A kind of preparation method of aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and electrolytic paper, which is applied in the field of capacitors, can solve the problems of constant use and difficult to see the contents of the sleeve, and achieve the effects of improving yield, reducing impedance, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

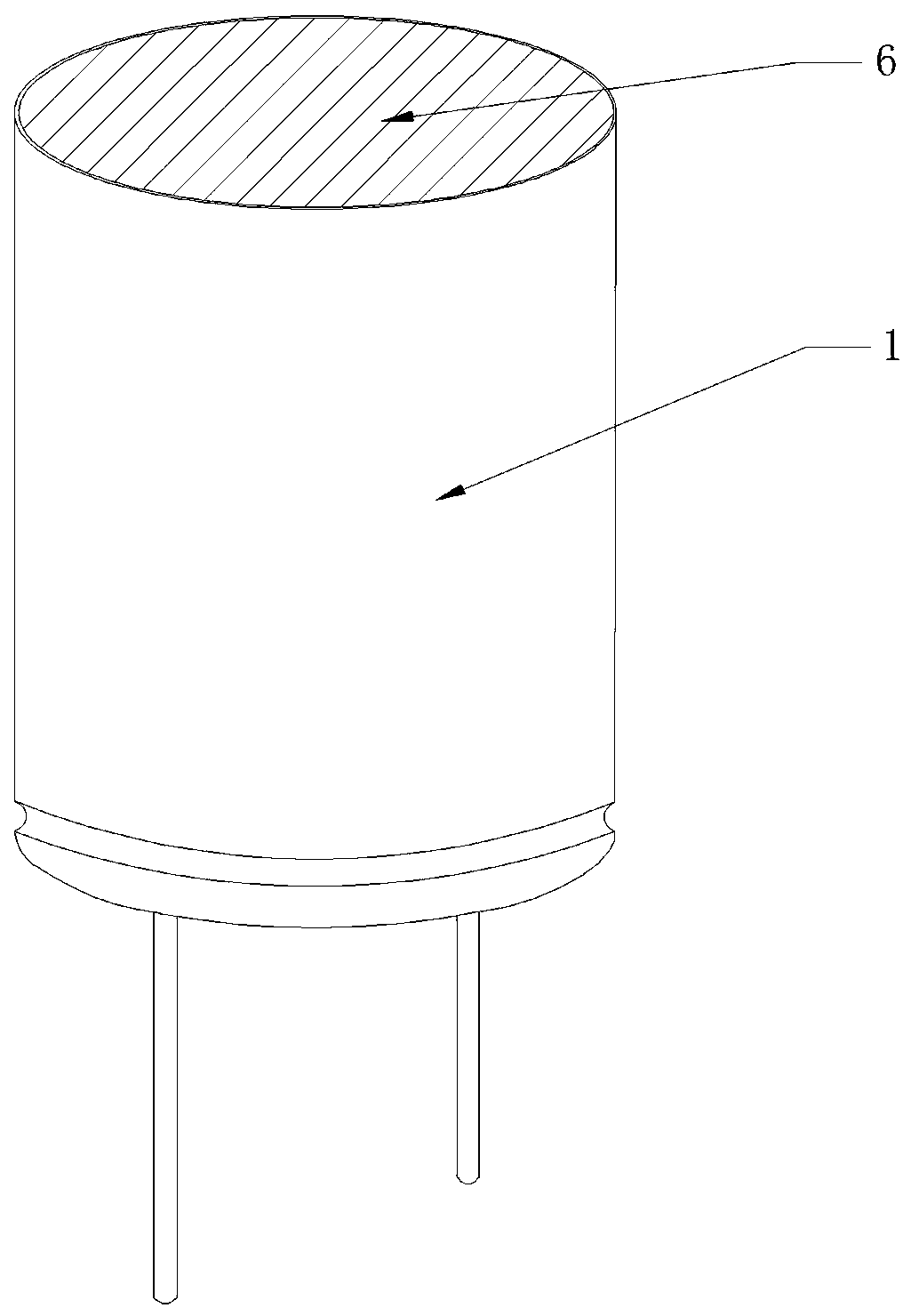

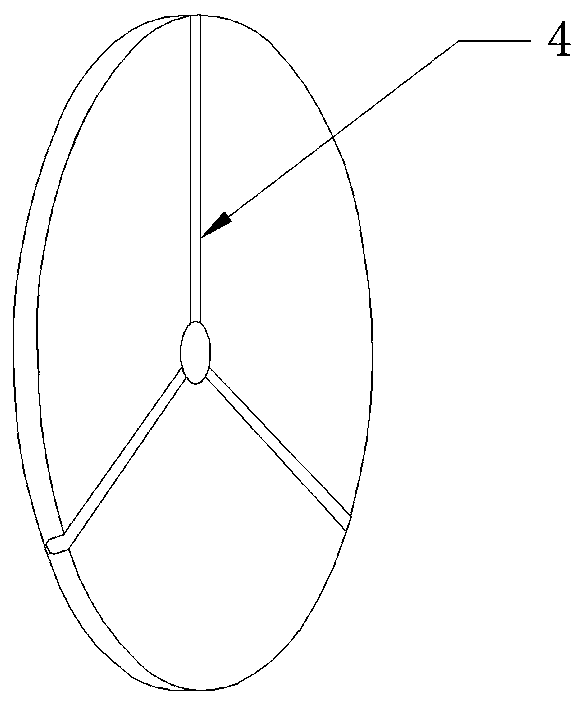

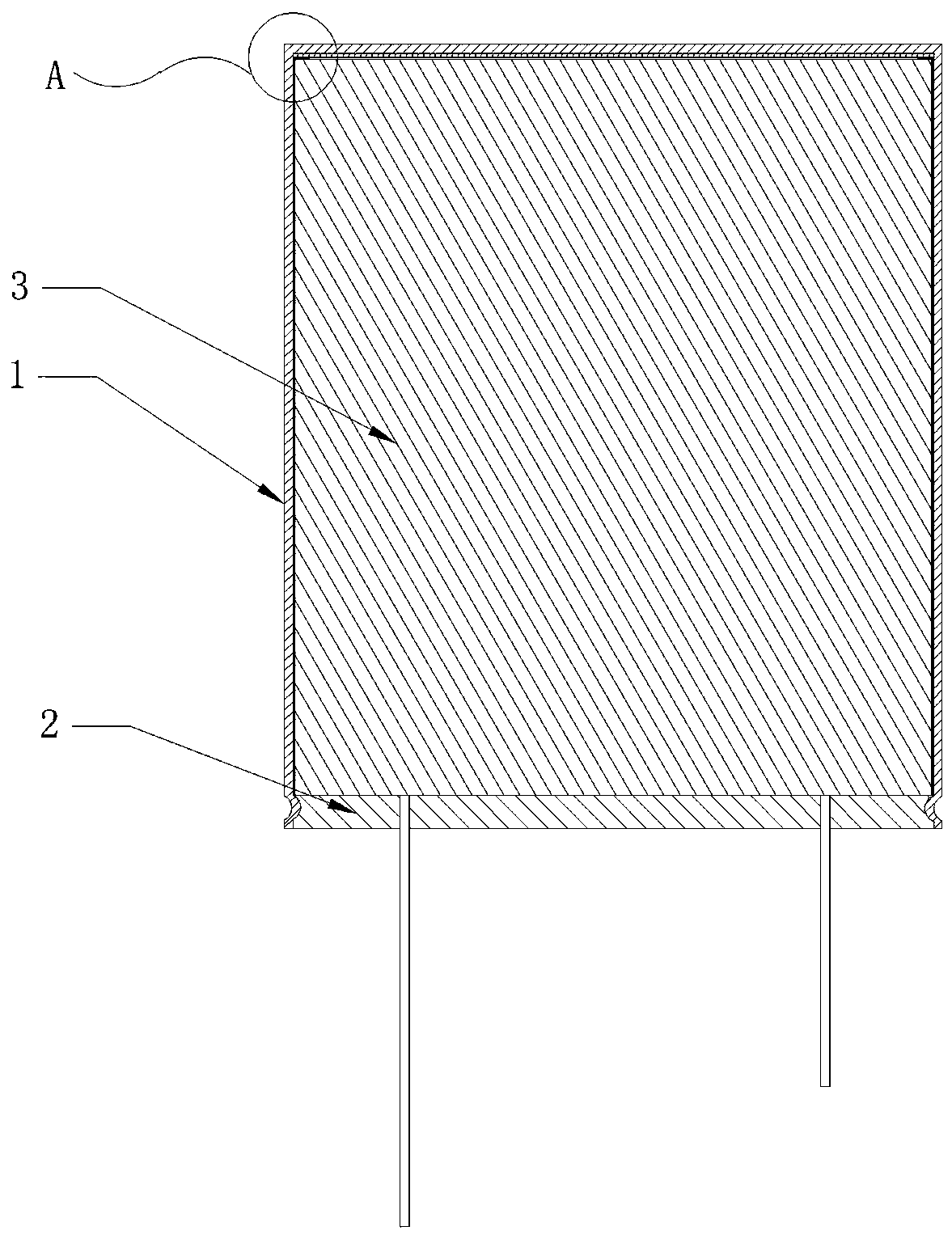

[0037] An aluminum electrolytic capacitor, comprising a shell 1, a rubber plug 2 and a core pack 3, the rubber plug 2 seals the core pack 3 impregnated with electrolyte in the shell 1, and the inner shell surface at the bottom of the shell 1 is provided with an explosion-proof groove 4. The explosion-proof groove 4 is facing the bottom of the core package 3, and a layer of pad paper 5 is arranged between the bottom of the core package 3 and the explosion-proof groove 4;

[0038] In this embodiment, two layers of scotch tape 7 are wrapped around the outside of the core pack 3 , and the scotch tape 7 protrudes 1 mm from the bottom of the core pack 3 . The core pack 3 is formed by winding the positive electrode foil 8, the electrolytic paper 10 and the negative electrode foil 9. 0.8mm on both sides.

[0039]The preparation method of the aluminum electrolytic capacitor of the present invention includes the following steps, 1) cutting, cutting the positive electrode foil, negative...

Embodiment 2

[0059] In this embodiment, the core package 3 is formed by winding the positive electrode foil 8, the electrolytic paper 10 and the negative electrode foil 9; the width of the positive electrode foil 8 is 2 mm wider than the negative electrode foil 9, and both sides of the positive electrode foil 8 protrude from the negative electrode foil by 1 mm. Both sides of the electrolytic paper 10 protrude from both sides of the positive electrode foil 8 by 1 mm.

[0060] Other parts of this embodiment are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com