Robot and inventory management method thereof

A technology of inventory management and robots, which is applied in the field of robots and their inventory management, can solve the problems of rising manpower and material costs, failure of identification and counting methods, unsightly products, etc., and achieve the effect of improving accuracy and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

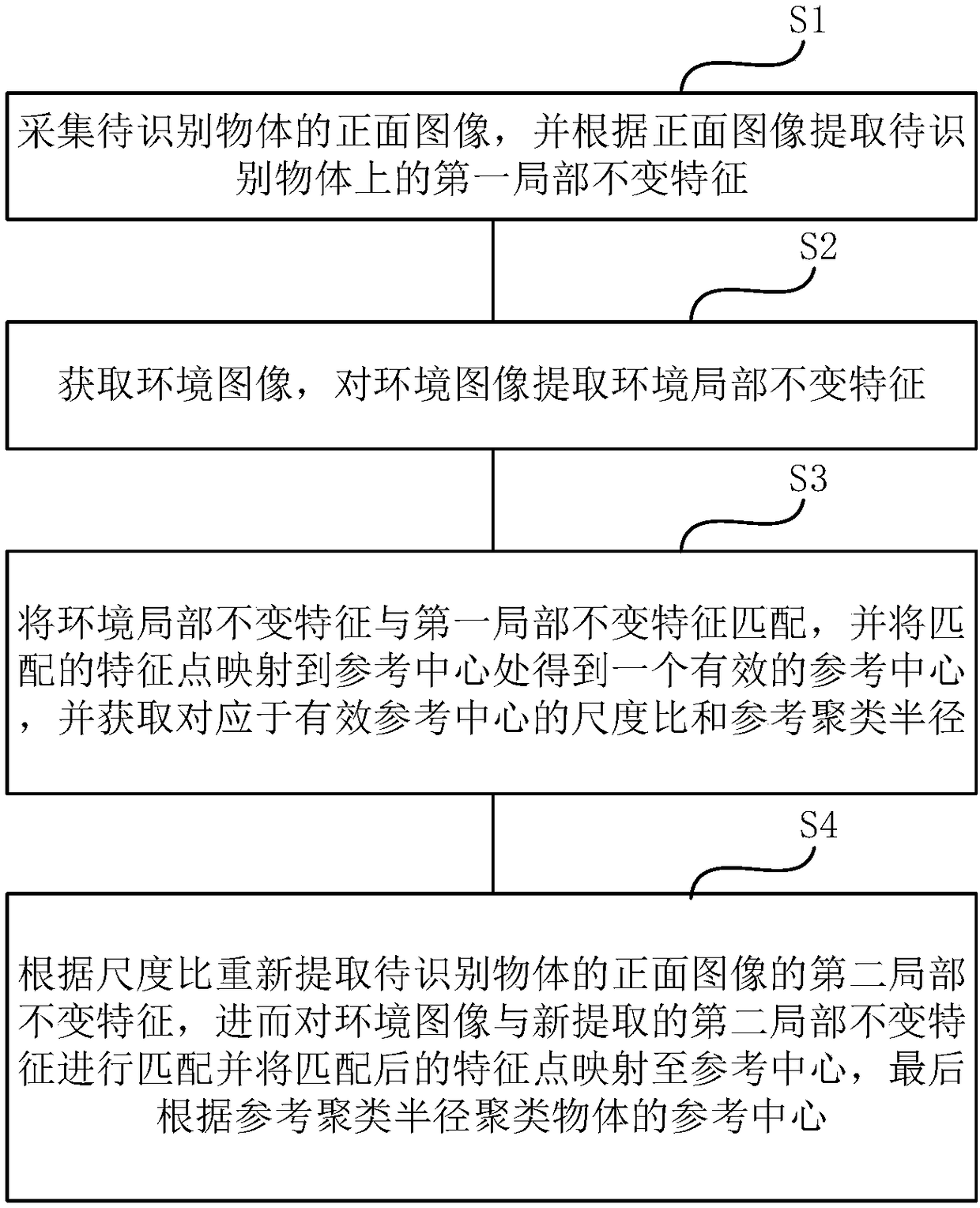

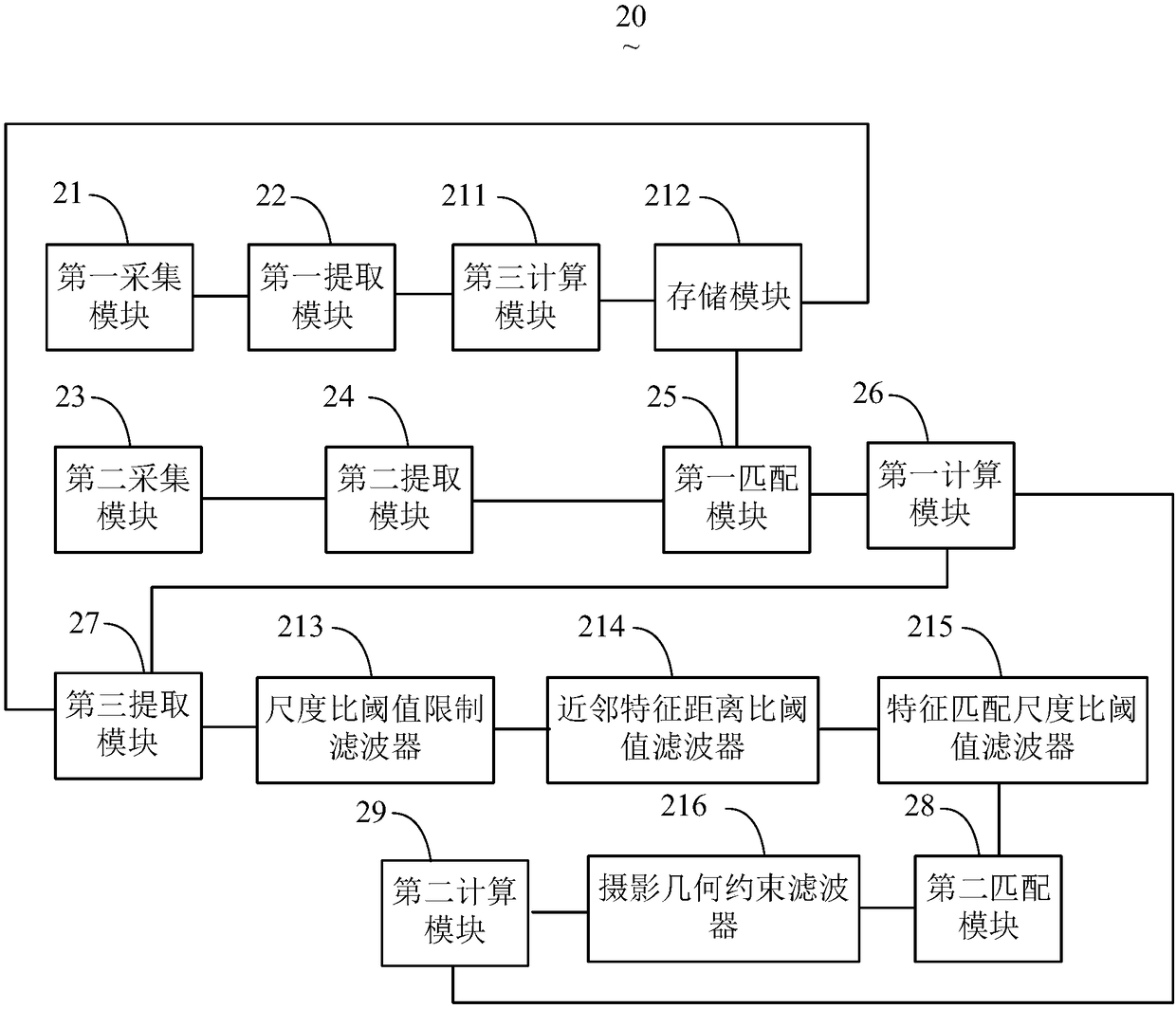

[0044] Please also refer to figure 1 , figure 1 It is a flow chart of a robot inventory management method provided by an embodiment of the present invention. Such as figure 1 As shown, the inventory management method of this embodiment includes two phases: an offline training phase and an online detection phase, wherein the following step S1 is an offline training phase, and steps S2 to S4 are an online detection phase, wherein the offline training phase is used to treat The identified object is modeled, and a two-layer probability density estimation method is provided in the online detection stage, which completes the identification and detection of the object to be identified from coarse to fine. The first-level probability density estimation method is used for coarse detection to obtain significant scale ratios, and the effective reference clustering radius is calculated according to the scale ratio; the second-level probability density estimation method is used for fine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com