Display assembly and assembling method thereof

An assembly method and display technology, which can be applied to static indicators, parts and instruments of electrical measuring instruments, etc., can solve problems such as damage to the quality of display components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

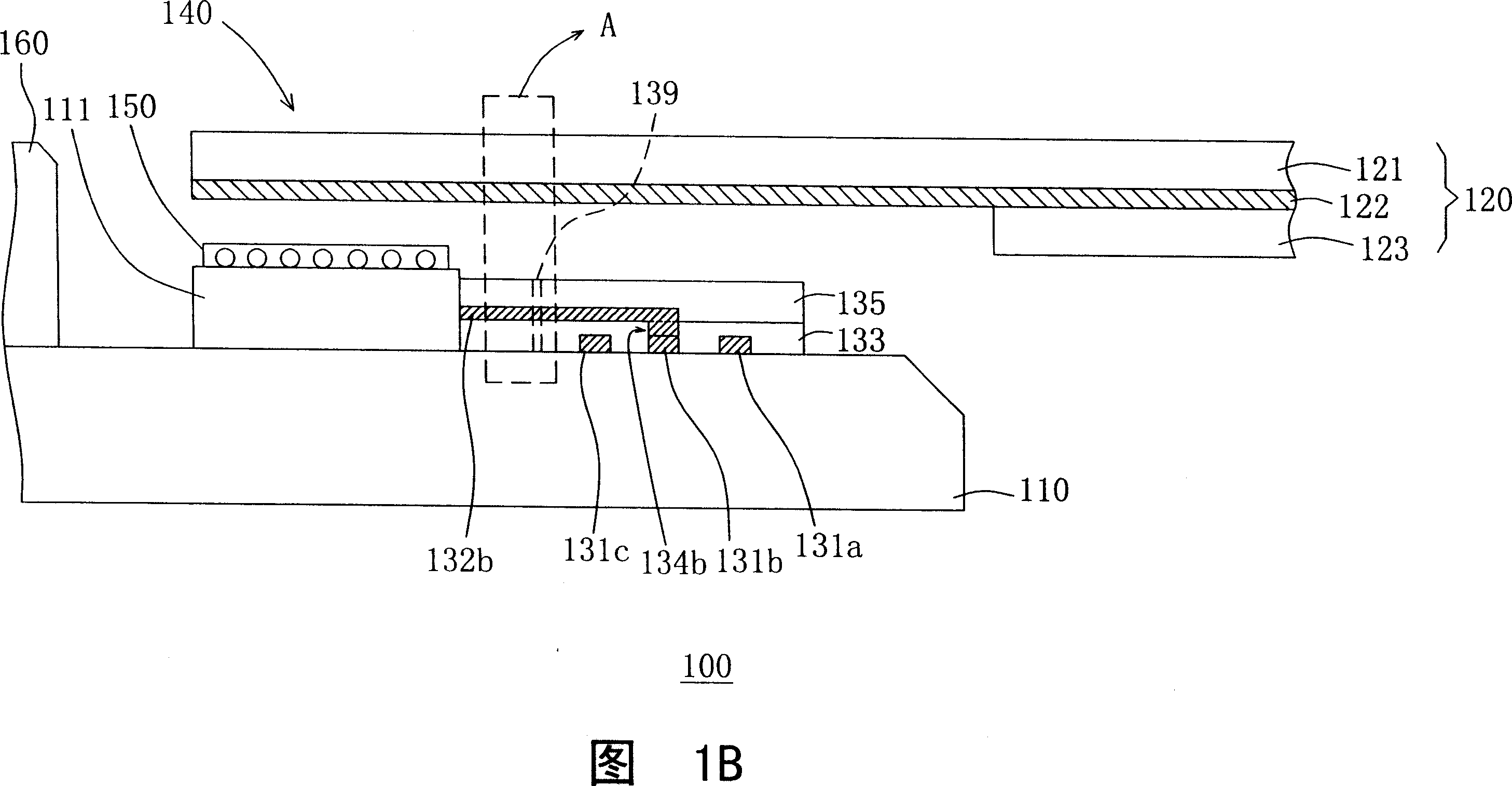

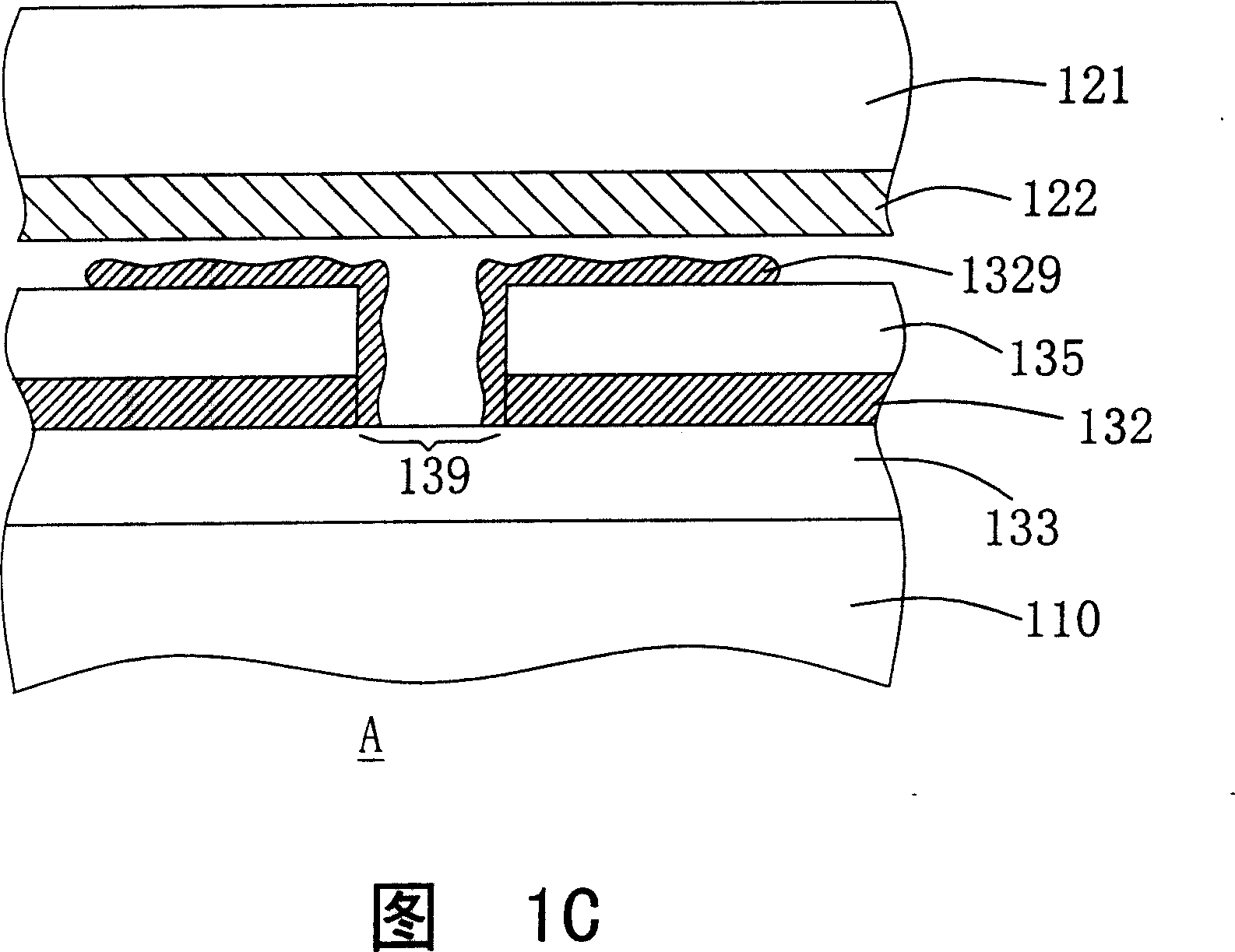

[0018] Please refer to FIG. 2 , which is a cross-sectional view of a display unit according to a preferred embodiment of the present invention. In FIG. 2 , the display assembly 200 includes a glass substrate 210 , a tape carrier package (TCP) 220 and a protective insulating layer 290 . The display component 200 is, for example, a liquid crystal display component, and the glass substrate 210 is, for example, a glass substrate of a TFT substrate.

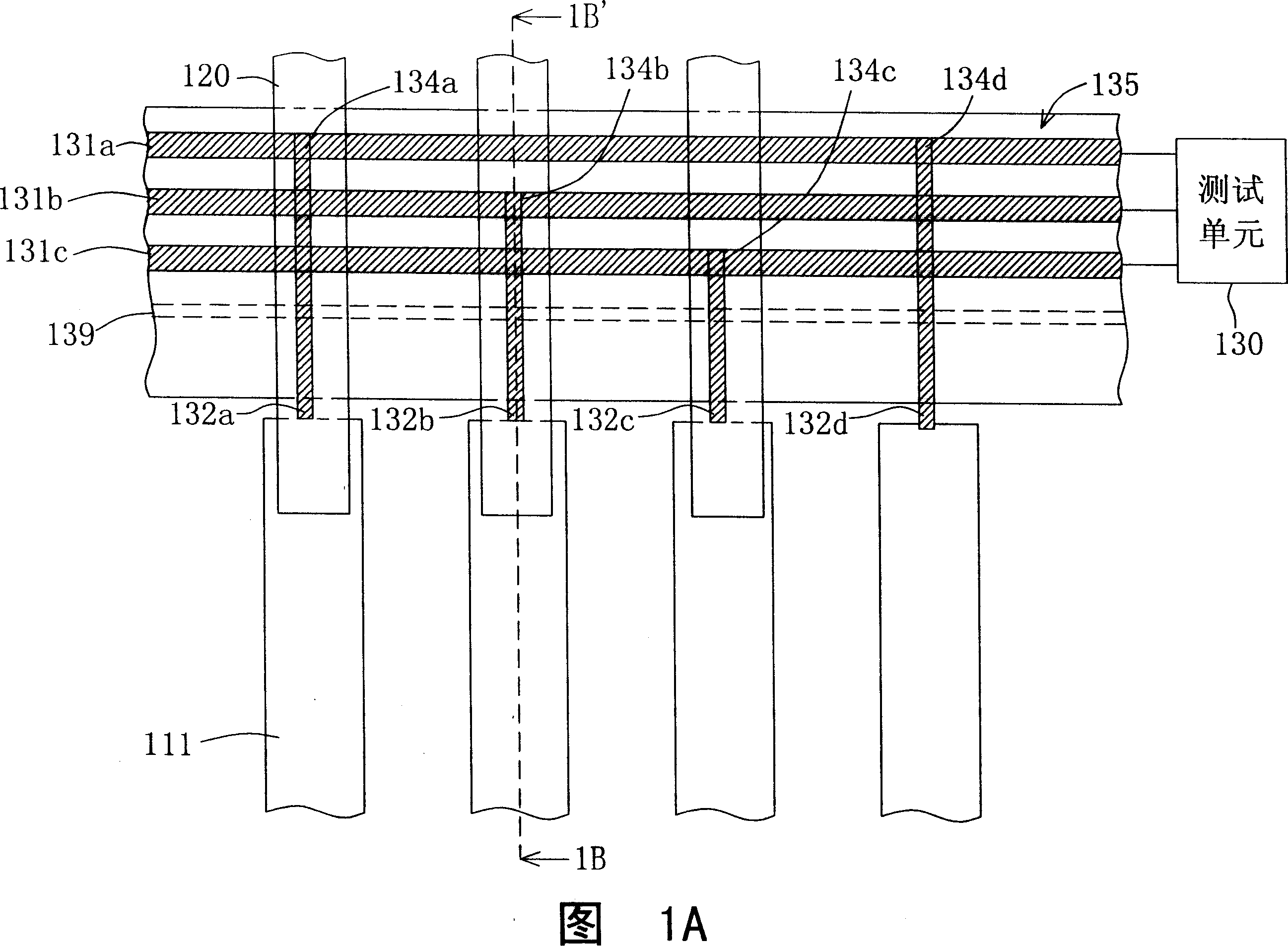

[0019] The glass substrate 210 has a display area 260, a plurality of indium tin oxide (Indium Tin Oxide, ITO) pins 211, and is equipped with a plurality of shorting bars, such as wires 231a, 231b, and 231c, and a plurality of wires. , only the wire 232b is used for illustration in FIG. 2 .

[0020] An insulating layer (Passivation Layer, PL) 233 is covered on the wires 231a, 231b and 231c. The wiring 232 b is located on the insulating layer 233 , and the wiring 232 b is covered with an insulating layer 235 which is also on the insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com