Modular capillary tube multi-channel gas-liquid pipeline quick connecting device

A fast connection and capillary technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of high labor intensity, low connection efficiency, single selection, etc., to achieve accurate alignment, improve efficiency, and reduce labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

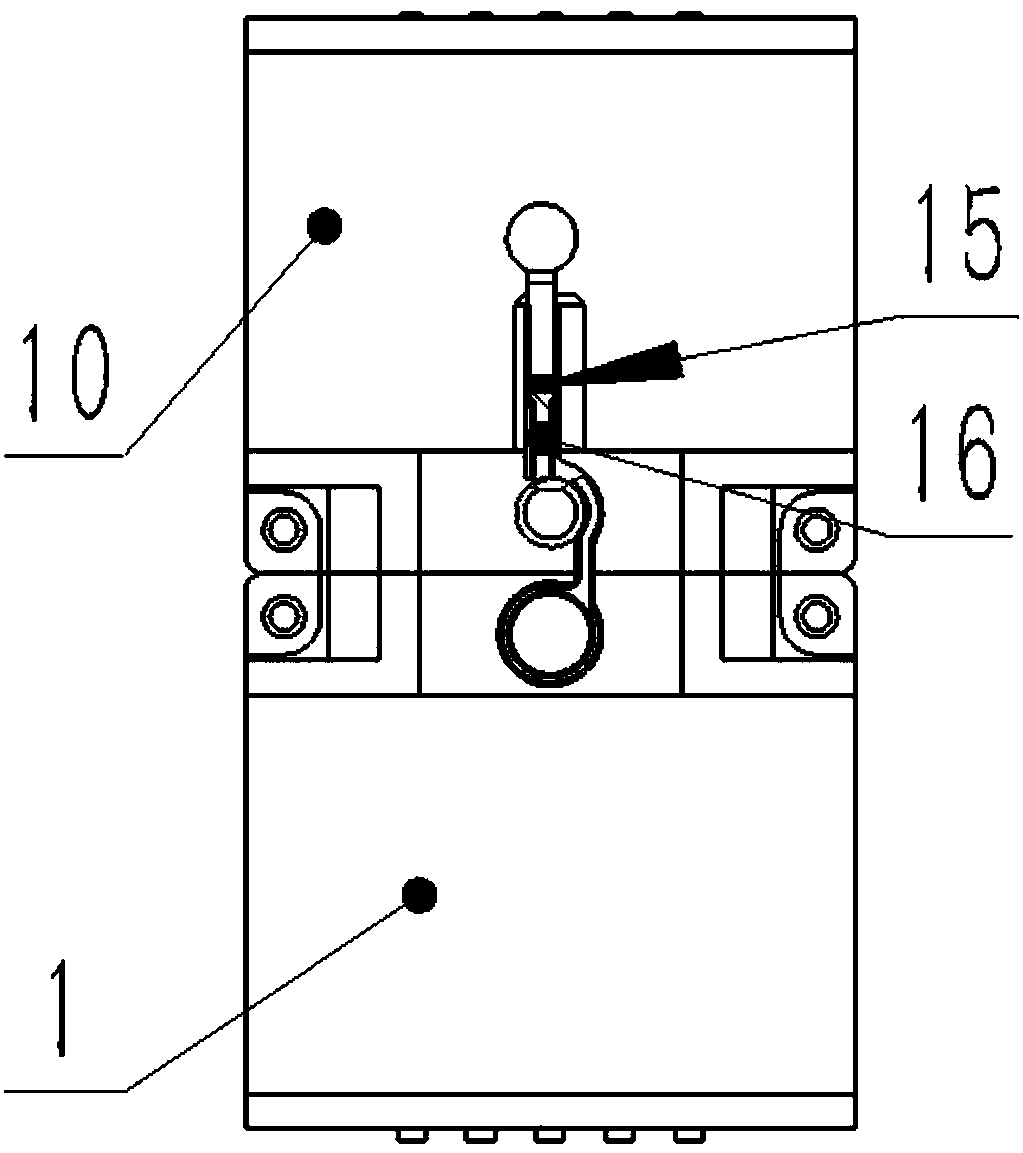

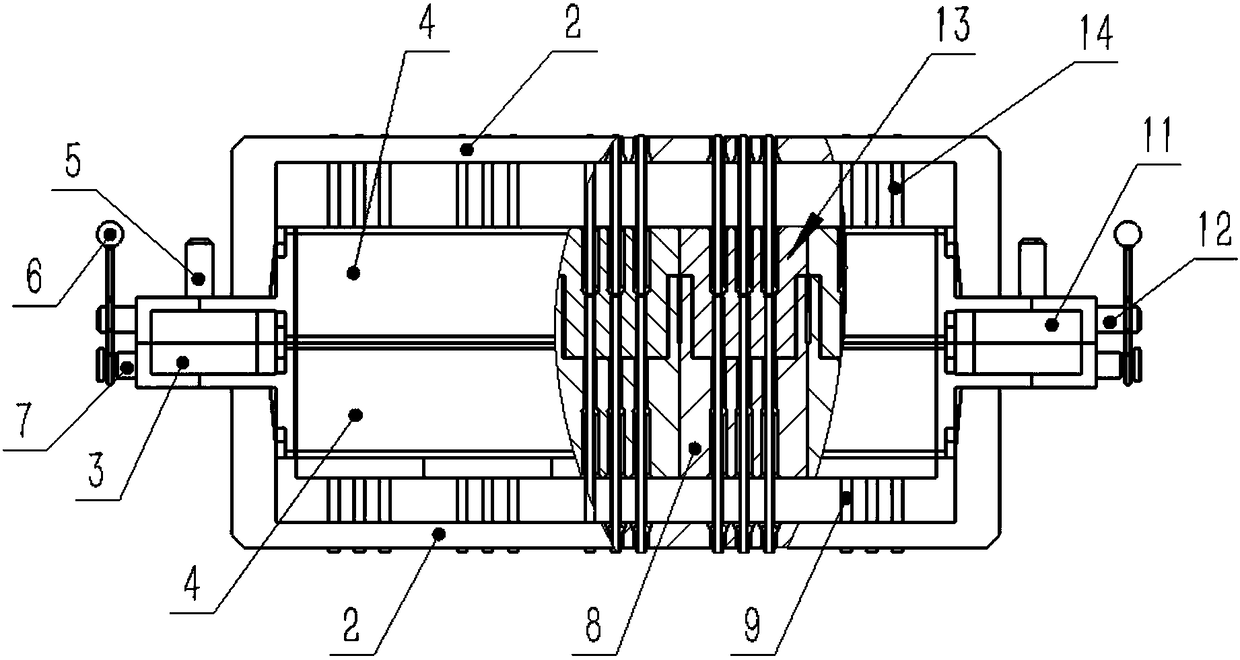

[0027] Such as figure 1 with figure 2 As shown, this embodiment provides a modular capillary multi-channel gas-liquid pipeline quick connection device, which includes two parts: the male end 1 of the capillary multi-channel module and the female end 10 of the capillary multi-channel module.

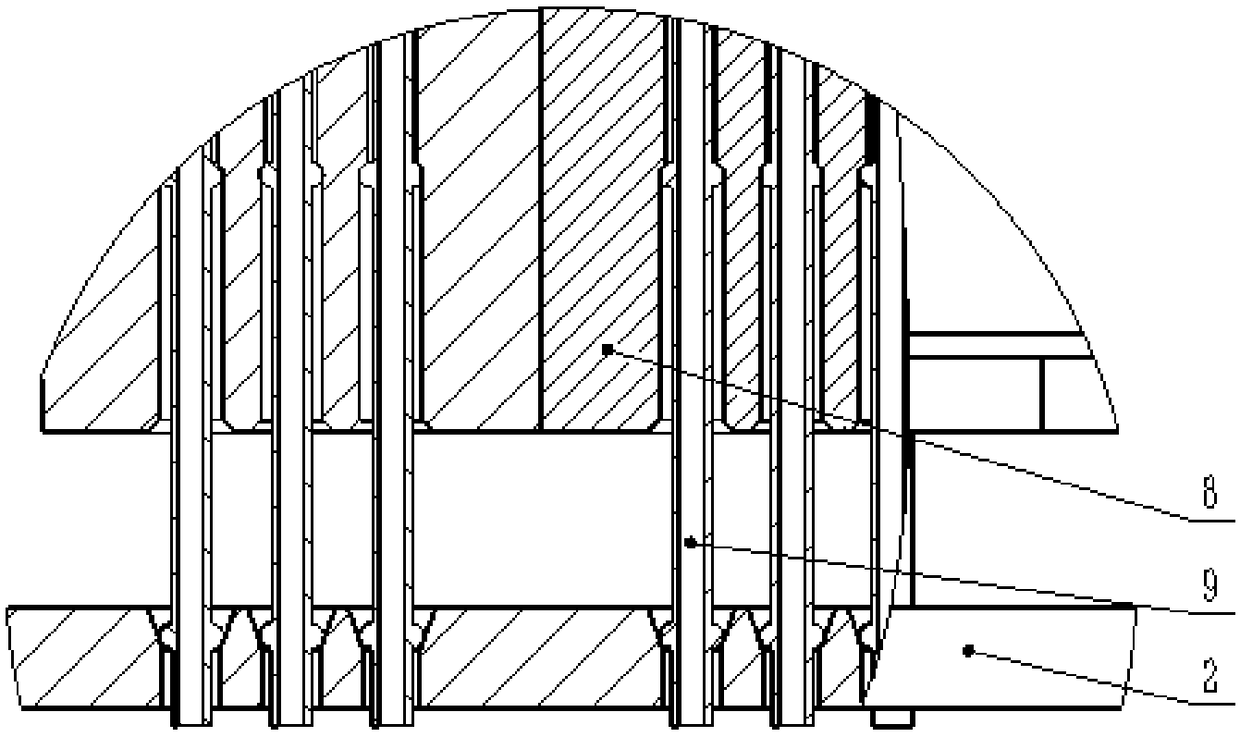

[0028] In this embodiment, the male end 1 of the capillary multi-channel module includes a crimping plate 2, a channel splint 4 and a lower connecting plate, the crimping plate and the channel splint are connected together through the lower connecting plate, and the capillary multi-channel module male end 1 is installed on the channel splint 4 There are a plurality of ventilation module male end units 8 , and the crimping plate 2 of the capillary multi-channel module male end 1 is provided with a plurality of ventilation male end pins 9 inserted into the ventilation module male end units 8 .

[0029] In this embodiment, the female end 10 of the capillary multi-channel module includes a ...

Embodiment 2

[0034] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0035] Such as Figure 4 As shown, the locking device in this embodiment includes a guide column 5 installed on the lower connecting plate, and the upper connecting plate is provided with a pin hole that is compatible with the guiding column 5. The guiding column is to connect the male end pin of the device with the female The end pins are aligned vertically. The lower connecting plate is provided with a rotating bayonet 7, the rotating bayonet 7 is connected with a buckle 6, and the upper connecting plate is connected with a fixed bayonet 12 compatible with the buckle 6. A through hole is provided on the buckle 6, and a threaded rod 17 is installed in the through hole. There are springs 15 . When locking, rotate the buckle 6, and when the circular arc of the profiling rod 16 fits with the fixed bayonet pin 12, turn the handle ball to the right, and the threaded rod 17 compresses the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com