Connecting structural component for a track

A technology for connecting structures and tracks, which is applied in the field of rail transit, can solve the problems such as the inconvenient adjustment of the installation height of track beams, and achieve the effects of ensuring support strength, improving ride comfort, and ensuring levelness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The invention will be further described below in conjunction with specific embodiments.

[0042]

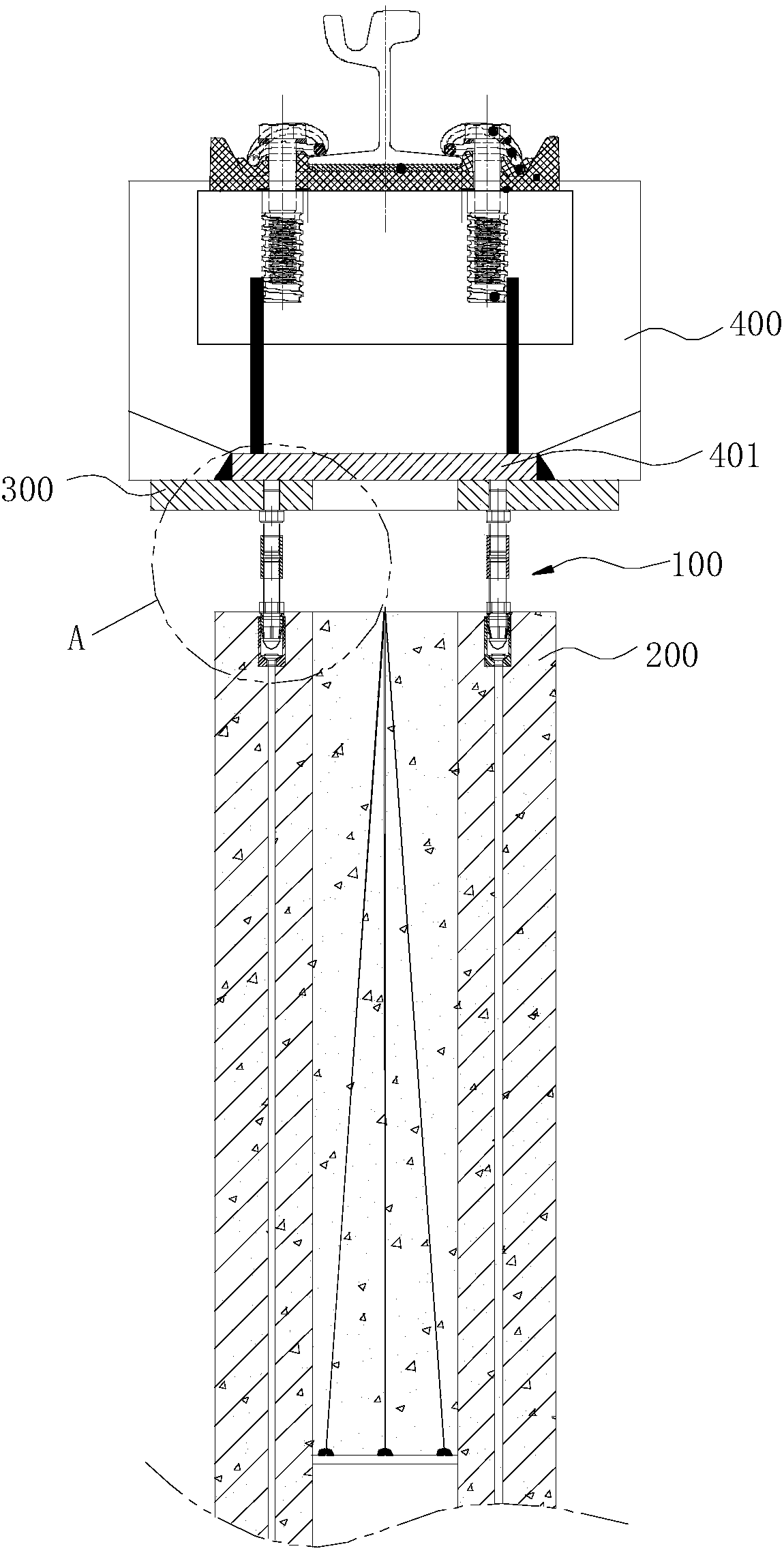

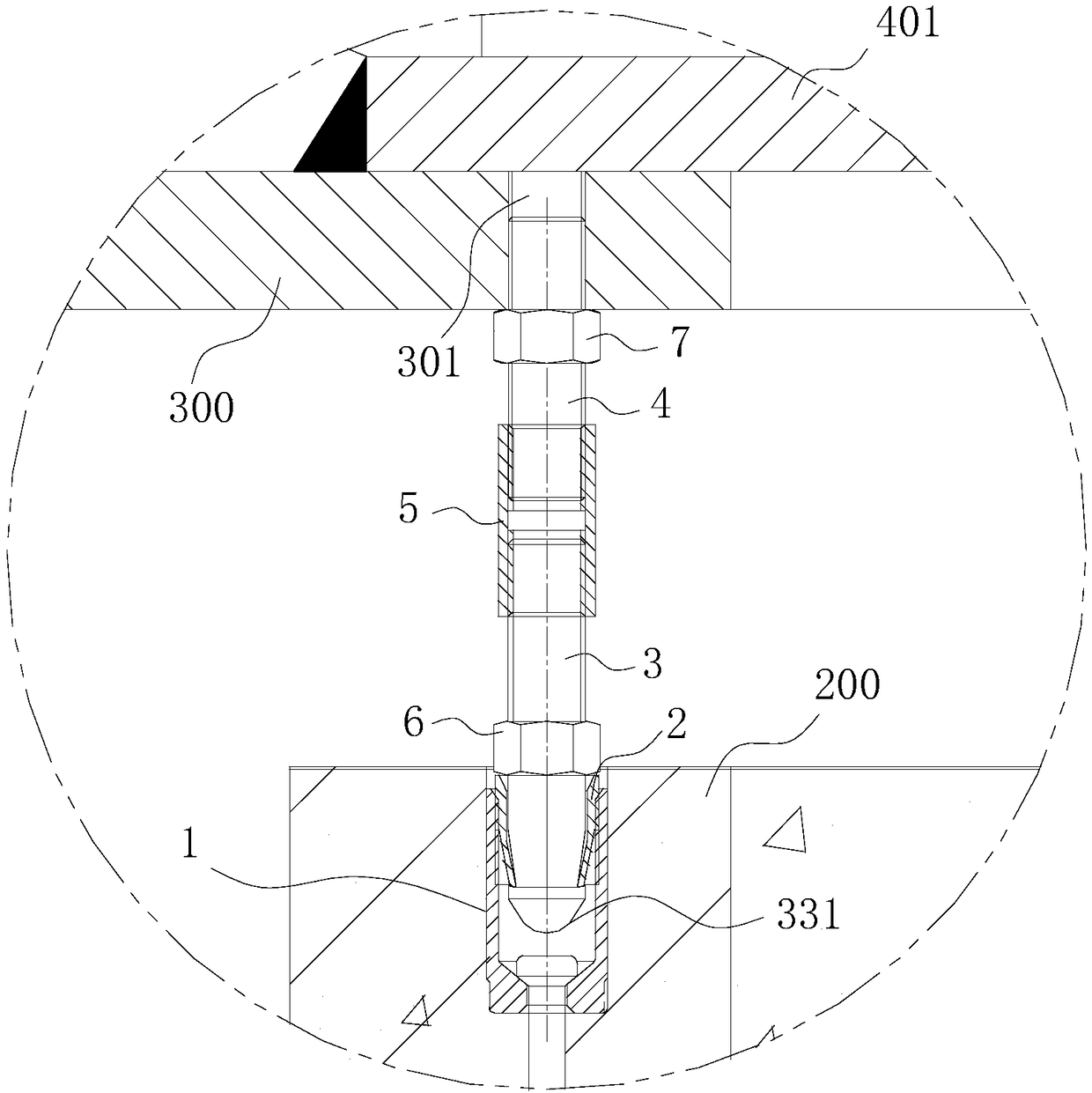

[0043] Such as figure 1 As shown, the track beam 400 laid along the track extension direction has a bottom mounting plate 401 made of metal material, and the bottom mounting plate 401 is welded and fixed to the track beam support plate 300 made of metal material or locked by fasteners. Several groups of track connecting structural members 100 are evenly distributed on the top of the pipe pile 200 to connect the track beam support plate 300 .

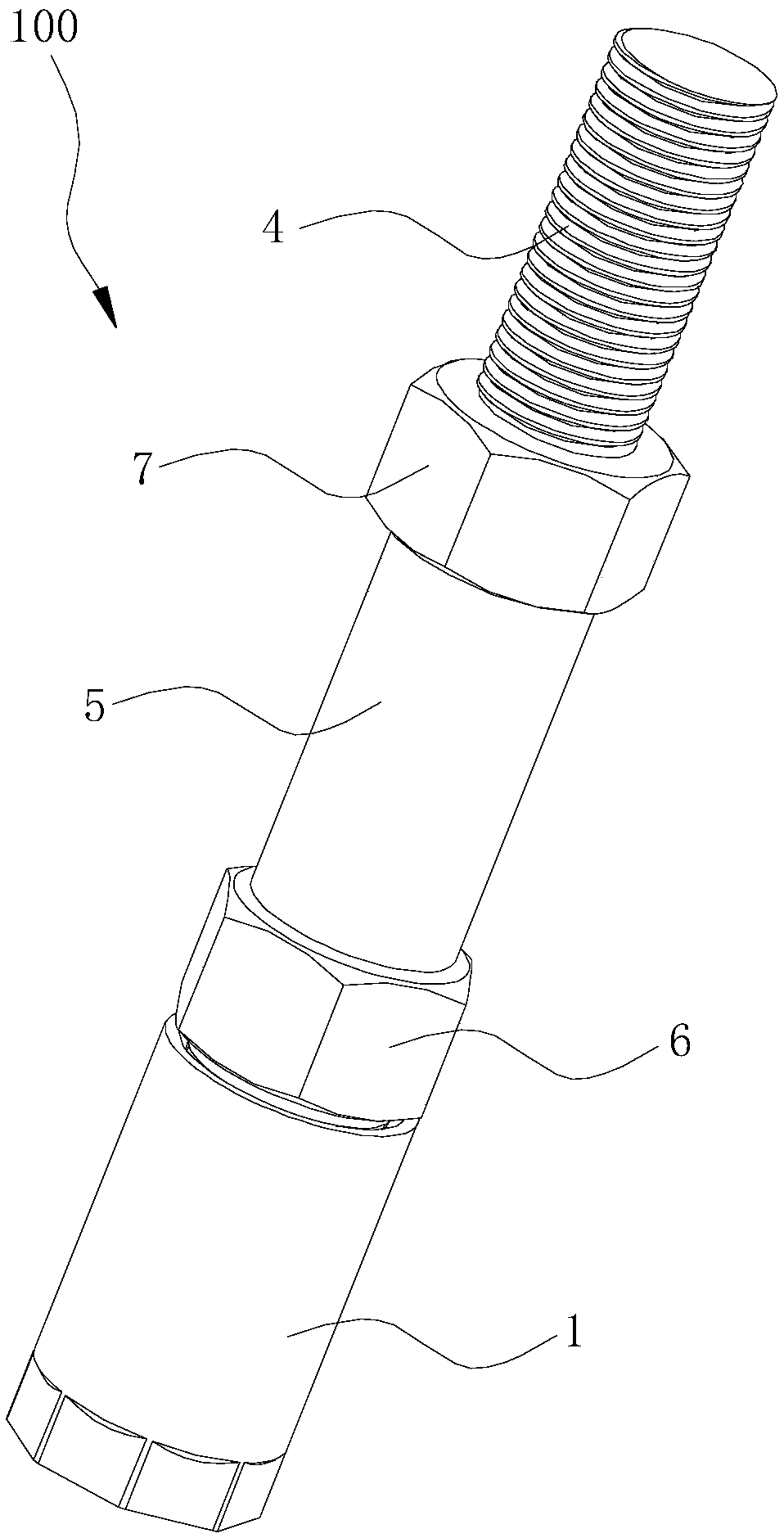

[0044] Such as Figure 2 to Figure 4 As shown, the rail connection structure 100 includes: a nut joint 1, a button barrel 2, a lower connecting rod 3, an upper connecting rod 4, a screw joint 5, a first fastening nut 6 and a second fastening nut 7. Among them, the nut joint 1 is embedded in the end of the pipe pile 200, and the nut joint 1 is tensioned and fixed by a rigid bar (such as a steel rod) embedded in the pipe pile 200....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com