Building construction transport car

A technology for building construction and transport vehicles, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., which can solve the problems of time-consuming and labor-intensive, high labor intensity, and high-quality building materials, so as to improve handling efficiency, shorten binding time, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

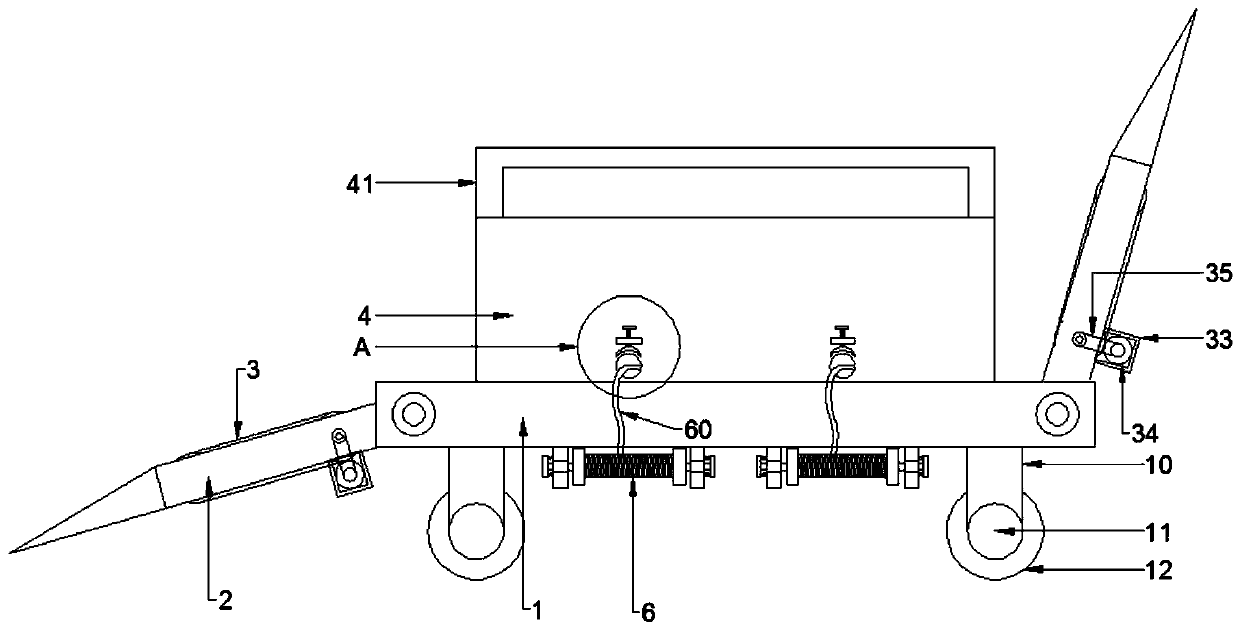

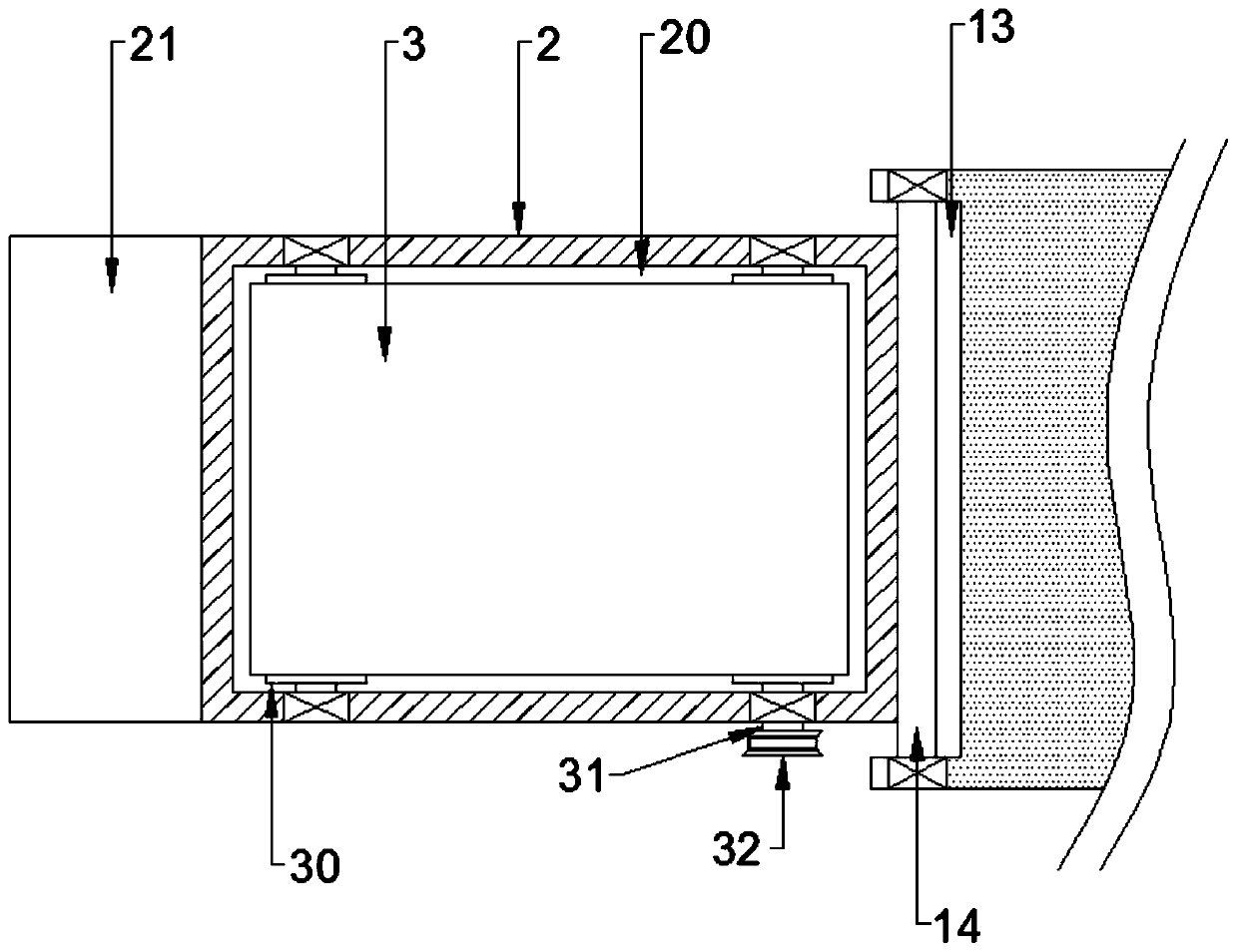

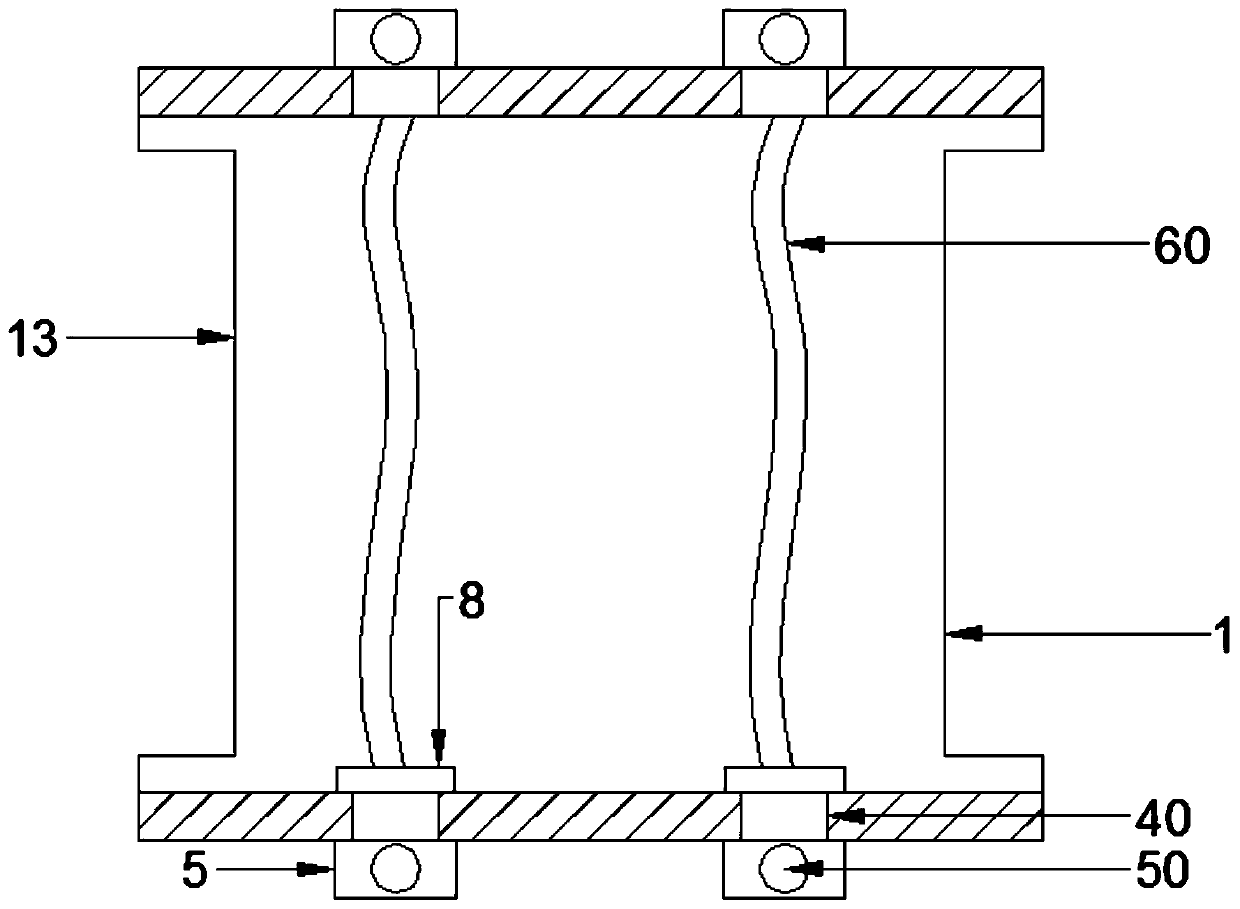

[0025] see Figure 1-6 , in an embodiment of the present invention, a construction truck includes a truck board 1, a transfer transfer board 2, a conveyor belt 3, a threading truck board 4, and a bobbin 6, and the two side walls of the truck board 1 are provided with There is a rotatable transfer transfer plate 2, the upper surface of the transfer transfer plate 2 is provided with a rotatable transfer belt 3, and the top front and rear positions of the vehicle transfer plate 1 are vertically fixed with two threading car plates 4, so The threading vehicle plate 4 is provided with a threading opening 40, and a plurality of bobbins 6 are suspended by rotation on the bottom surface of the trolley plate 1, and a hoisting wire harness 60 is wound on the bobbins 6, and the hoisting wire harness 60 is formed by The threading opening 40 penetrates into the top surface between the threading car plates 4 on the front and rear sides of the car transport plate 1;

[0026] A handrail frame...

Embodiment 2

[0032] The difference between this embodiment and embodiment 1 is:

[0033] The outer opening of the threading port 40 is provided with a crimping device, and the crimping device includes a screw plate 5, a crimping screw 50 and a crimping plate 51, and the screw plate 5 is fixed on the outer panel of the threading car plate 4 , the screw plate 5 is located directly above the threading port 40, the screw plate 5 is provided with a 52, and the internal thread of the 52 is passed through the crimping screw 50, and the bottom end of the crimping screw 50 is fixed to the crimping plate 51. The crimping plate 51 is an arc-shaped rubber block, and the crimping plate 51 can adjust the vertical height by rotating the crimping screw 50, so as to clamp the hoisting wire harness 60 passing through the threading port 40;

[0034] The rear end opening of the threading port 40 is provided with a thread trimmer, and the thread trimmer is installed on the inner wall of the threading car plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com