Battery system with thermal management

A battery system and heat management technology, applied in secondary batteries, circuits, electrical components, etc., to achieve the effect of reducing liquid leakage and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Before explaining the present invention, if it is considered that related descriptions of well-known structures or functions may unnecessarily obscure the gist of the present invention, the detailed description thereof will be omitted.

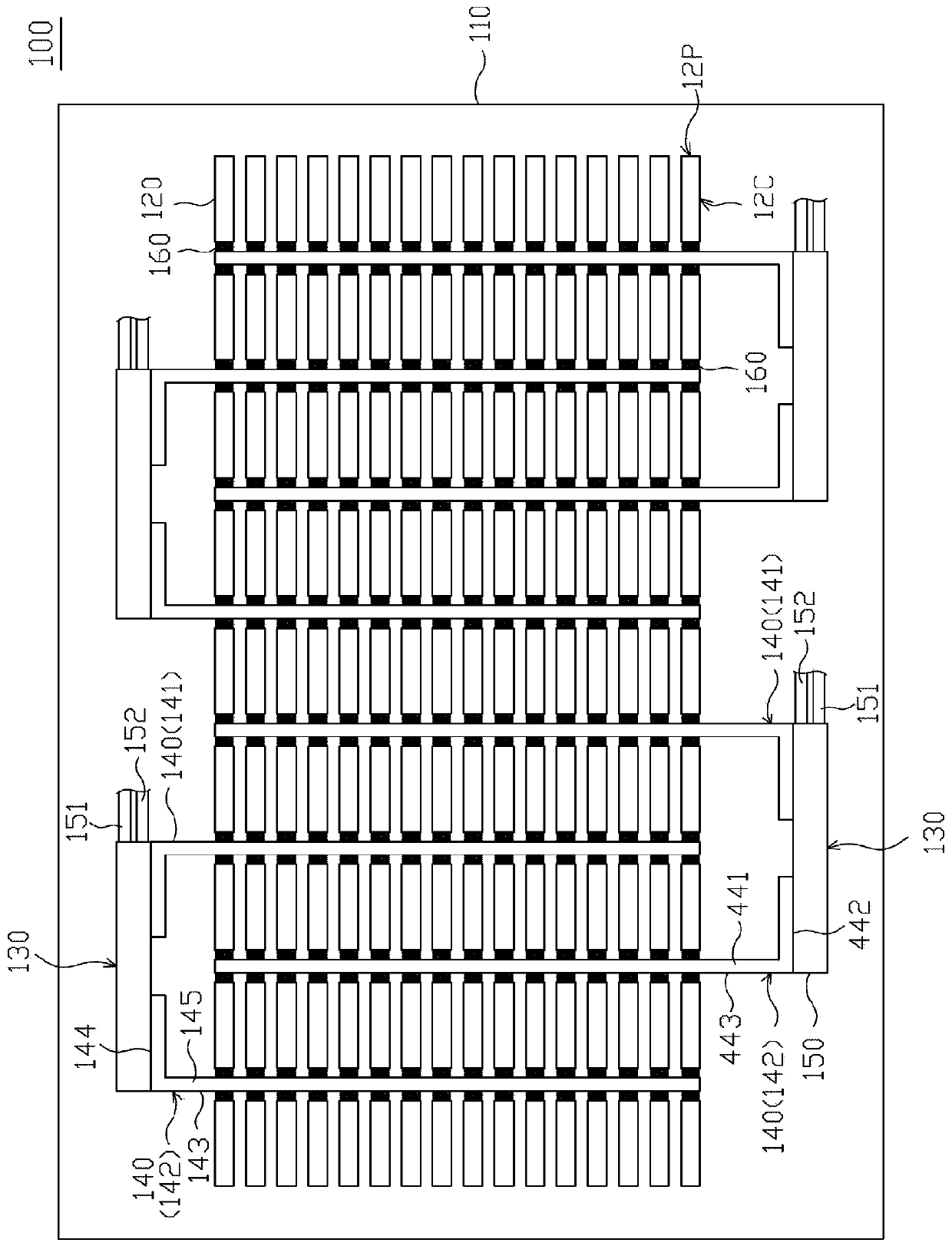

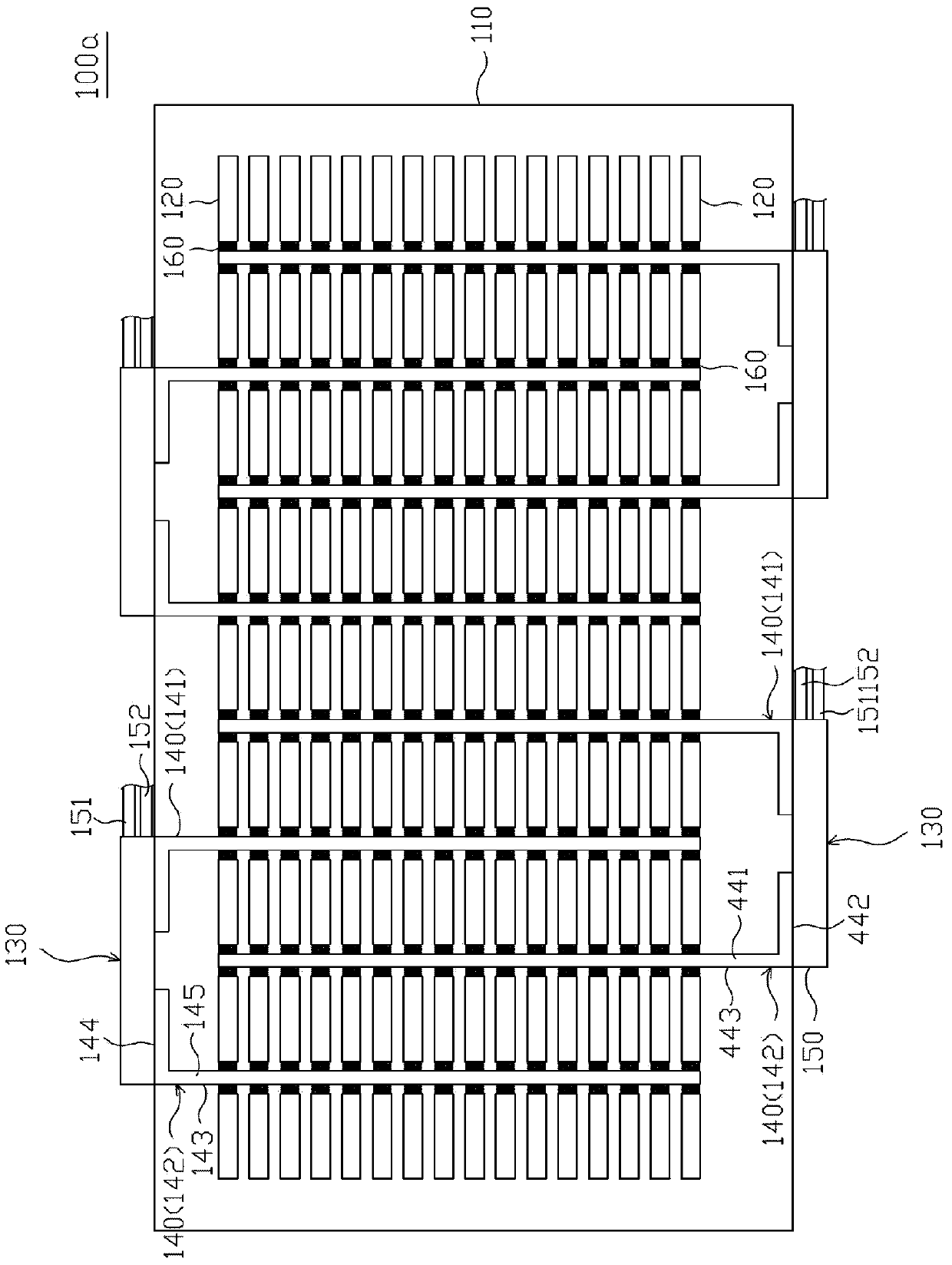

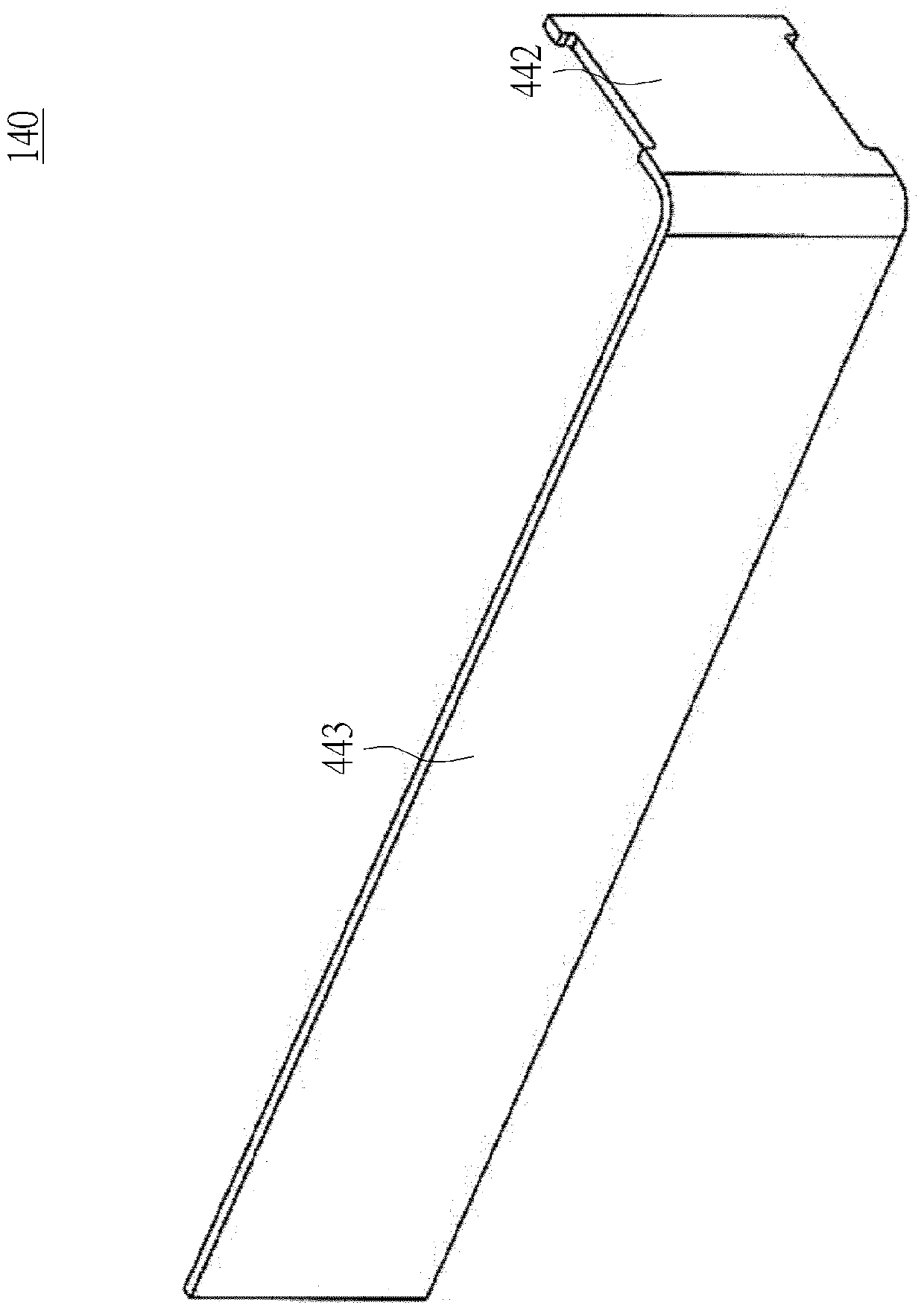

[0057] figure 1 A schematic diagram showing a battery system with thermal management function according to an embodiment of the present invention. Such as figure 1 As shown, the battery system 100 with thermal management function includes a casing 110 , a plurality of battery cells 120 , and at least one regulating unit 130 capable of regulating the surface temperature of the battery cells 120 . The regulating unit 130 and the plurality of battery cells 120 are placed in the casing 110, and the plurality of battery cells 120 are in thermal contact with the regulating unit 130, so that heat can be conducted fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com