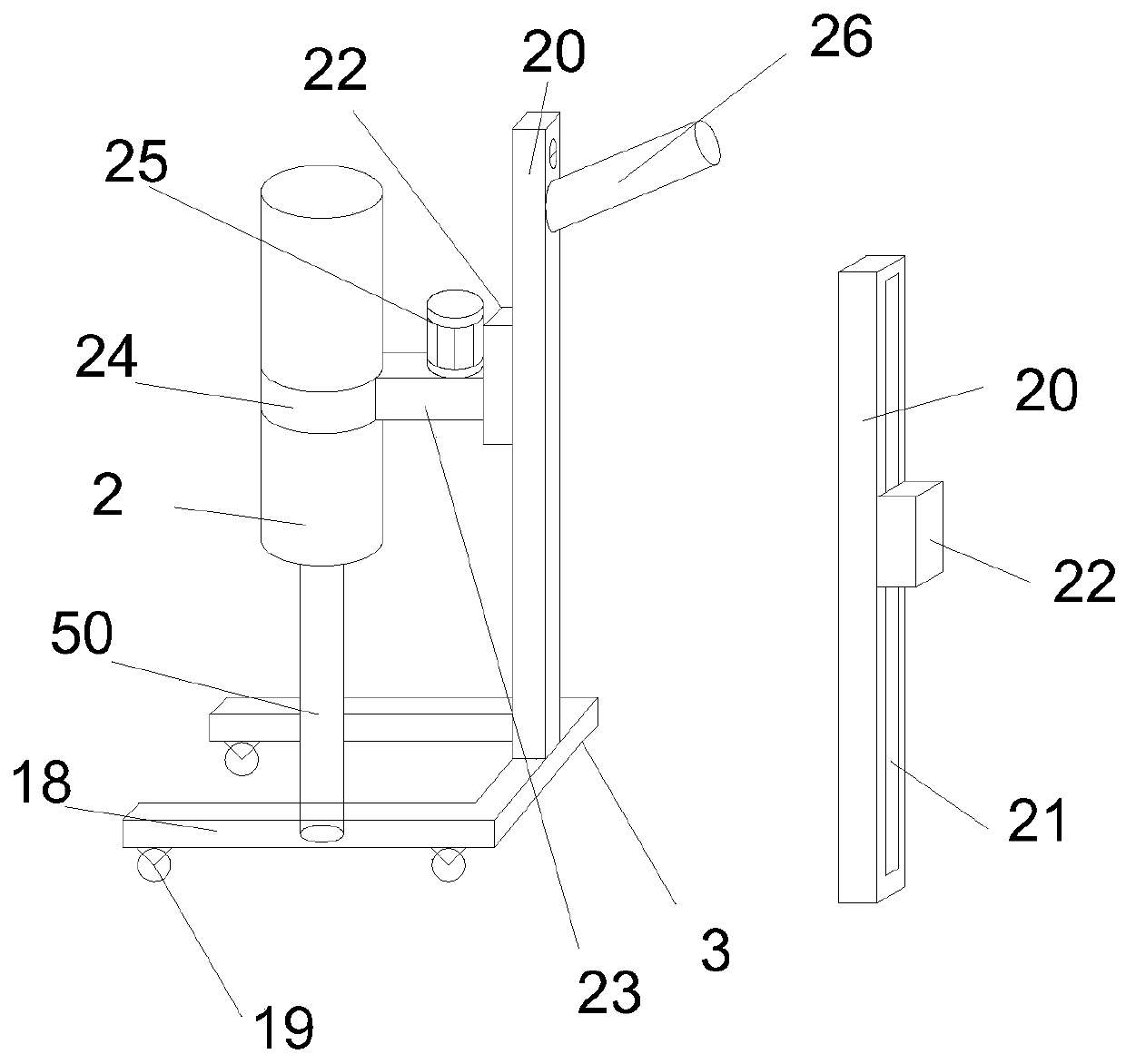

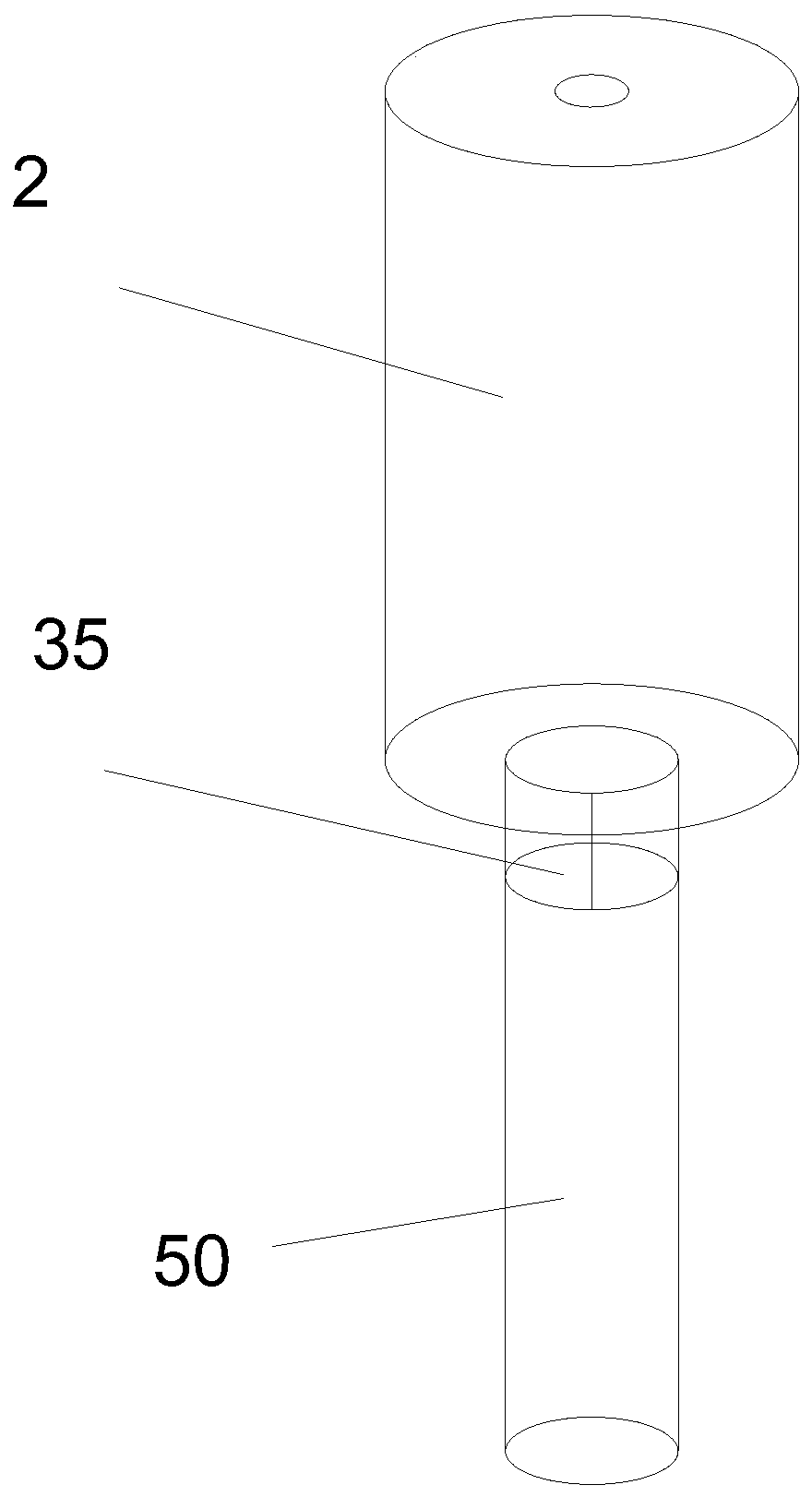

[0021] Embodiment 1: A hydraulic rock cracking machine for mining, comprising a moving device 1, a rock cracker 2 and a rock cracking support device 3. The moving device 1 is provided with a chassis 4, and the bottom of the chassis 4 is provided with a connecting shaft 5. A connecting wheel rod 6 is connected to the connecting shaft 5, one end of the connecting wheel rod 6 is provided with a crawler wheel 7, a hydraulic rod 8 is provided between the connecting wheel rods 6, and both sides of the chassis 4 are provided Damping hydraulic rod 9, said damping hydraulic rod 9 is connected with connecting wheel rods 6 on both sides. The crawler wheel 7 is provided with crawlers 10, and the connecting wheel rod 6 can be damped by rotating the connecting shaft 5, and the connecting wheel rod 6 The hydraulic rod 8 in between can better dampen the mobile device and facilitate the movement of the device.

[0022] The upper side of the chassis 4 is provided with a hydraulic oil tank 11, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com