An automatic discharging device and a feeding device

An automatic feeding device and feeding trough technology, which is applied in the field of breeding tools, can solve the problems of unable to achieve daily quantitative feeding, unable to achieve soaked feed feeding, unable to achieve divided meal feeding, etc., and achieve the realization of feed soaking feeding. , the labor intensity of workers is reduced, and the effect of eliminating waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

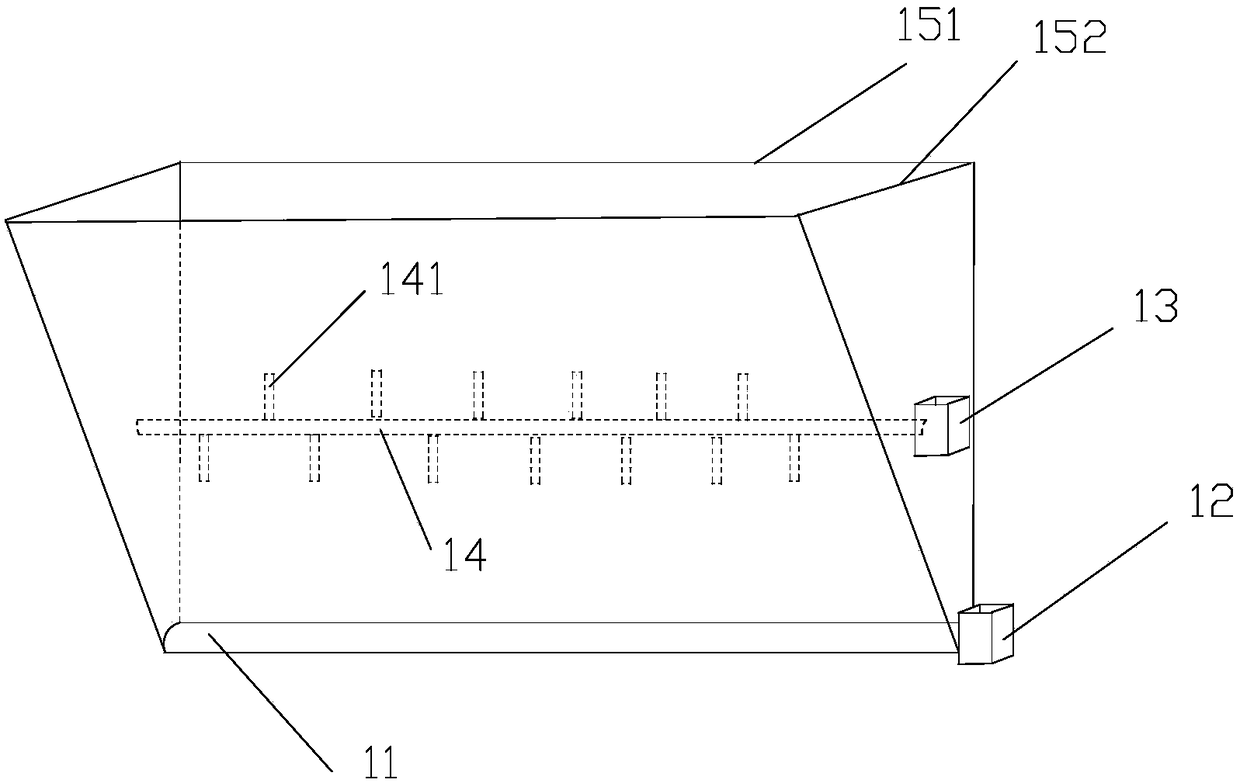

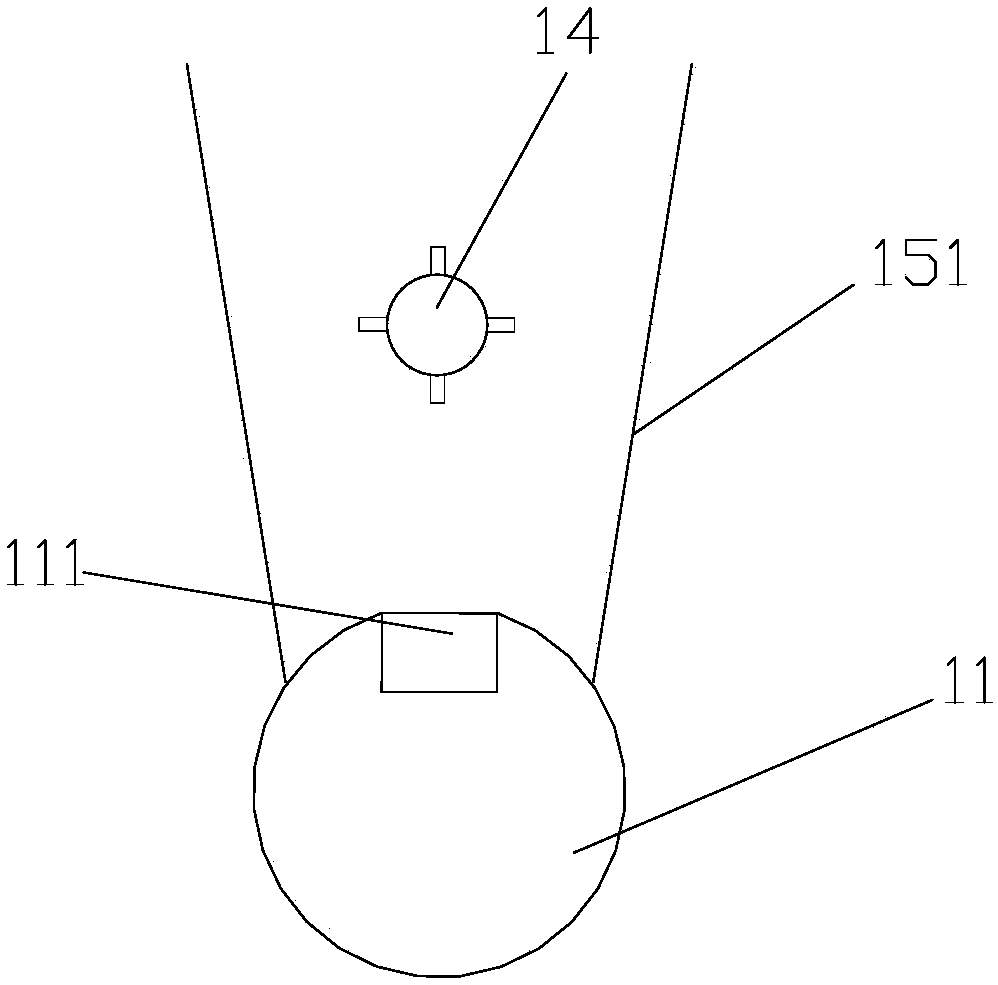

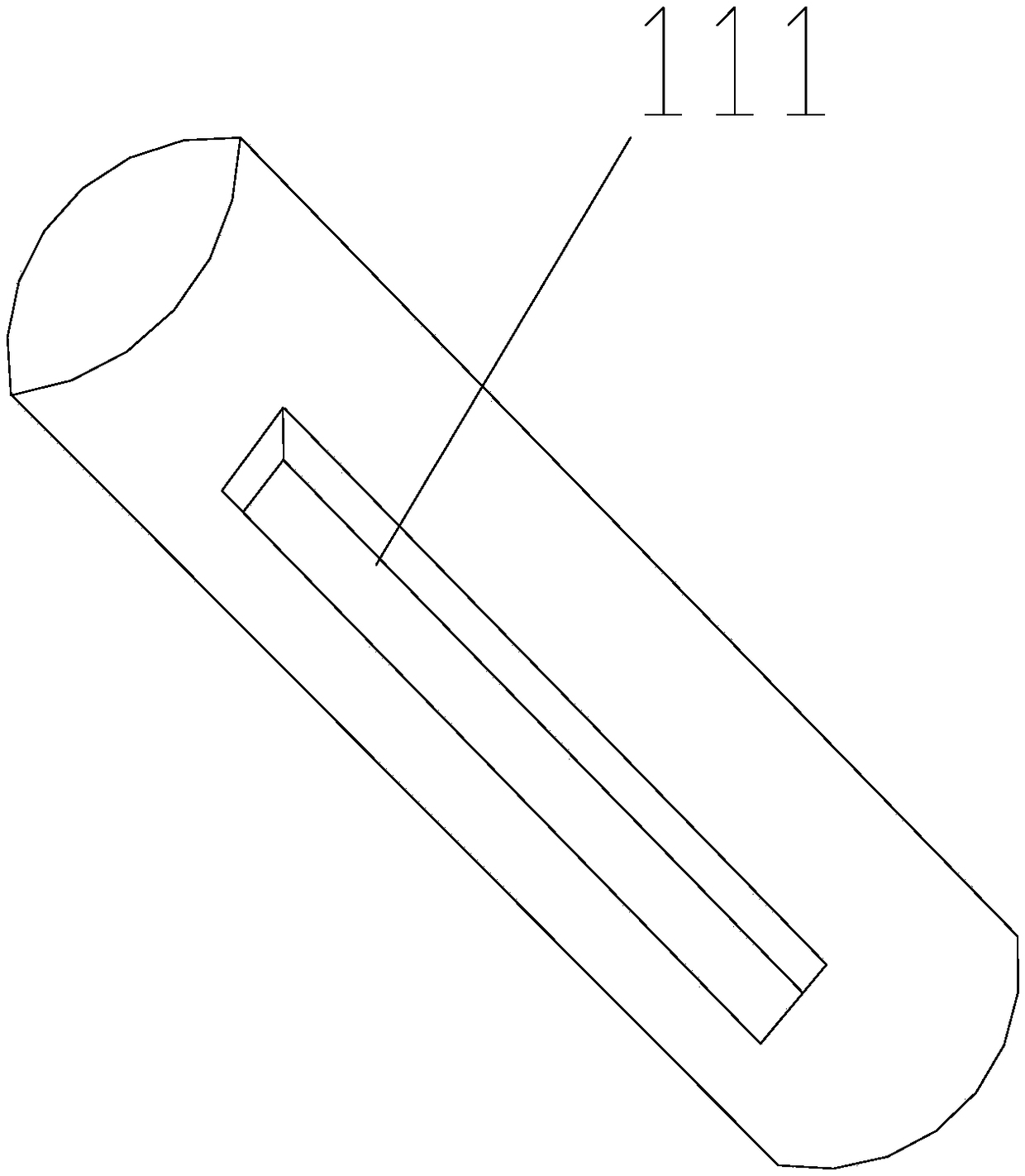

[0030] as attached figure 1 , attached figure 2 and attached image 3 As shown, a kind of automatic discharge device comprises storage bin 15, round roller 11 and motor 12, and the bottom of storage bin 15 has discharge port, and round roller 11 is installed in rotary seal at the discharge port, and round roller 11 side The wall has a storage tank 111; the motor 12 is installed outside the storage bin 15, and the motor 12 is used to drive the round roller 11 to rotate.

[0031] Feed is stored in the storage bin 15. When the storage tank 111 of the round roller 11 is located in the storage bin 15, the feed will fill the storage tank 111. When the storage tank 111 rotates to the outside of the storage bin 15, the storage The feed on the trough 111 will gradually fall out to the feeding trough, and when the feed trough 111 is fully turned to point directly downward, the feed in the trough 111 will completely fall out, and a discharge process has been completed so far. When th...

Embodiment 2

[0040] as attached figure 1 , attached figure 2 and attached image 3 As shown, a kind of automatic discharge device comprises storage bin 15, round roller 11 and motor 12, and the bottom of storage bin 15 has discharge port, and round roller 11 is installed in rotary seal at the discharge port, and round roller 11 side The wall has a storage tank 111; the motor 12 is installed outside the storage bin 15, and the motor 12 is used to drive the round roller 11 to rotate.

[0041] Feed is stored in the storage bin 15. When the storage tank 111 of the round roller 11 is located in the storage bin 15, the feed will fill the storage tank 111. When the storage tank 111 rotates to the outside of the storage bin 15, the storage The feed on the trough 111 will gradually fall out. When the feed trough 111 is fully turned to point directly below, the feed in the trough 111 will completely fall out. So far, a discharge process has been completed. When the round roller 11 Continue to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com