Wallboard production mould vehicle with autogenous curing function

A self-maintenance, mold car technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of backward wallboard production level and production efficiency, quality and efficiency can not keep up with market demand, etc. Mold time, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

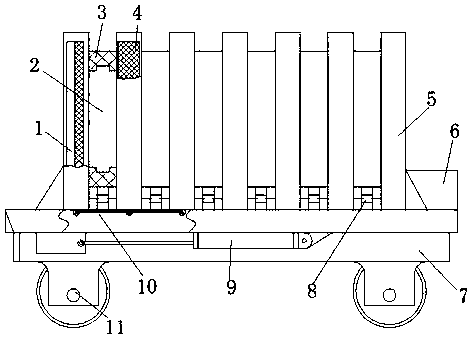

[0020] refer to Figure 1-2 , a wall panel production mold car with self-maintenance function, comprising a self-propelled mold vehicle chassis 1 The top of the self-propelled mold vehicle chassis 1 is provided with a fixed chute, and a heat-insulating mold frame 3 and a heat-insulating middle partition 4 are placed in the chute and the thermal insulation opening and closing template 7, and the thermal insulation mold frame 3, the insulation middle partition 4 and the thermal insulation opening and closing template 7 are slidingly matched with the chassis 1 of the self-propelled molding vehicle, and the top of the chassis 1 of the self-propelled molding vehicle is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com