Homogenized tobacco material production line and method for inline production of homogenized tobacco material

A technology of homogenization and production line, which is applied in the fields of tobacco, tobacco processing, tobacco preparation, etc., can solve the problems of not knowing the precise composition and inappropriateness of tobacco powder, and achieve the effect of easy handling and disposal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

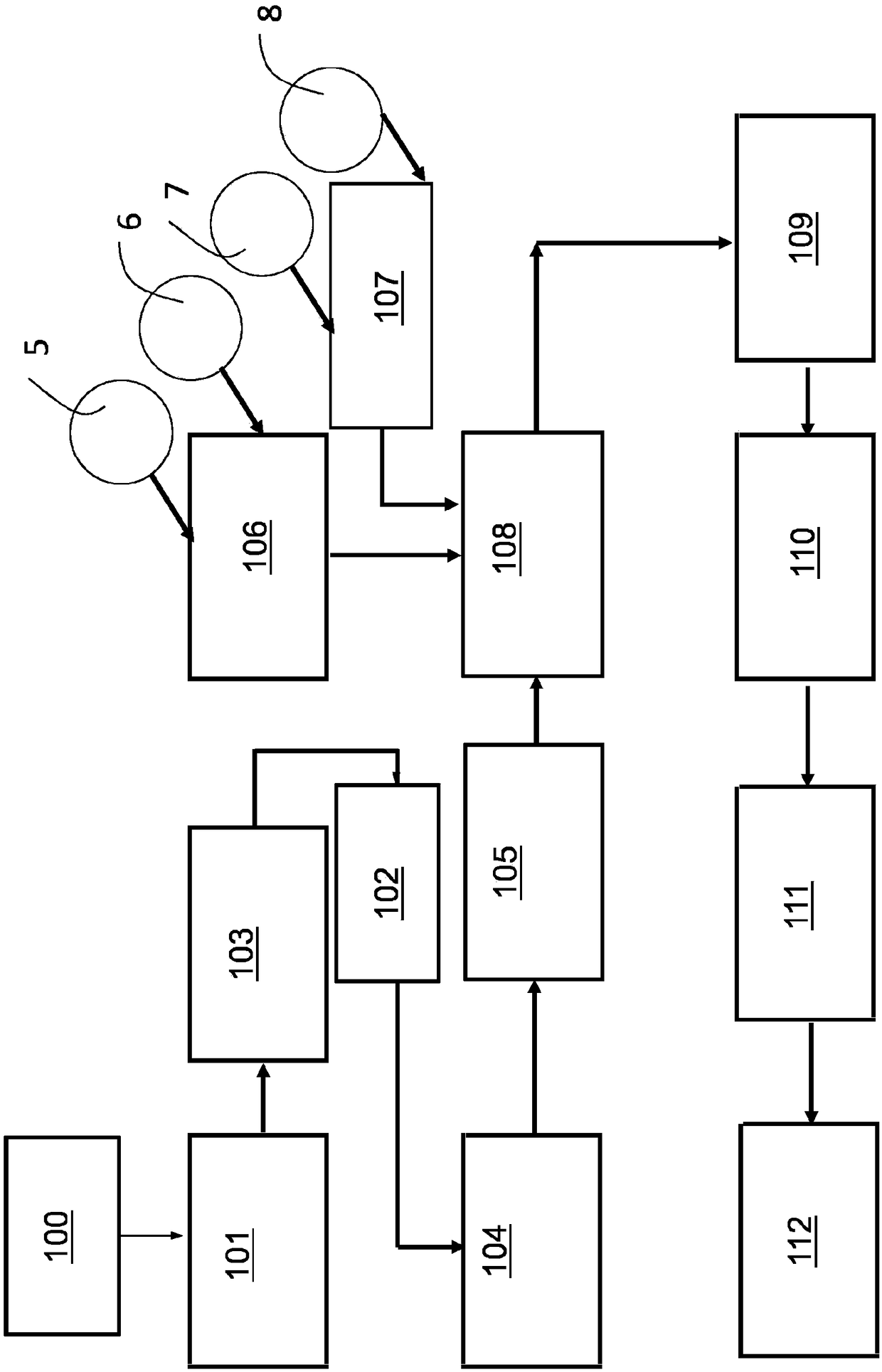

[0089] initial reference figure 1 , presents a method for producing a slurry according to the invention. The first step in the method of the present invention is the selection of the tobacco type and tobacco grade 100 to be used in the tobacco blend used to produce homogenized tobacco material. The types and grades of tobacco used in the methods of the invention are, for example, flue-cured tobacco, sun-cured tobacco, oriental tobacco, and filler tobacco.

[0090] According to the following steps of the method of the invention, only selected tobacco types and tobacco grades intended to be produced for homogenized tobacco material are processed.

[0091] The method comprises a further step 101 of laying the selected tobacco. This step may involve checking tobacco integrity, such as grade and quantity, which may be verified, for example, by barcode readers for product tracking and traceability. After harvesting and curing, tobacco leaves are assigned grades, which describe, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com