Bamboo column building material processing method

A processing method and technology of building materials, applied in wood processing equipment, sugarcane mechanical processing, wood compression, etc., to achieve the effect of improving technological content and product added value, obvious competitive advantage, improving appearance quality and scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

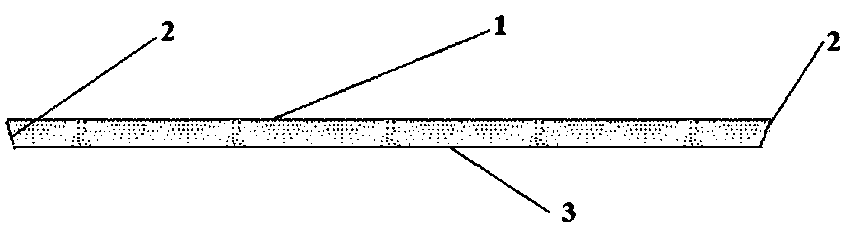

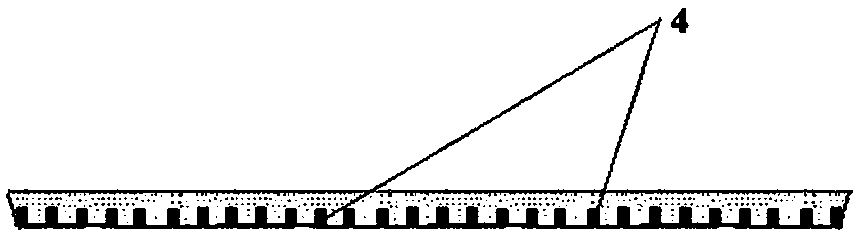

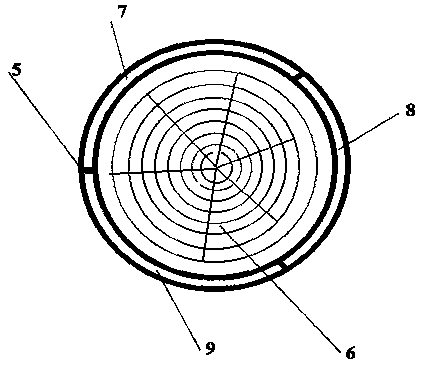

[0032] The concrete steps of a kind of processing method of bamboo column building material are:

[0033] Step 1: The moso bamboo is made into a flattened bamboo board by an extrusion flattening process. The production length is 2 meters, the width is a natural width, and the thickness of the moso bamboo flattened bamboo board is 8mm, and sent to a drying kiln to be dried to a moisture content of less than 10wt %, for standby use; the described extrusion flattening processing method refers to the Chinese invention patent application text with application number 201610894789.9;

[0034] Step 2: Strip the bark of the freshly cut Chinese fir logs, send them to a drying kiln to dry to a moisture content of less than 10wt%, cut them into the required length of cylinders, and send them to a rotary cutting machine to be processed into cylinders with a diameter of 20cm for use. ;

[0035] Step 3: Select the moso bamboo produced in step 1 to flatten the bamboo board, send it to the pu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap