An expansion rivet

An expansion rivet and riveting technology, applied in rivets and other directions, can solve the problems of riveting force reduction and loosening, and achieve the effect of good tensioning reliability and long-term use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

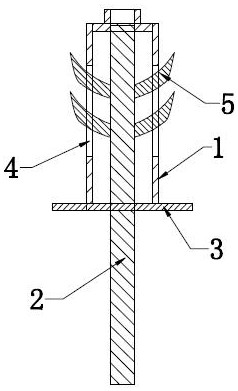

[0012] The expansion rivet of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] As shown in the figure, the expansion rivet of the present invention includes a head 1 with a sleeve structure and a stem 2 protruding from the head. The top end of the stem 2 is limited on the head, and the middle of the head 1 is provided For the flange 3 of the compression riveted part, the circumference of the head 1 is provided with long grooves 4 arranged longitudinally along the surface of the sleeve, and a section of the rod 2 extending into the head is provided with grooves arranged along the circumference of the rod. Conical teeth 5, the conical teeth 5 are arranged along the circumference of the rod and correspond to the positions of the long slots, the said conical teeth 5 extend out of the inner cavity of the sleeve, and the protruding length of the conical teeth 5 is not greater than the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com