Self-propelled, full-automatic and efficient fruit harvester for double line width ridge planting

A large ridge double-row, fully automatic technology, applied to harvesters, pickers, agricultural machinery and tools, etc., can solve the problem of unrelated harvesting machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

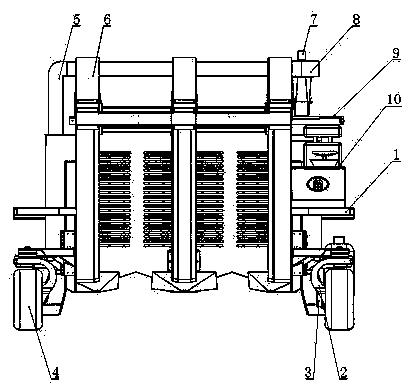

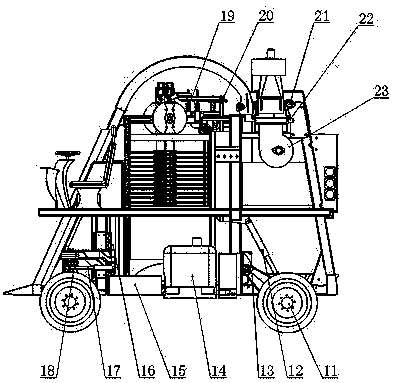

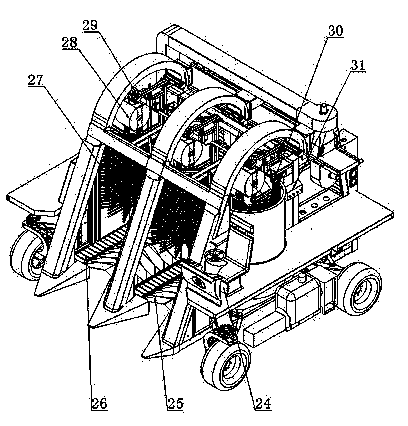

[0016] Specific embodiments: The best embodiment of the patent of the present invention will be described in detail below in conjunction with the accompanying drawings. The self-propelled large ridge double-row fully automatic high-efficiency fruit harvester consists of: frame body 1, front wheel motor frame 2, front wheel hydraulic motor 3, Walking wheel 4, dust removal air cylinder 5, upper arch slideway 6, fan hydraulic motor 7, dust removal suction fan 8, fruit horizontal conveying device 9, control device 10, rear wheel hydraulic motor 11, rear wheel telescopic oil cylinder 12, rear wheel motor Frame 13, engine 14, hydraulic pump 15, front leg telescopic oil cylinder 16, front leg steering oil cylinder 17, front leg telescopic jacket 18, vibration rake amplitude adjustment device 19, vibration support 20, upper arch slideway conveyor belt hydraulic motor 21, Fruit horizontal conveying device hydraulic motor 22, dust removal blower 23, power supply device 24, fruit fish sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com