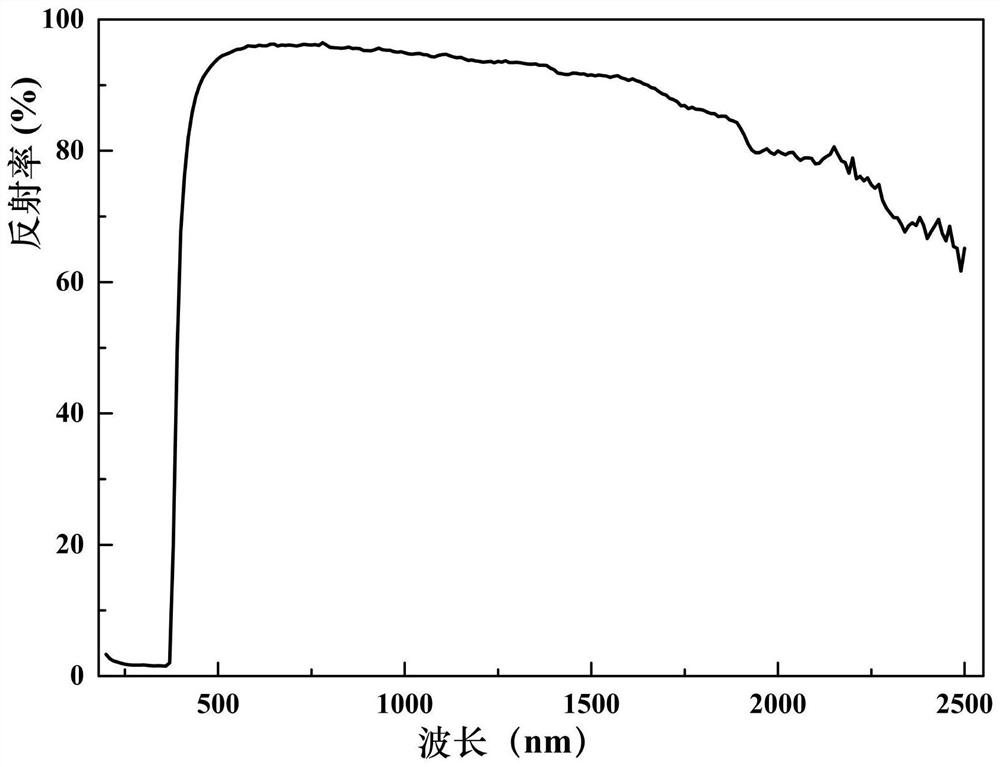

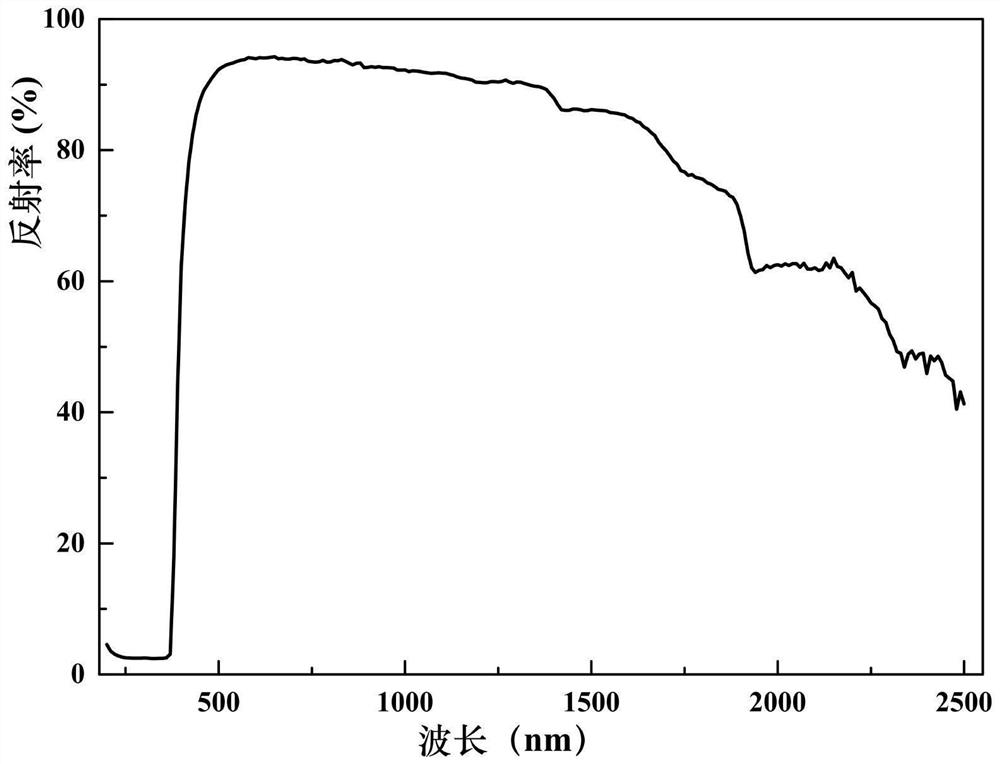

A kind of ultraviolet radiation resistance low absorption rate inorganic white thermal control coating and preparation method thereof

A technology of thermal control coating and low absorption rate, applied in coatings, alkali metal silicate coatings, etc., can solve the problems of low solar absorption ratio and degradation of light-to-heat conversion performance, and achieve the effect of low volatility and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

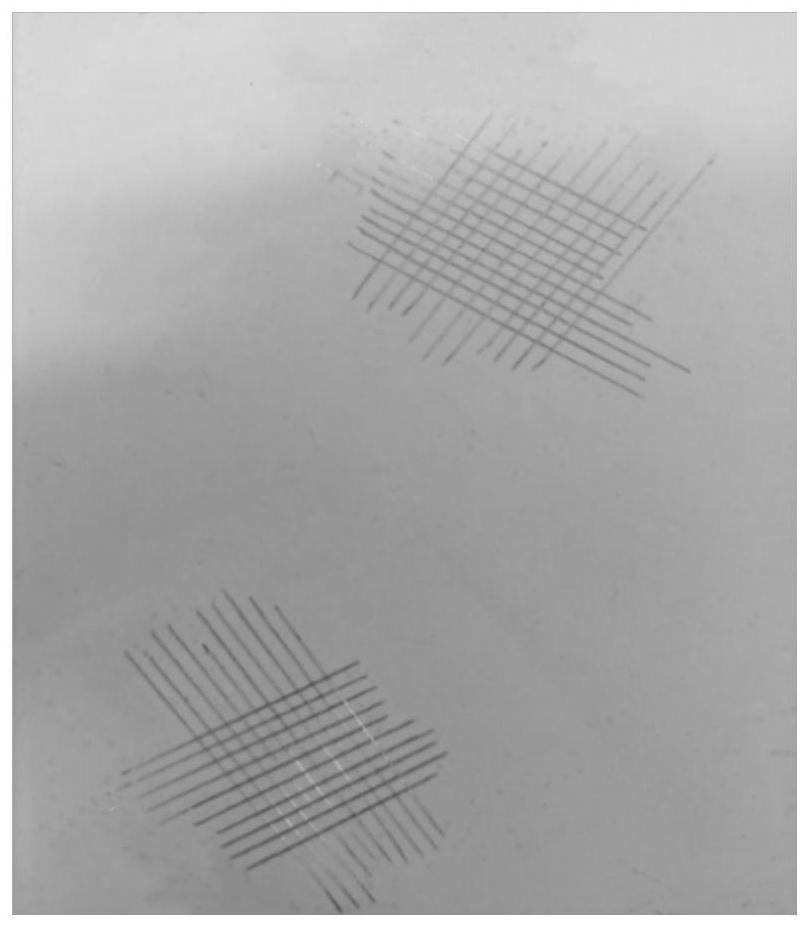

[0027] Embodiment 1: In this embodiment, by mass percentage, the composition of the inorganic thermal control coating is made of the following raw materials: 20.8wt% potassium silicate, 28.9wt% zinc oxide pigment, 0.9wt% polyoxypropylene Oxyethylene glyceryl ether, 5.7 wt% alkylaryl polyether alcohol, 0.3 wt% silicone polyether, 3.6 wt% non-ionic polyurethane and the balance water. Wherein the potassium water glass is obtained by mixing potassium silicate, potassium hydroxide and water according to the mass ratio of 8:0.5g:20.

[0028] The preparation method of the inorganic thermal control coating taking zinc oxide pigment as example, carries out according to the following specific steps:

[0029] At first 20.8wt% potassium silicate, 0.4wt% defoamer polyoxypropylene polyoxyethylene glyceryl ether (Wuhan Nengren Pharmaceutical Chemical Co., Ltd.), 5.7wt% dispersant alkylaryl polyether alcohol (Guangzhou Desong Chemical Co., Ltd.) company, model 405), 0.3wt% substrate wetting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com