Mechanical arm provided with two-degree-of-freedom connecting rod mechanism and used for transporting operation

A technology of link mechanism and degree of freedom, applied in the mechanical field, can solve problems such as high precision requirements, low transmission efficiency, complex structure, etc., and achieve the effect of overcoming high precision requirements, good dynamic performance, and low inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

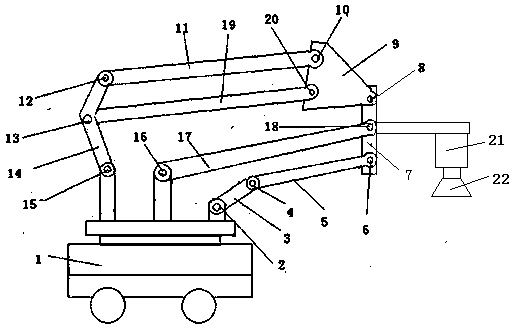

[0006] A mechanical arm with a two-degree-of-freedom link mechanism for handling operations, including a base 1, a large arm 17, a first active rod 3, a first connecting rod 5, a wrist connecting rod 7, a second active rod 14, and a second connecting rod 19. The third connecting rod 11, connecting block 9, wrist 21, vacuum suction cup 22, driving device; one end of the big arm 17 is connected to the base 1 through the first rotating pair 16, and the other end is connected to the wrist through the second rotating pair 18. One end of the first active rod 3 is connected to the base 1 through the third rotating pair 2, the other end is connected to the first connecting rod 5 through the fourth rotating pair 4, and the first connecting rod 5 is connected to the fifth rotating pair 6 It is connected with the wrist link 7; one end of the second active rod 14 is connected with the base 1 through the sixth rotating pair 15, and the other end is connected with the second connecting rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com