Robot pick-and-place device

A technology of picking and unloading, manipulator, applied in the field of manipulator, can solve the problems of long steel pipe processing cycle, low work efficiency, cumbersome process, etc., and achieve the effect of simplifying process, reducing cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

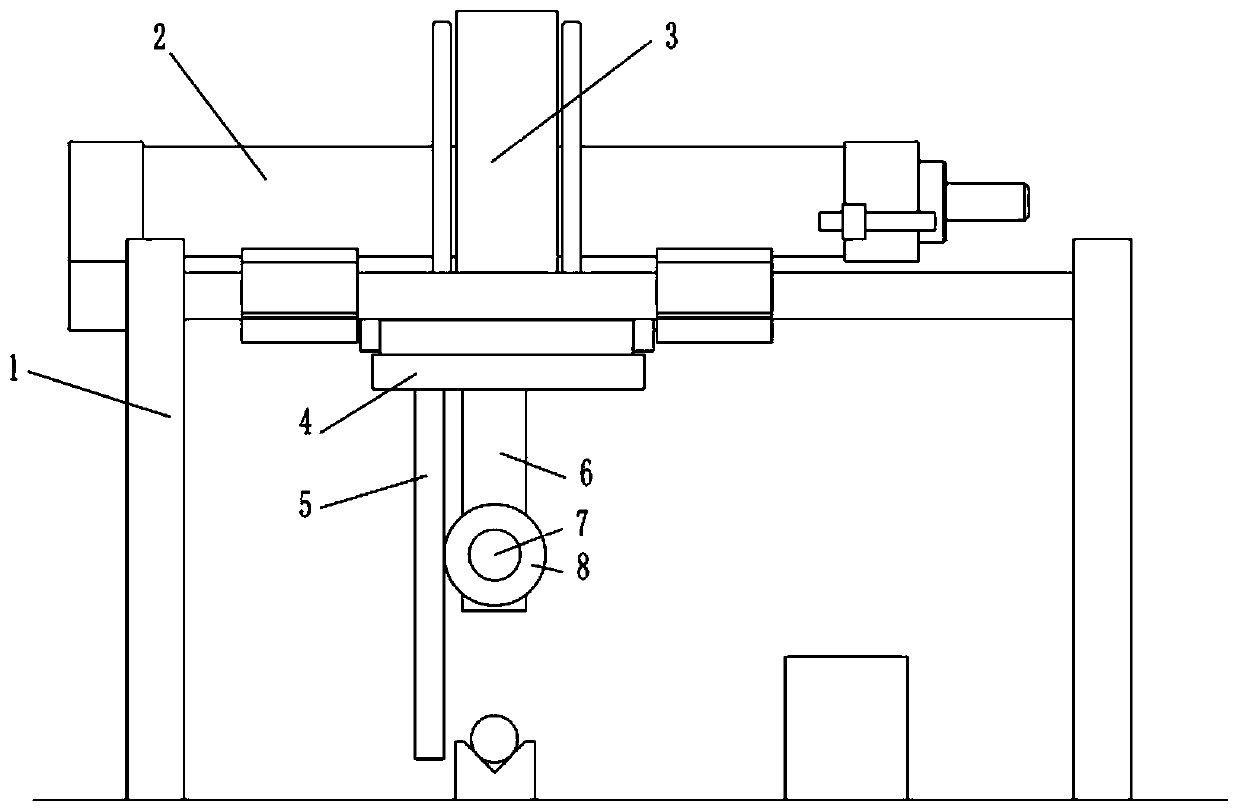

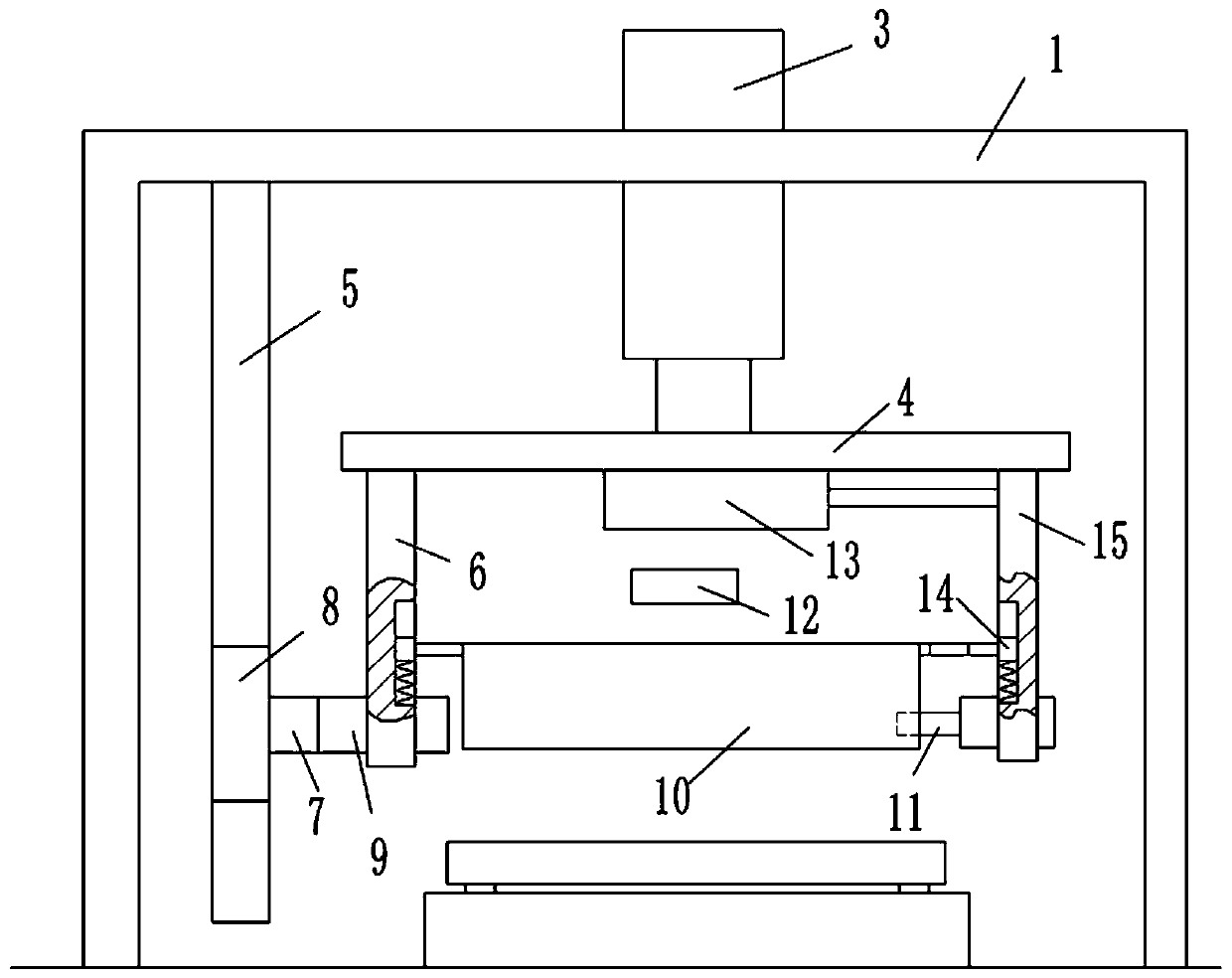

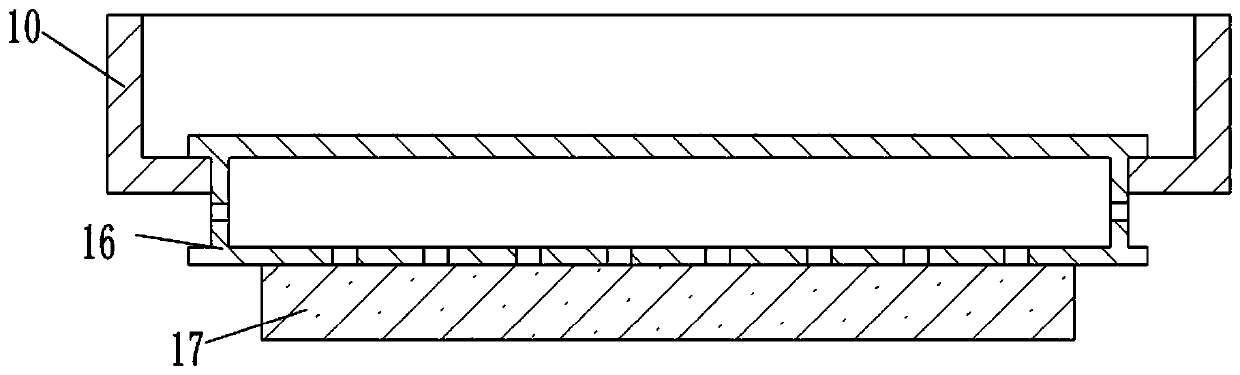

[0017] Description of reference signs: frame 1, push cylinder 2, lift cylinder 3, support plate 4, rack 5, first clamping arm 6, rotating shaft 7, gear 8, clamping hand 9, rust removal cover 10, air expansion Shaft 11, block 12, horizontal cylinder 13, slide block 14, second clamping arm 15, slide block 16, sponge 17, rust removal brush 18.

[0018] Such as figure 1 , figure 2 As shown, a manipulator pick-and-place device includes a frame 1, and the frame 1 is provided with a horizontal pushing mechanism. The horizontal pushing mechanism includes two guide rails parallel to each other, the guide rails are fixedly connected on the frame 1, and the guide rails are slidably connected with supporting plates. The left end of the frame 1 is fixedly connected with a push cylinder 2, and the piston rod of the push cylinder 2 is fixedly connected with the supporting plate. Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap