Bi-parting type membrane bearing cylinder for improved stress and strain type triaxial apparatus

A stress-strain, triaxial instrument technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of cumbersome operation steps, damage to the sample, poor sealing, etc., and achieves convenient use, simple and reasonable structure, and easy cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

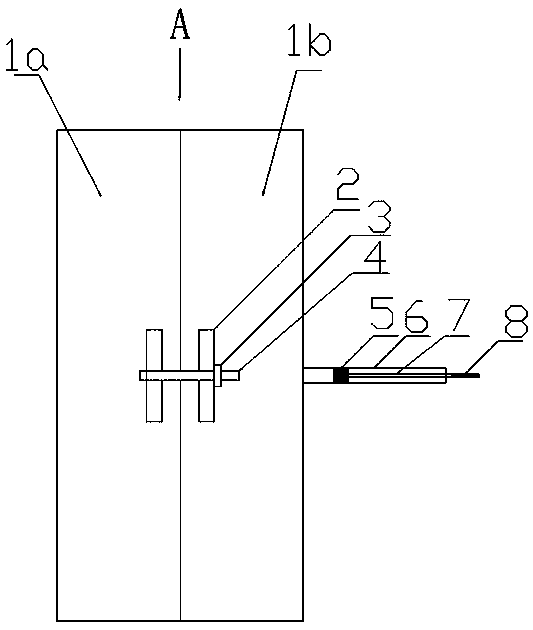

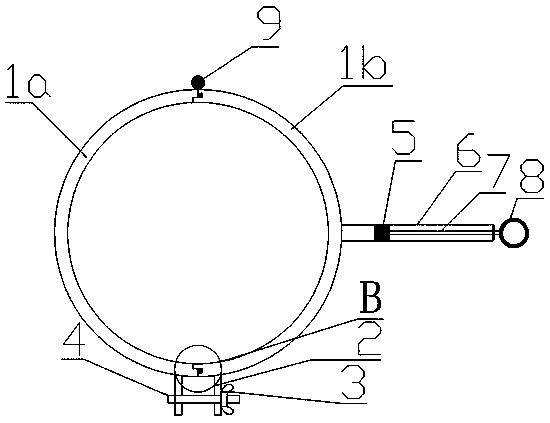

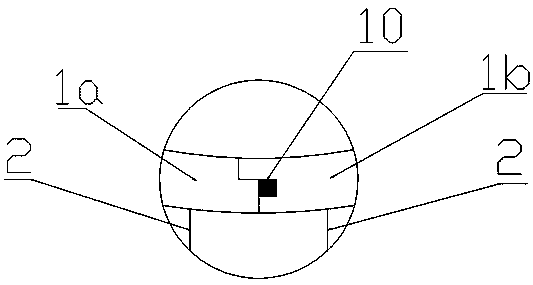

[0019] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention includes a cylinder body, lugs 2, nuts 3, bolts 4, piston 5, exhaust pipe 6, piston rod 7, pull ring 8, hinge 9 and sealing rubber strip 10, and the cylinder body includes a left The semi-cylindrical body 1a and the right semi-cylindrical body 1b, the left semi-cylindrical body 1a and the right semi-cylindrical body 1b are hinged by hinges 9, the left semi-cylindrical body 1a and the right semi-cylindrical body 1b all have hanging ears 2, the left semi-cylindrical body 1a and the right semi-cylindrical body 1b all have hanging ears The other side of the semi-cylindrical body 1a and the right semi-cylindrical body 1b are combined together through the lug 2, the bolt 4 and the nut 3, and the butt joint of the left semi-cylindrical body 1a and the right semi-cylindrical body 1b is provided with a positioning stop and embedded in the positioning The sealing strip 10 of the groove of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com