Adjustable large-size steel pipe lifting appliance

An adjustable and large-scale technology, applied in the field of lifting heavy objects, to achieve the effect of easy disassembly and replacement, simple structure and saving binding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

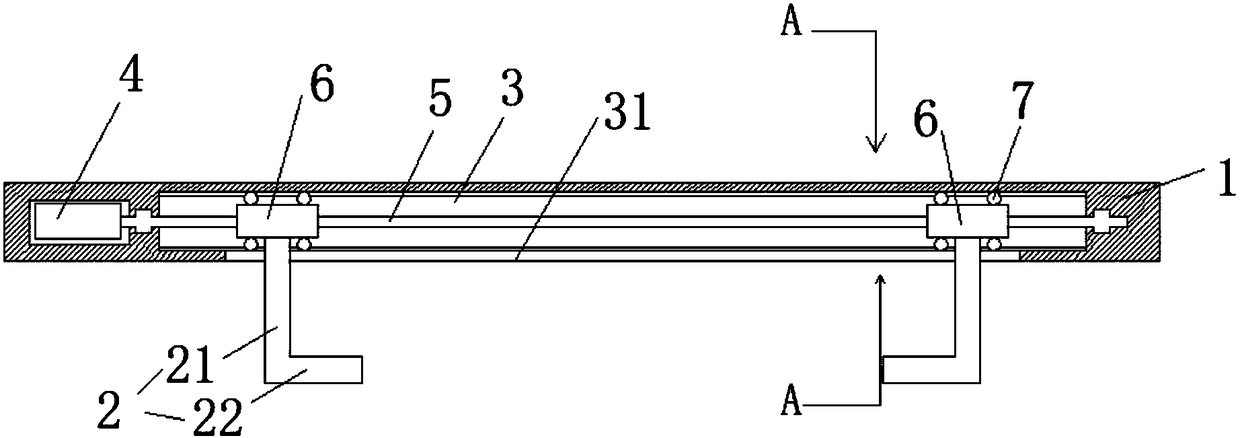

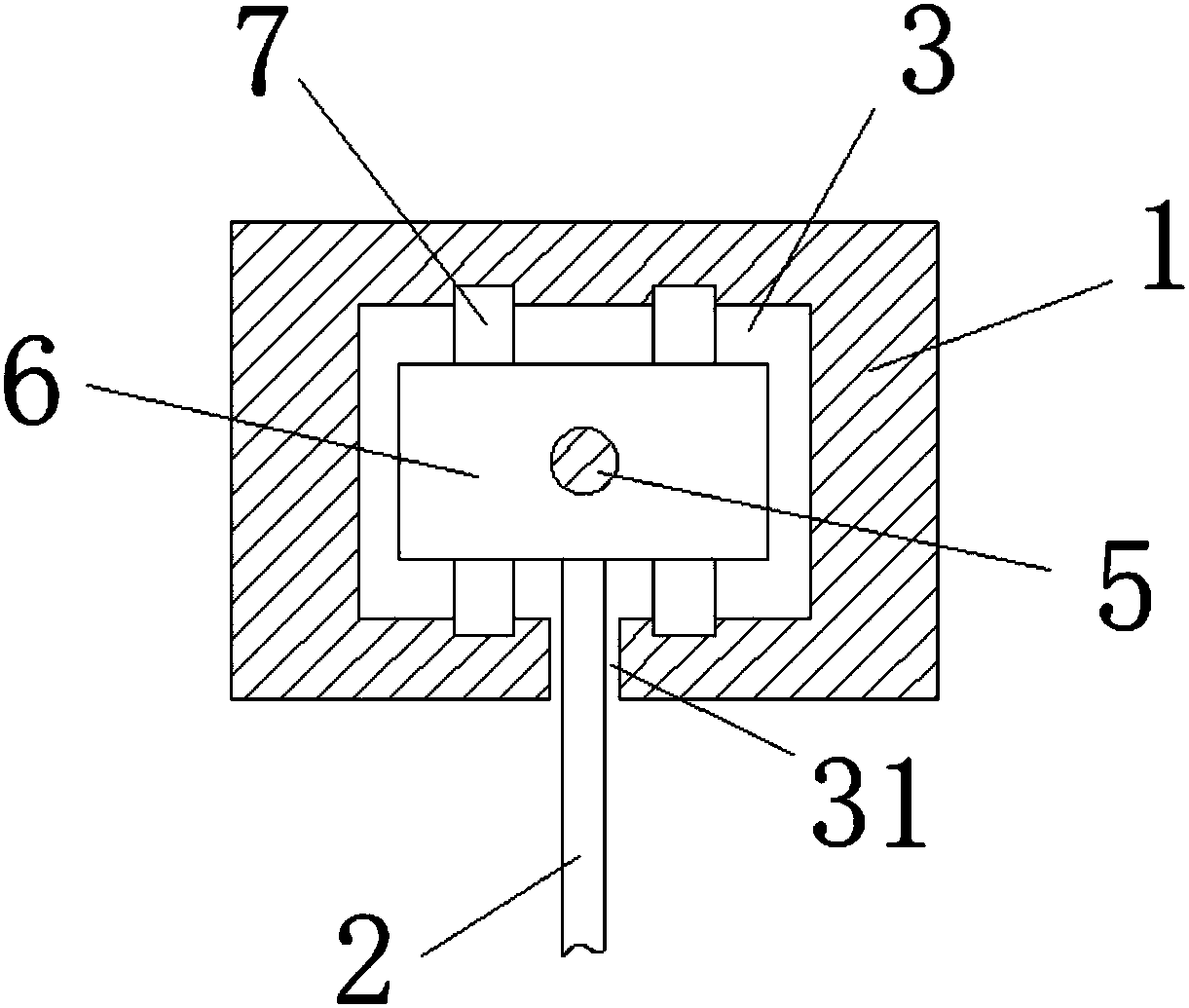

[0017] Such as Figure 1-2 As shown, an adjustable large-scale steel pipe hanger is composed of a hanging beam 1 and two hooks 2 mirrored at both ends of the hanging beam 1. The hanging hook 2 is composed of a vertical connecting part 21 and a The end of the connecting part 21 is composed of a hook part 22 perpendicular to the connecting part 21. The screw drive device is installed in the hanging beam 1, and the two connecting parts 21 of the suspension hook 2 are connected with the screw drive device. Under the control of the screw drive mechanism, it moves in the opposite direction or in the opposite direction.

[0018] During operation, the hoisting of steel pipes of different lengths is accomplished by controlling the motor to adjust the distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com