A low absorption/emission ratio adaptive temperature control material and its preparation method

A self-adaptive, low-absorbing technology, applied in the field of new materials, can solve the problems of restricting thermal control ability, limited application, complex structure, etc., and achieve the effect of optimizing material components and processes, expanding application fields, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

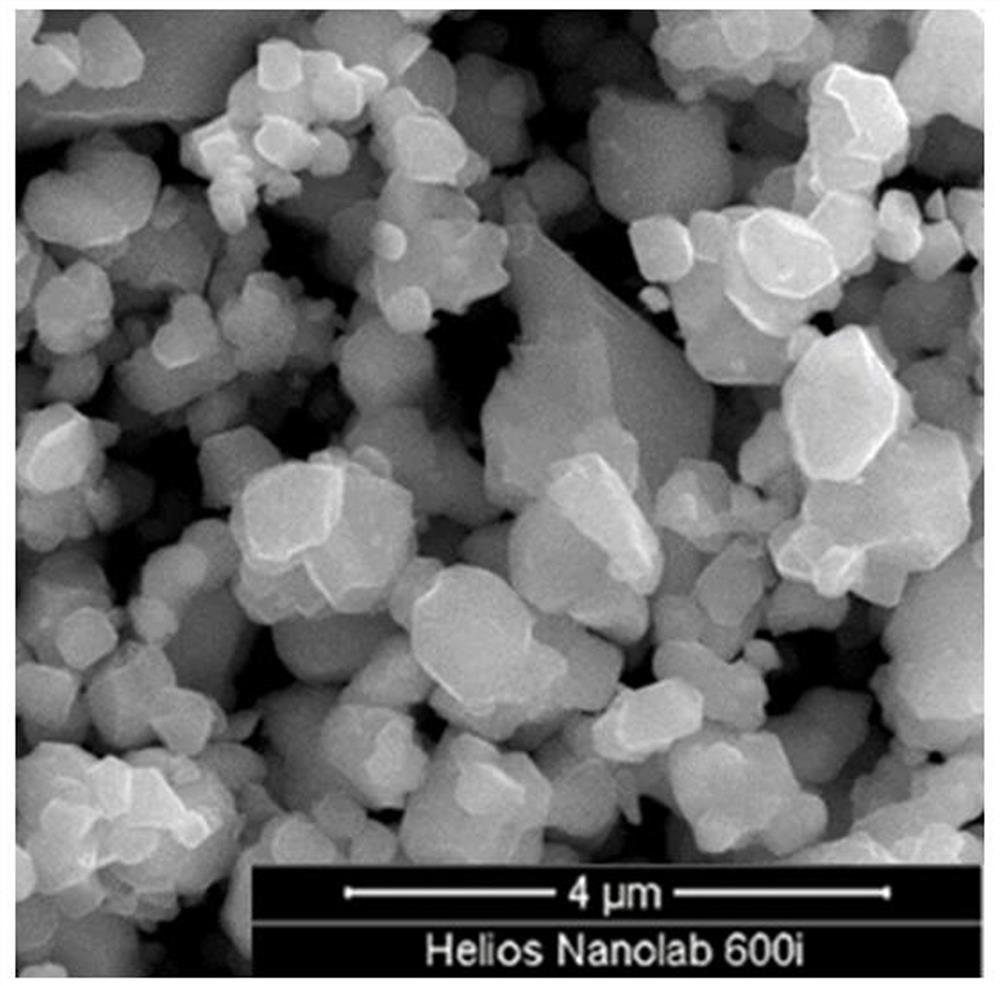

Image

Examples

Embodiment 1

[0024] 1) According to the stoichiometric ratio Ba y A x TiO 3 Weigh 1mol TiO 2 Powder, 0.4mol strontium carbonate (component A), 0.6mol barium carbonate, the purity of the three is >99.9%, and the particle size of the powder is in the submicron size;

[0025] 2) Mix the powder weighed in step 1) with agate balls and water in a volume ratio of 1:1:1, put them into an agate ball mill jar, mix and grind them with a planetary ball mill for 24 hours, take them out, and dry them at 100°C;

[0026] 3) Pass the powder in step 2) through a 100-mesh sieve, put it into a corundum crucible and place it in a muffle furnace, pre-fire at 1000°C for 1 hour, and cool to room temperature with the furnace;

[0027] 4) Take out the powder in step 3) and put in 0.005mol Al 2 o 3 and 0.024mol nano-SiO 2 , put it into the agate jar again for ball milling for 10 hours, take it out and dry it

[0028] 5) Add the powder in step 4) to granulate with polyvinyl alcohol aqueous solution (concentrat...

Embodiment 2

[0031] 1) Weigh 1mol TiO 2 Powder, 0.7mol Ba carbonate (barium carbonate), 0.3mol Sr carbonate (strontium carbonate A component), powder purity>99.9%, particle size in submicron size;

[0032] 2) Mix the powder weighed in step 1) with agate balls and ethanol at a volume ratio of 1:1:1, put them into an agate ball mill jar, mix and grind them with a planetary ball mill for 24 hours, take them out, and dry them at 100°C;

[0033] 3) Pass the powder in step 2) through a 100-mesh sieve, put it into a crucible and place it in a muffle furnace, pre-fire at 1150°C for 0.5h, and cool to room temperature with the furnace;

[0034] 4) Take out the powder in step 3) and put in 0.003mol Al 2 o 3 , 0.002mol MnO 2 and 0.02mol nano-SiO 2 , put it into the agate jar again for ball milling for 10 hours, take it out and dry it

[0035] 5) Add the powder in step 4) to granulate with polyvinyl alcohol aqueous solution (concentration 1at%), the amount of polyvinyl alcohol aqueous solution add...

Embodiment 3

[0038] 1) Weigh 1mol TiO 2 , 0.6mol barium carbonate, 0.3mol strontium carbonate, 0.1mol tin carbonate, powder purity>99.9%, particle size in submicron size;

[0039] 2) Mix the powder weighed in step 1) with agate balls, water or ethanol at a volume ratio of 1:1:1, put them into an agate ball mill jar, mix and grind them with a planetary ball mill for 24 hours, take them out, and dry them at 100°C;

[0040] 3) Pass the powder in step 2) through a 100-mesh sieve, put it into a corundum crucible and place it in a muffle furnace, pre-fire at 1100°C for 1 hour, and cool to room temperature with the furnace

[0041] 4) Take out the powder in step 3) and put in 0.001mol Al 2 o 3 , 0.002mol MnO 2 and 0.03mol nano-SiO 2 , and then put it into an agate jar for ball milling for 10 hours, take it out and dry it, and pass through a 100-mesh sieve.

[0042] 5) Add the powder in step 4) to granulate with polyvinyl alcohol aqueous solution (concentration 1at%), the amount of polyvinyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com