Cleaning device of tubular workpiece

A technology for cleaning devices and workpieces, applied in the field of mechanical processing, can solve the problem that the workpiece is not easy to wash, and achieve the effects of improving cleaning strength, improving impact strength, and avoiding surface wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further detailed explanation through specific implementation mode below:

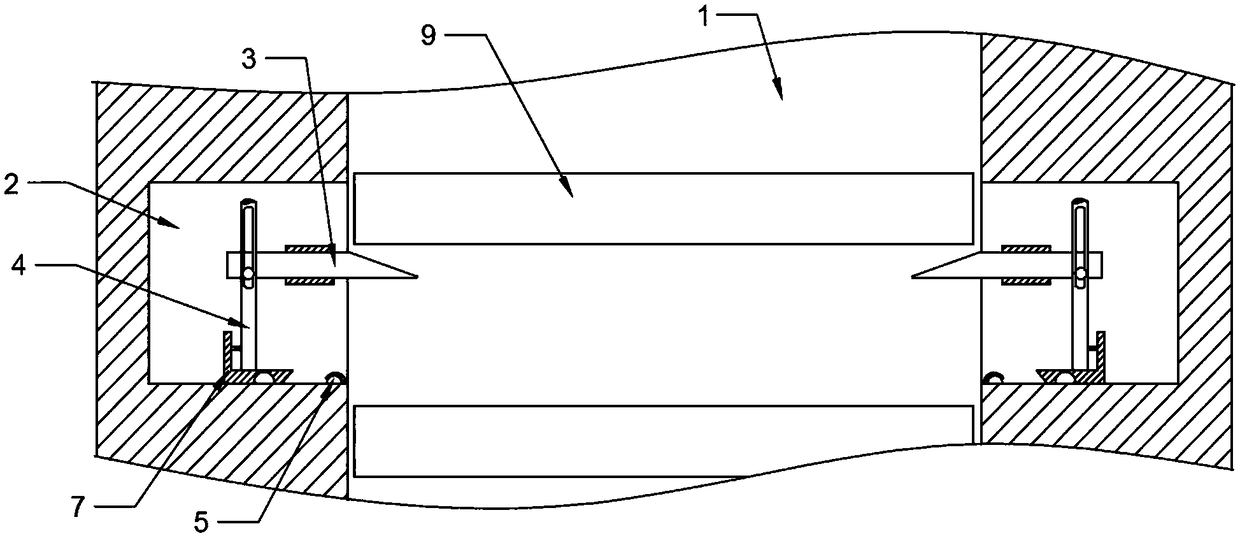

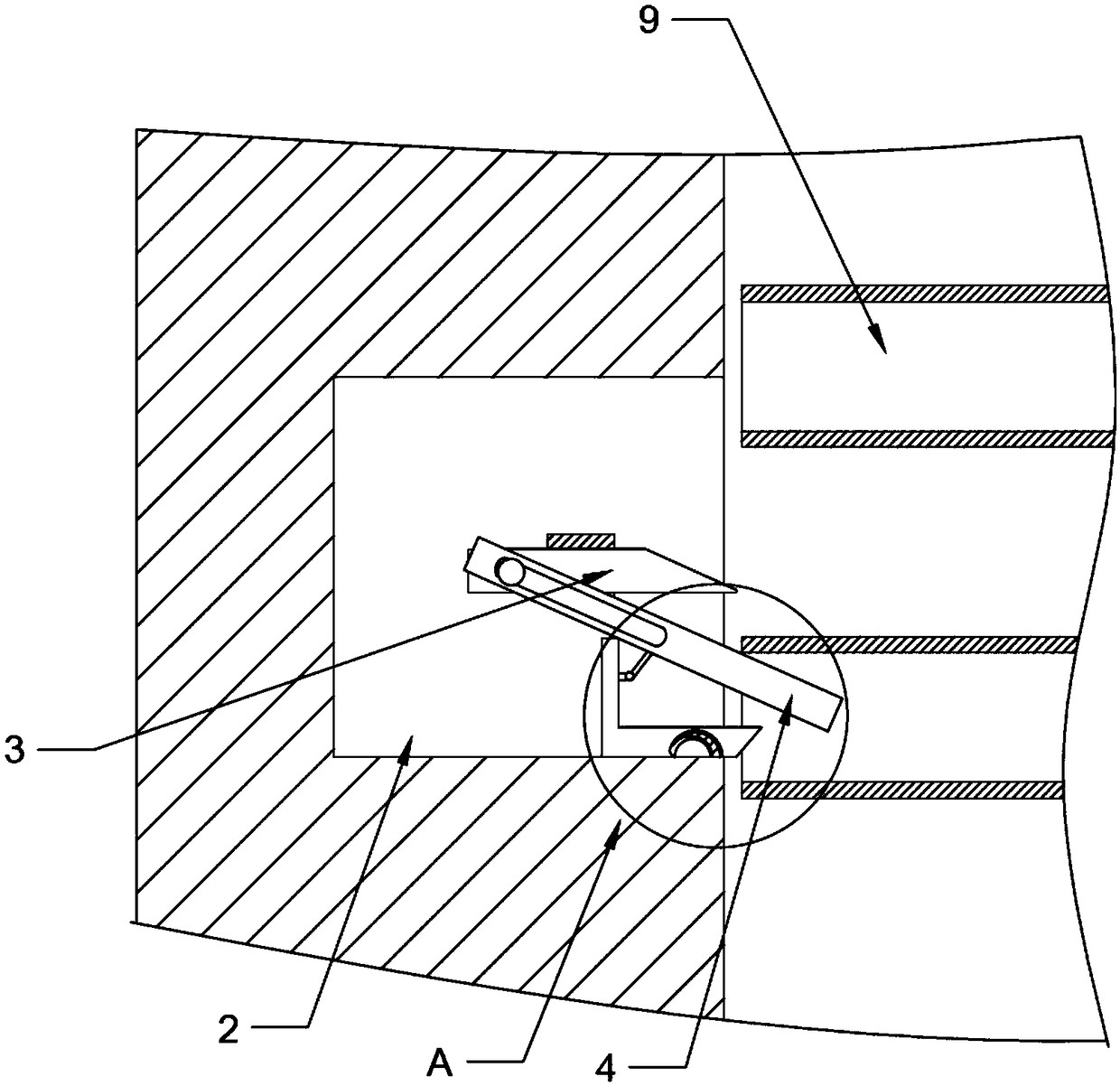

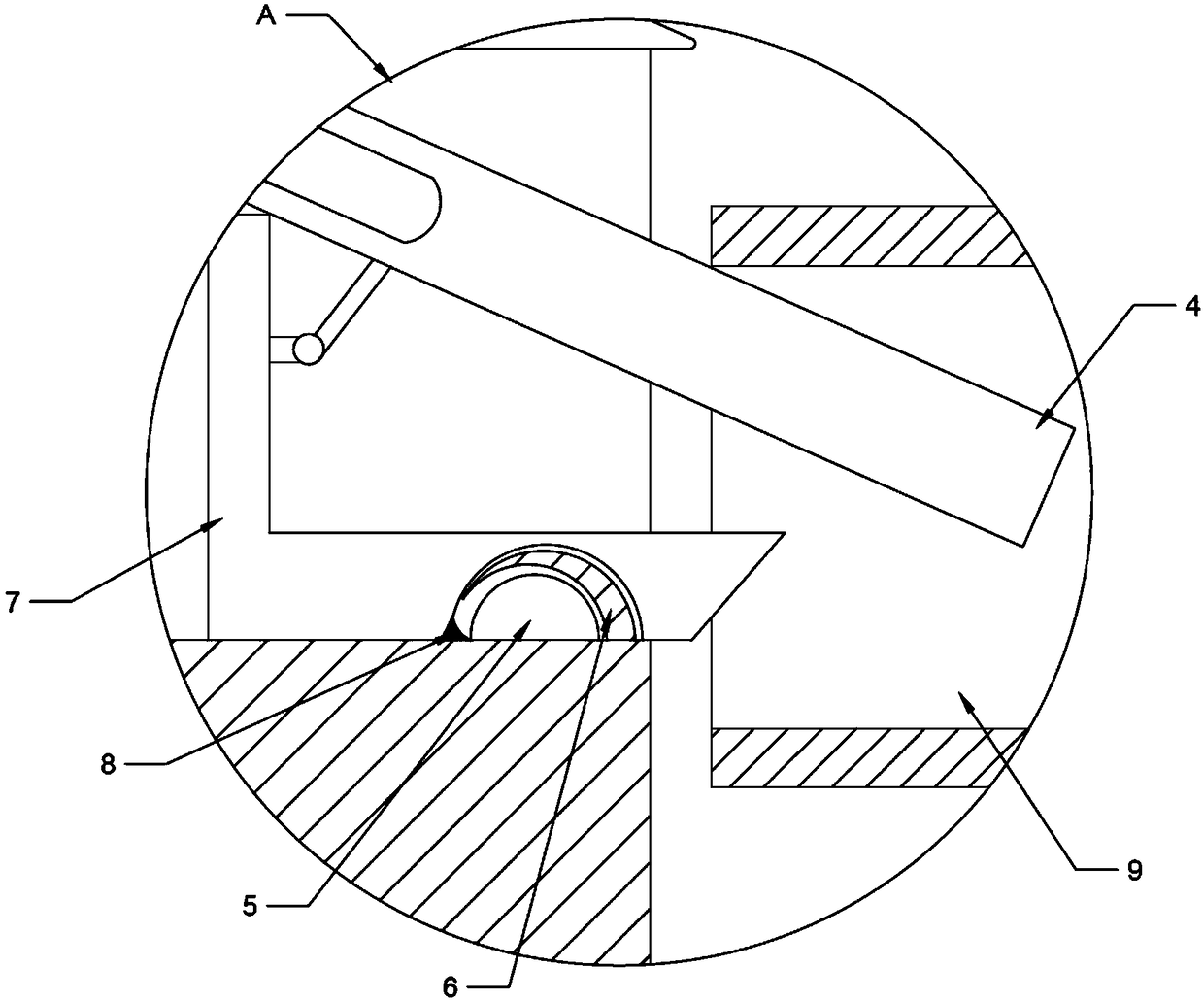

[0015] The reference numerals in the accompanying drawings of the specification include: channel 1 , receiving groove 2 , wedge block 3 , connecting pipe 4 , contact switch 5 , arc-shaped cover 6 , starting plate 7 , driving plate 8 , and workpiece 9 .

[0016] The embodiment is basically as attached figure 1 As shown: the cleaning device for tubular workpieces includes a frame, and a channel 1 is opened in the vertical direction of the frame, and the width of the channel 1 is slightly larger than the length of the pipe fittings. Both left and right inner sidewalls of channel 1 are horizontally provided with accommodating groove 2, and a cleaning mechanism is installed in the accommodating groove 2. The horizontal positions of the two cleaning mechanisms are staggered. During the process, it is convenient for the timely discharge of sewage, avoiding the accumulation of sewage in the pipe fitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com