Method for winding polar group of valve-regulated lead acid storage battery and special apparatus for same

A technology of lead-acid batteries and pole groups, which is applied in the construction of lead-acid batteries, lead-acid batteries, battery electrodes, etc. It can solve the problem that the pole spacing of the inner ring of the pole group becomes smaller, affects the performance of the battery, and cannot guarantee the acid absorption of the plates, etc. problem, achieve the effect of improving battery performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

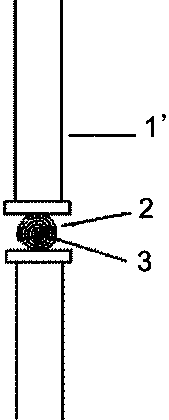

[0017] figure 1 Middle, pressure bar 1 ’ , Polar plate material 2, roll mandrel 3.

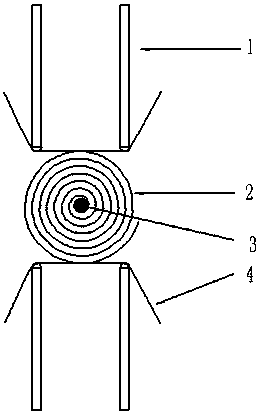

[0018] figure 2 In this case, the belt 4 circulates on the force arm 1. When the pole group is wound, the belt 4 contacts the plate material 2. The friction between the belt 4 and the plate material 2 drives the plate material 2 to rotate, and the plate material 2 drives it. The reel spindle 3 rotates. Can successfully solve the current shortcomings of continuous increase in core winding pressure during winding.

[0019] Because the tension of the belt 4 is controlled by the force arm 1 to be constant, the force acting on the plate is always in a constant state.

[0020] Each time the winding mandrel 3 completes one revolution, the motor can accurately control the rising height of the moment arm 1 within this time according to the pulse of the rotating shaft, that is, the belt 4 synchronously rises to a constant height, and this height is the pole group pole distance. This winding method can ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com