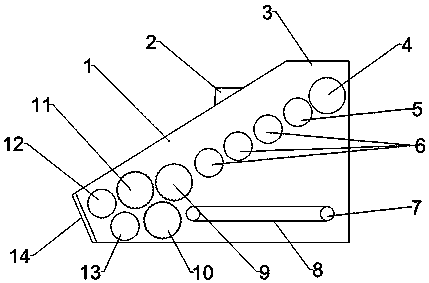

Automatic dough pressing machine

A dough pressing machine, an automatic technology, applied in the dough forming machinery or equipment, dough sheeter/rolling machine/rolling pin, baking, etc., can solve the problem that the hygiene of manual dough pressing cannot be guaranteed and the structural tightness is inconsistent. , large changes in fabric thickness, etc., to achieve the effect of compact structure, compact structure and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] First, the fabric is loaded into the machine body 1 through the material inlet 3, and one end of the fabric is clamped by the clamping roller 4 and the idler wheel 5, and the other end of the fabric hangs down freely to the conveyor belt 8 and is sent to the curved surface pressing roller A9, the curved surface pressing roller Knead the dough for the first time between B10, and then turn to the same curved roller C11 and curved roller A10 as the curved roller B10 for the second kneading. Since the surface of the roller is curved, the dough will not only knead during rolling. Subjected to longitudinal extrusion and stretching, and lateral extrusion and stretching of the axial component force, the stress distribution in each direction is relatively uniform, so that the fabric is uniform in texture and compact in structure, and then conveyed by the surface feeding wheel 6 When the idler 5 is folded and piled up, enter the next cycle of calendering, repeatedly kneading and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com