Chewing gums containing allulose

A technology of allulose and chewing gum, applied in the direction of chewing gum, food science, application, etc., can solve the problem of low calorie

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

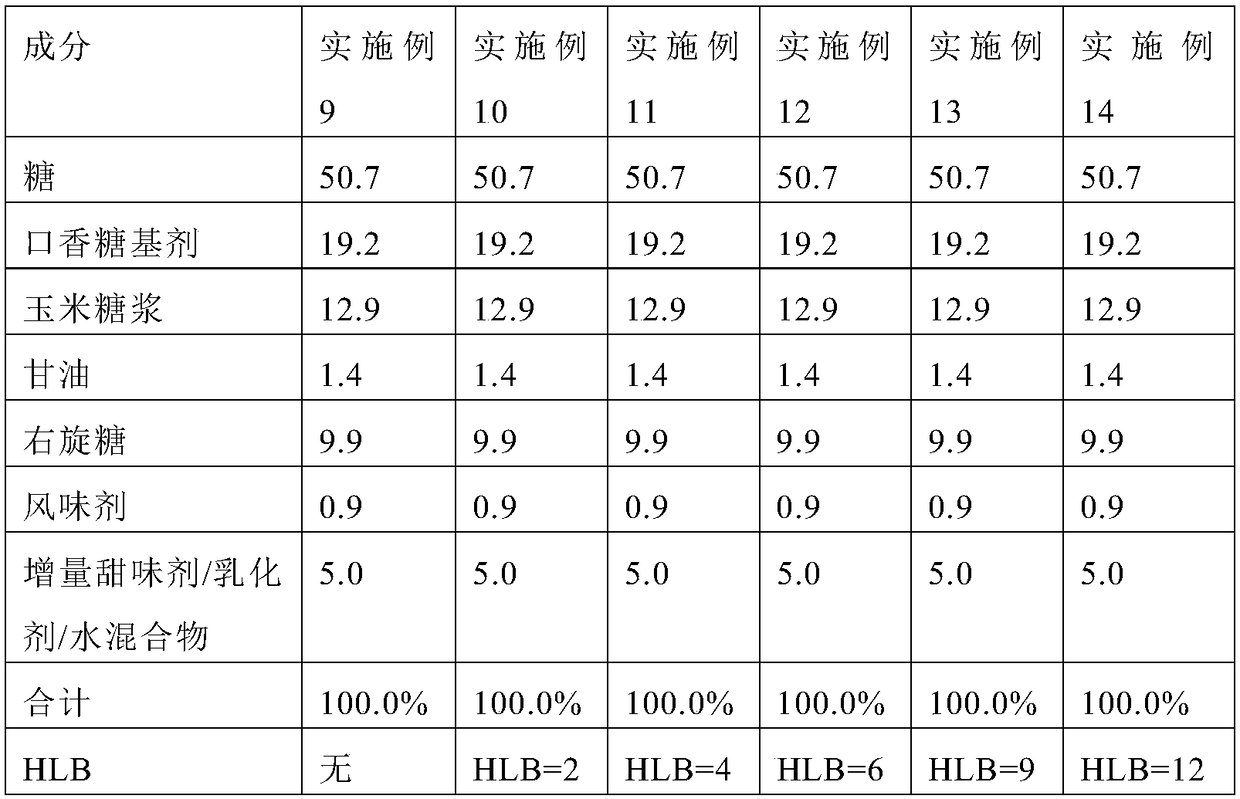

[0054] II. Example

[0055] The following examples and comparative examples of the invention are provided by way of illustration and illustration.

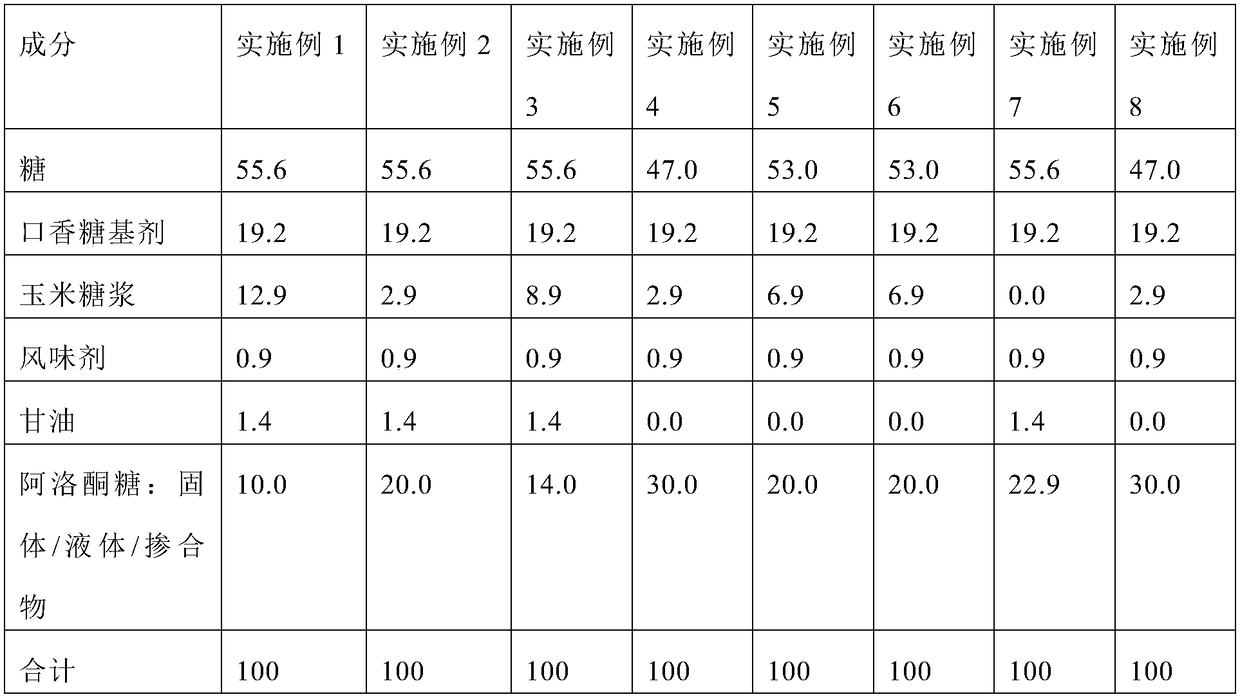

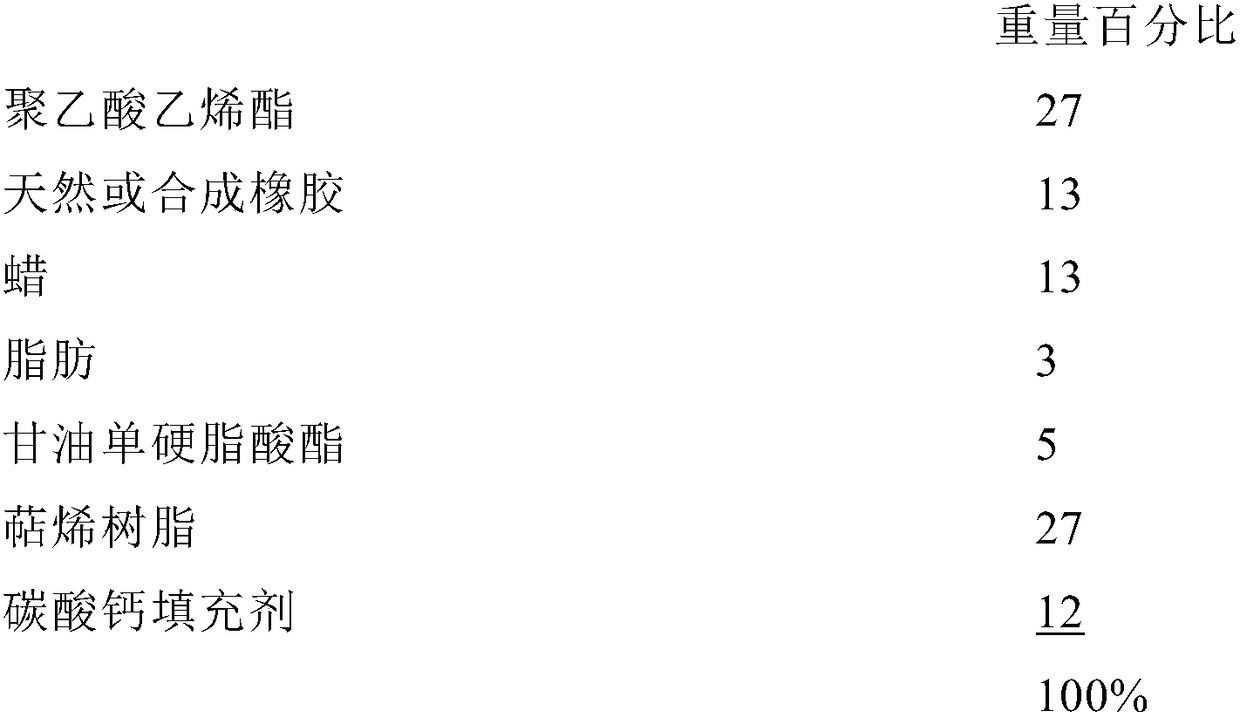

[0056] The formulations listed in Table 1 include various sugar-type formulations in which allulose may be added to chewing gum after dissolving psicose in water and mixing with various aqueous solvents. Additionally, allulose syrups are available from commercial suppliers with different ranges of solids. Adjusting the solids content can alter the physical properties (ie, viscosity) of the psicose syrup to achieve desired processing characteristics or product performance.

[0057] Table 1

[0058] weight percentage

[0059]

Embodiment 1

[0061] Allulose powder can be added directly to the gum.

Embodiment 2

[0063] A 160 gram portion of allulose can be dissolved in 40 grams of water at 40°C to make an 80% solution and added to the chewing gum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com