Hydraulic lining and rail train

A technology for hydraulic bushings and rail trains, applied in the directions of shafts and bearings, transportation and packaging, railway car body parts, etc., can solve the problems of wheel and rail wear, increase the operating cost of trains, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

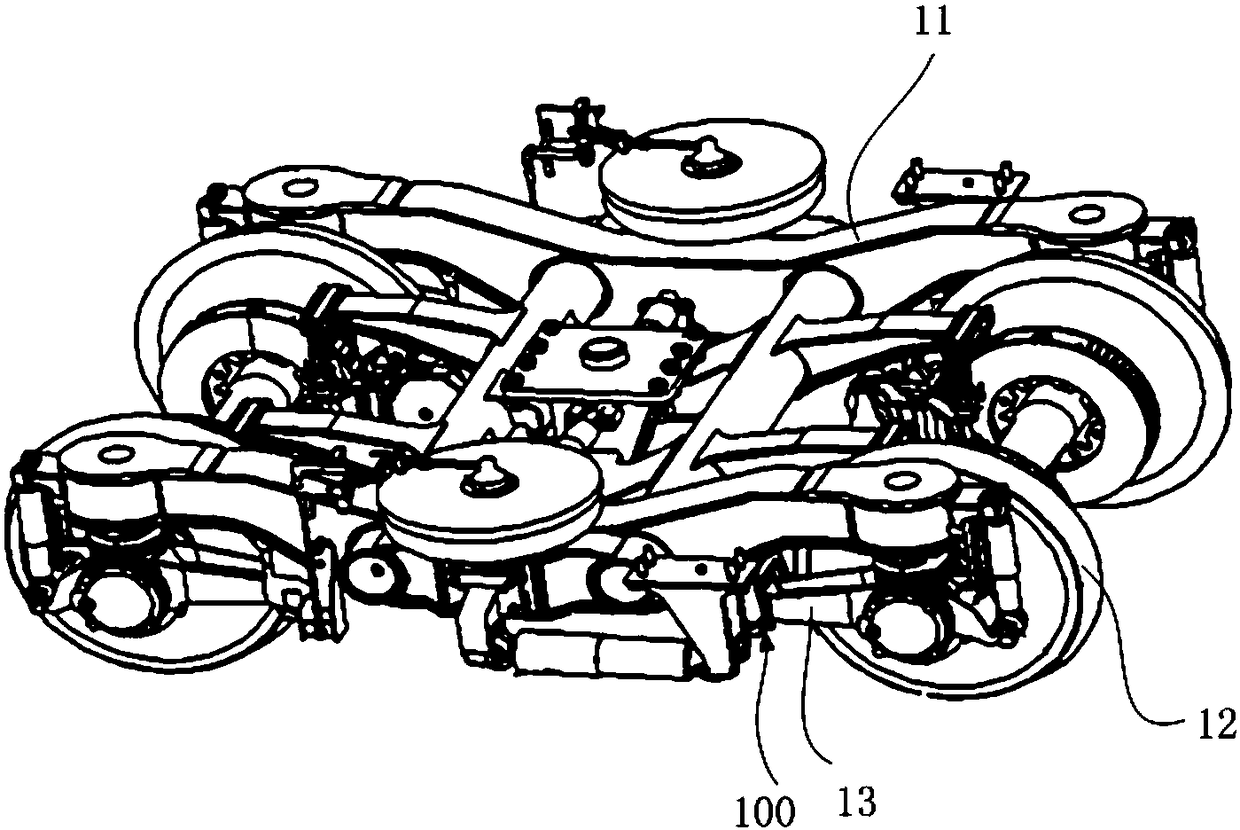

[0041] figure 1 An installation position 100 of a hydraulic bush 1 in a rail train according to an embodiment of the present invention is schematically shown. Such as figure 1As shown, the rail car includes a bogie 11 and wheels 12 . The wheel 12 includes a positioning arm 13 . The hydraulic bushing 1 is connected with the bogie 11 and the wheel 12 at the same time. See the description below for the specific connection method. During the straight running of the rail train, the hydraulic bushing 1 has greater rigidity to help the train move forward stably; Steering is smooth, reducing wear on the wheels 12 and rails.

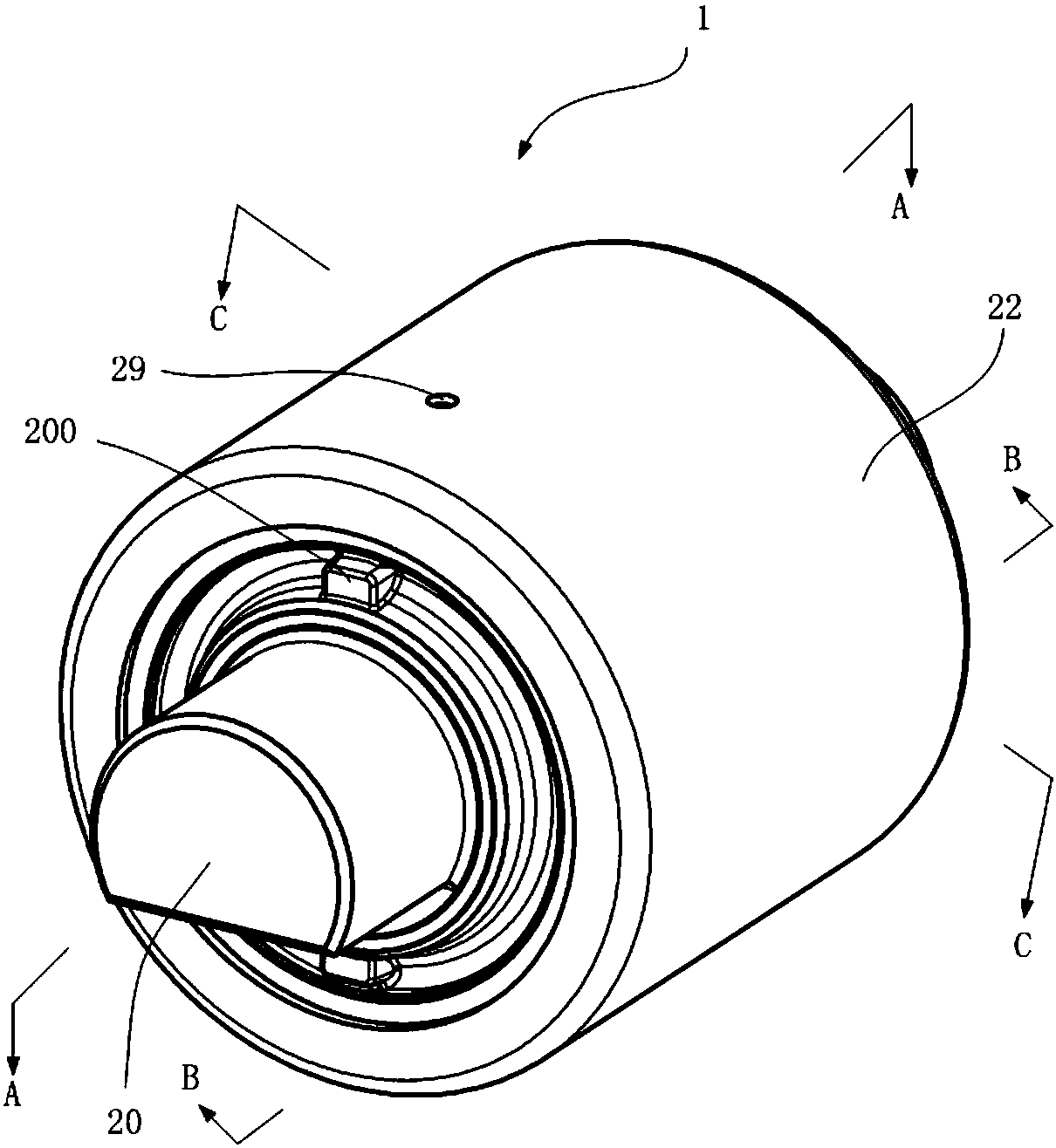

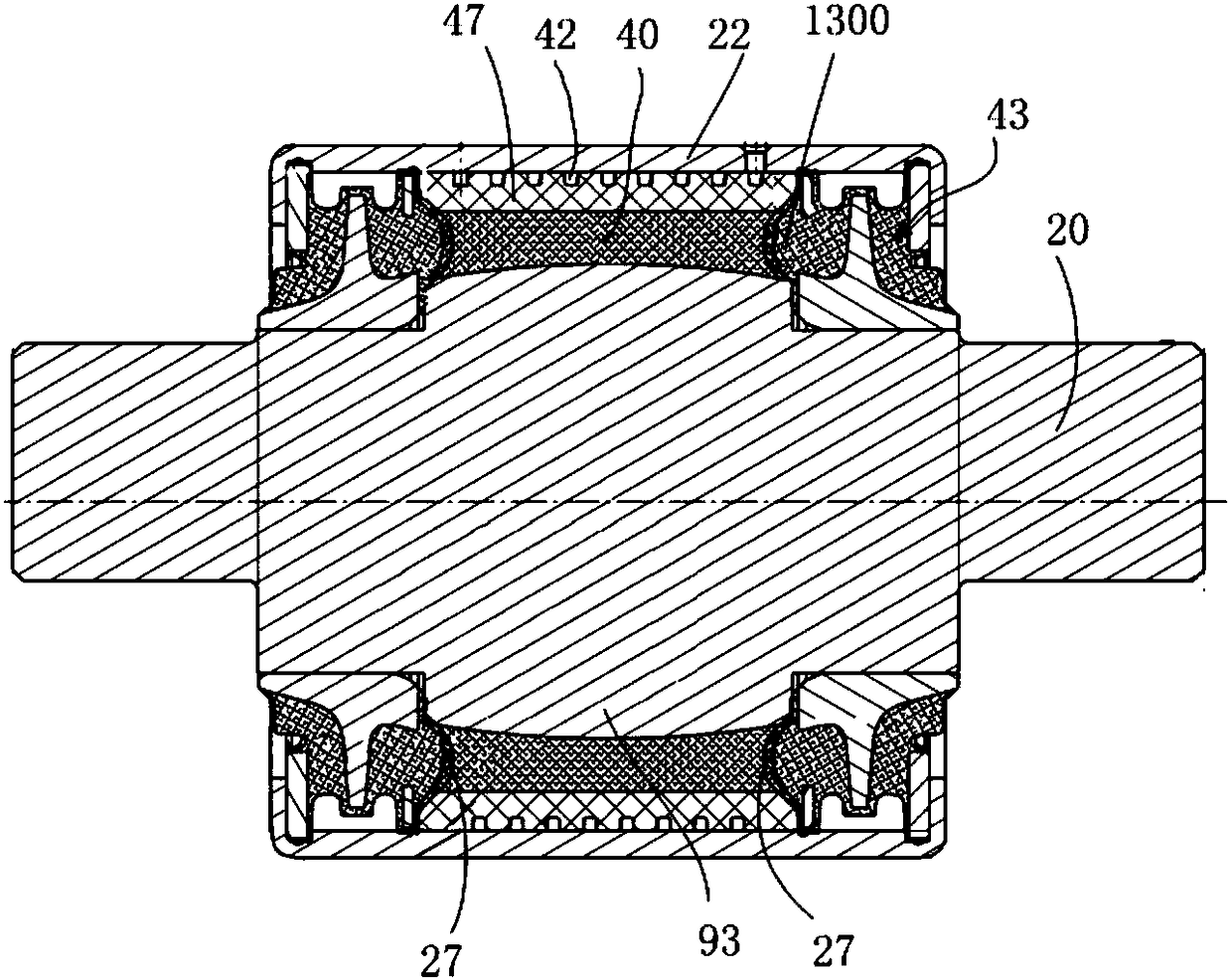

[0042] figure 2 , 3 , 4 and 5 show an embodiment of the hydraulic bushing 1 . Such as Figure 2-5 As shown, the hydraulic bushing 1 includes a mandrel 20 , a sleeve 47 sleeved on the outside of the mandrel 20 , and an outer sleeve 22 sleeved on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com