Deep drawing tool and deep drawing process for deep drawing blanks

A deep-drawing and tooling technology, applied in the field of deep-drawing tools, can solve the problems of high compressed air manufacturing cost, high compressed air consumption, high noise, etc., and achieve the effect of avoiding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

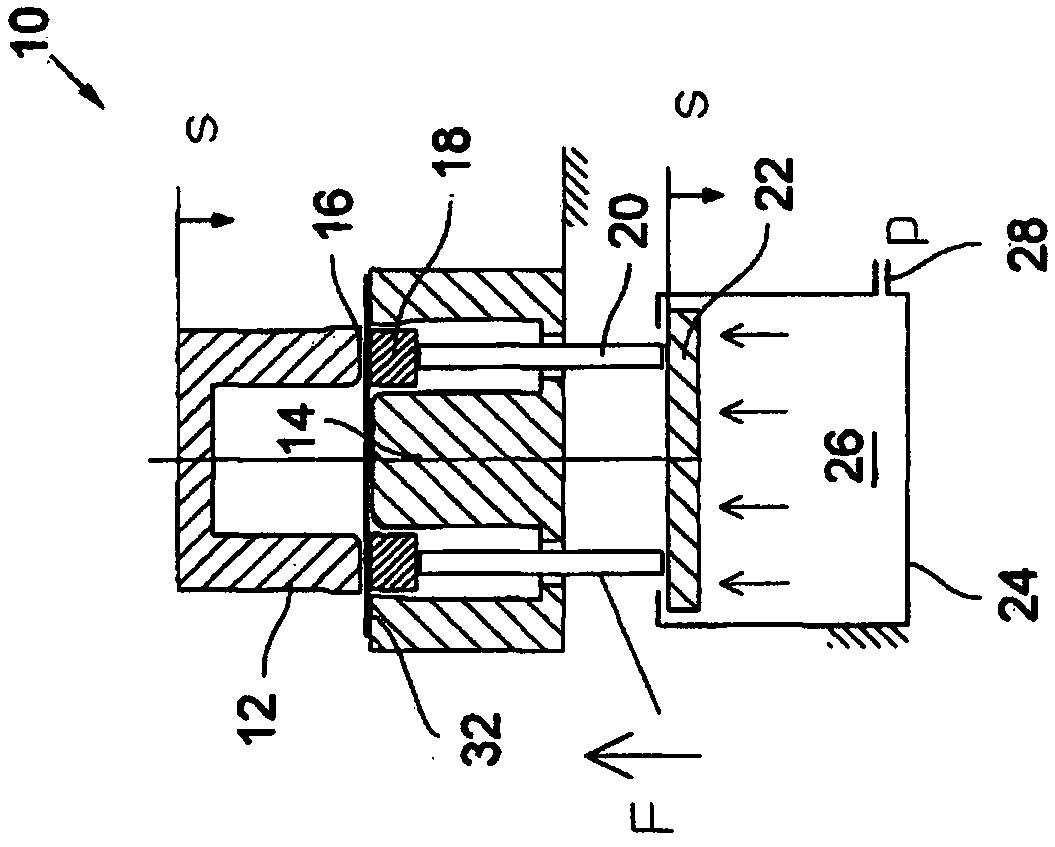

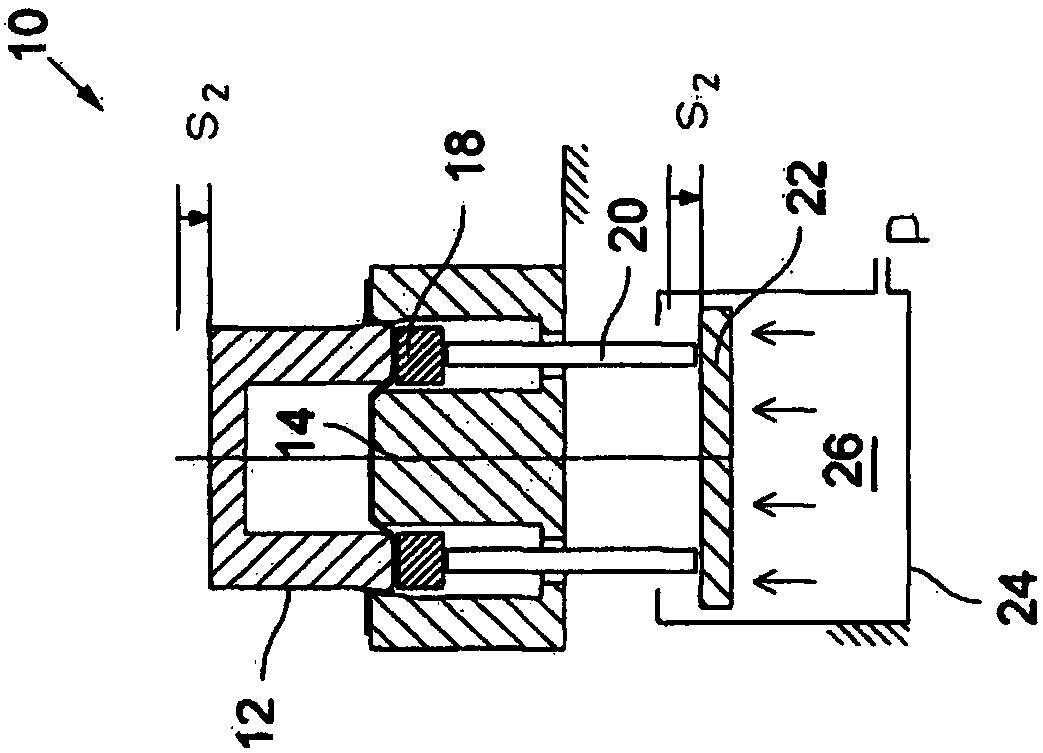

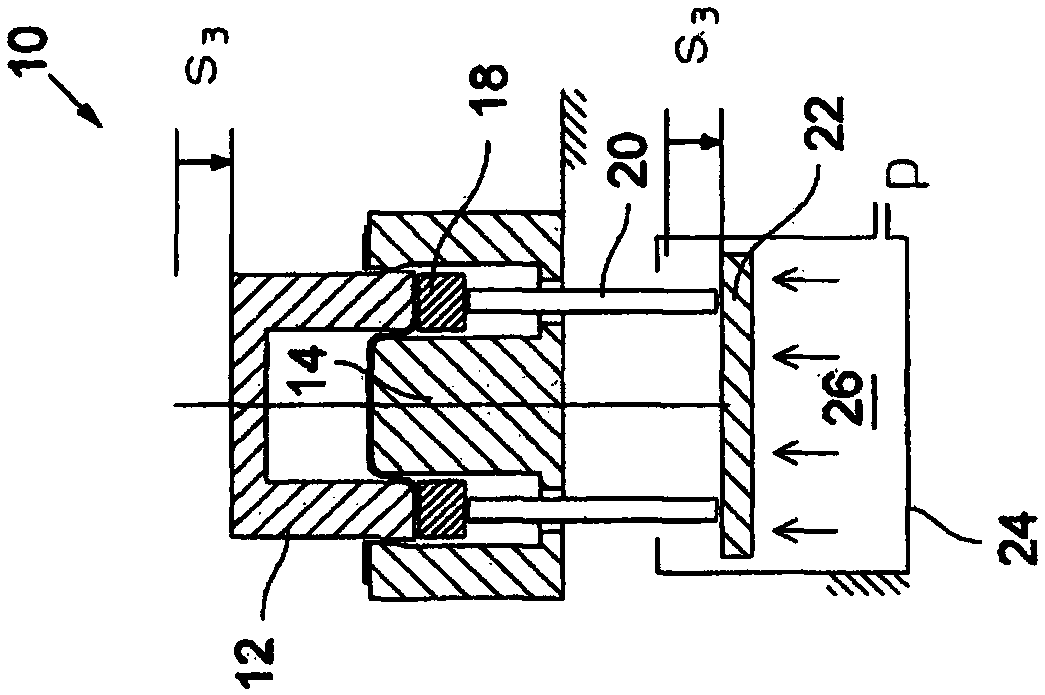

[0032] exist Figures 1a to 1c A deep-drawing tool for deep-drawing blanks stamped from painted or coated sheet metal is depicted in . The deep drawing tool is designated overall by the reference number 10 and has a drawing bell 12 depicted in a sectional view and a drawing core 14 through which the drawing bell 12 is drawn downwards in direction S during deep drawing stretch. The direction S here represents a downward movement towards the lower dead center of the tension bell, which can be driven by a crankshaft drive not shown in detail and can typically, but not exclusively, perform a sinusoidal forward and backward movement, during which Tensile core 14 remains stationary.

[0033]Below the edge 16 of the stretch bell 12, an anti-wrinkle clamp 18 is arranged around the stretch core 14 and can be moved up and down. The anti-wrinkle jig 18 is located on the anti-wrinkle jig rod 20 , and the bottom end of the anti-wrinkle jig rod is connected with a piston 22 embedded in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com