Method and device for crushing neodymium iron boron magnetic powder aggregate

A crushing device and crushing method technology, applied in non-rotational vibration suppression, grain processing, etc., can solve the problems of cumbersome crushing process and high labor intensity, and achieve the effect of reducing noise, reducing labor intensity, and high-efficiency crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

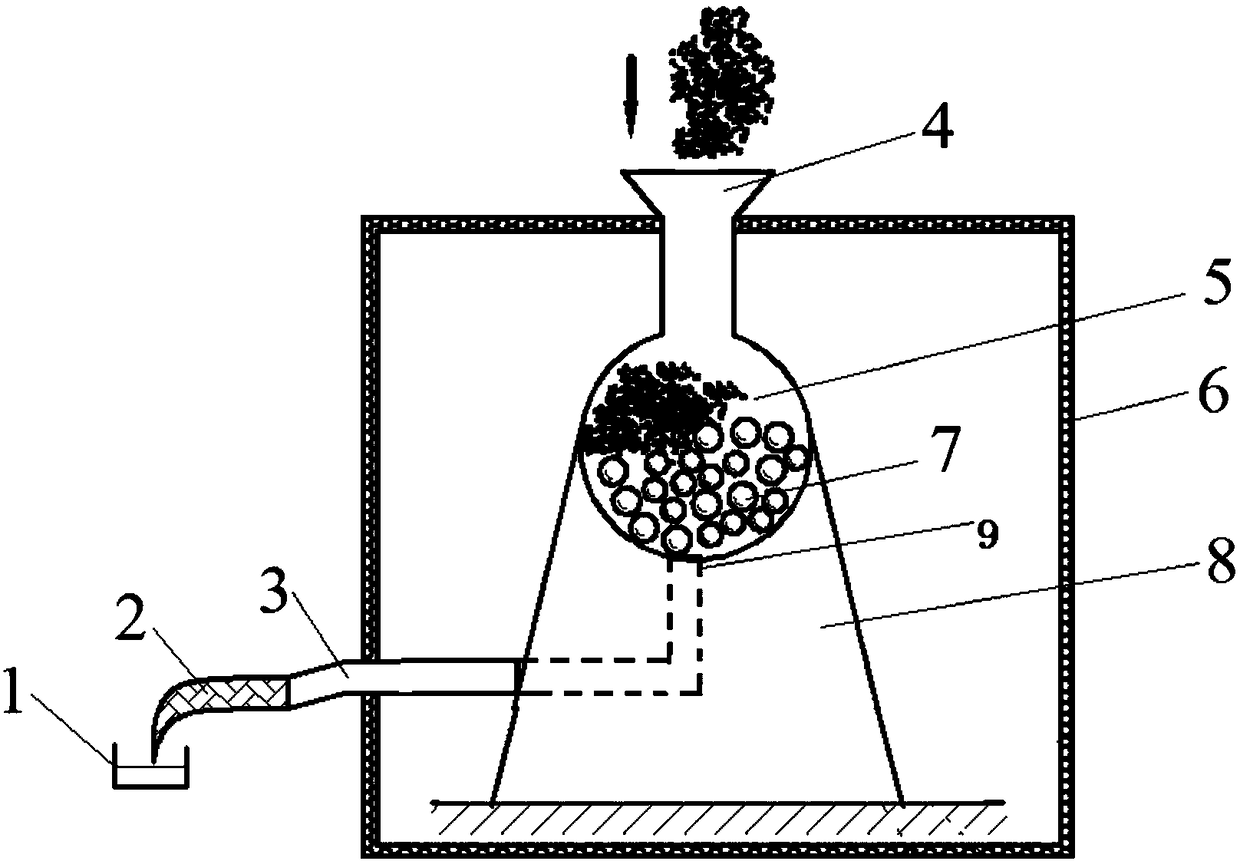

[0038] Such as figure 1 As shown, a crushing device of neodymium iron boron magnetic powder agglomerates of the present invention includes:

[0039] The vibrating mill mechanism 8 is provided with a vibrating cavity 5 containing a vibrating grinding medium 7 in the middle, a feed port 4 communicating with the vibrating cavity 5 is provided at the top, and a feeding port 4 connected to the vibrating cavity 5 is provided at the bottom end Through the discharge port 9;

[0040] The soundproof cover 6 is arranged outside the vibrating mill mechanism 8, and the side wall is provided with a discharge port 3 communicating with the discharge port 9;

[0041] The collecting part includes a bucket 1 and a flexible connection cloth bag 2 used to transfer materials from the discharge port 3 to the bucket 1.

[0042] As a preferred mode, the soundproof cover 6 is provided with a door.

[0043] Way of working:

[0044] When in use, after placing a suitable vibrating mill medium 7 in the vibrating cav...

Embodiment 2

[0052] This embodiment is improved on the basis of embodiment 1, and the filler ratio of the vibrating mill mechanism 8 is 0.6 to 0.8, preferably 0.7.

[0053] Preferably, the vibrating mill medium 7 includes 14 to 18 steel bars with a diameter of 15 mm and 5 to 9 steel bars with a diameter of 25 mm.

[0054] The operating parameters of the vibrating mill 8 with an amplitude of 9 mm and a frequency of 1200 r / min make the particle size of the powder after crushing concentrated between 100 mesh and 500 mesh, so as to meet the requirements for the magnetic powder particle size of the bonded NdFeB magnet pressing.

[0055] During operation, the feeding amount each time should not be too large, and should be less than 10% of the volume of the vibrating cavity of the vibrating mill mechanism to ensure that the vibrator has enough vibration space.

Embodiment 3

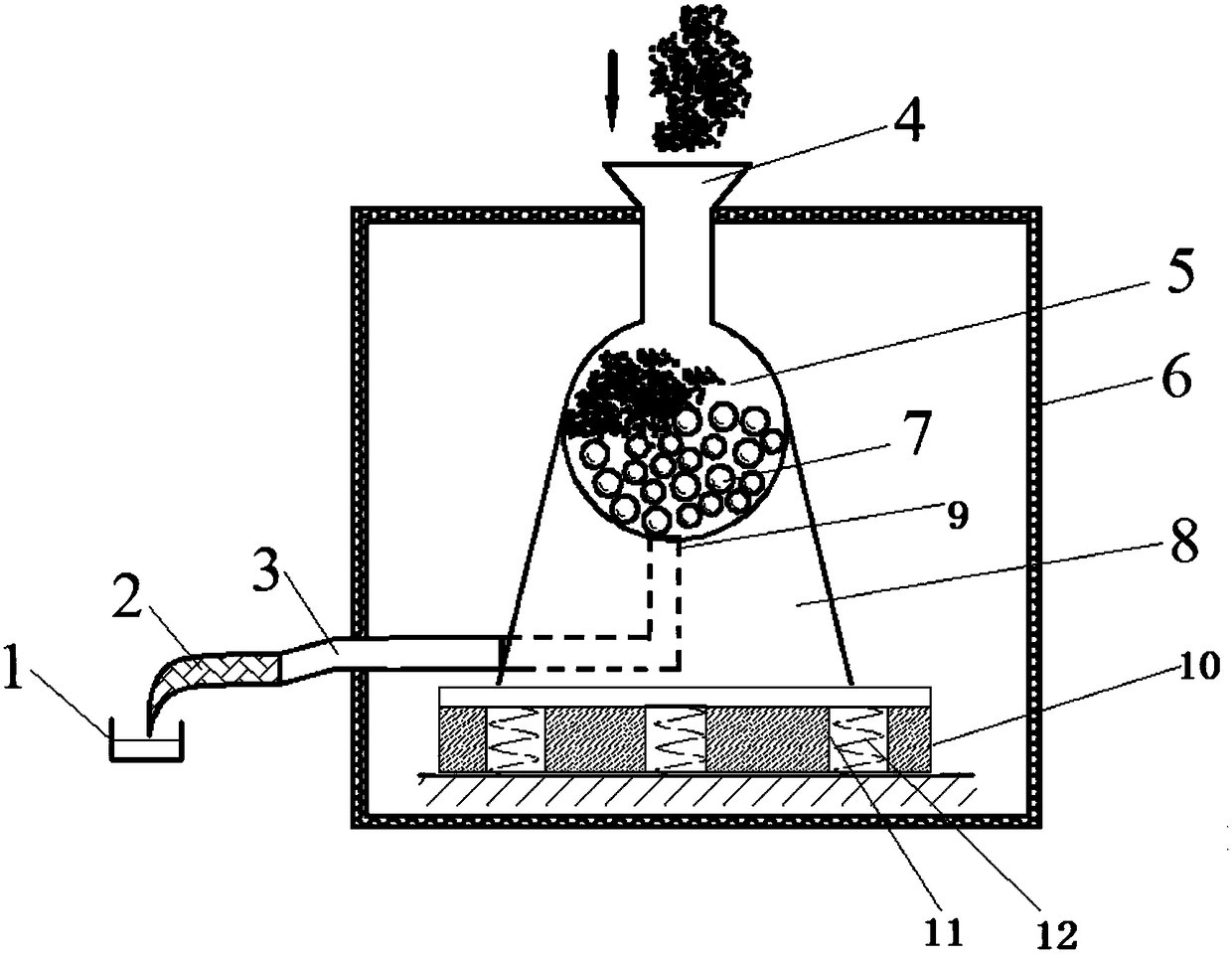

[0057] Such as figure 2 As shown, this embodiment is improved on the basis of Embodiment 1 or 2, and a shock absorption mechanism is provided between the vibrating mill mechanism 8 and the fixed surface.

[0058] As a preferred manner, the shock absorbing mechanism is a shock absorbing sand box, which includes a box body and sand contained in the box body. The sand can absorb mechanical shock and play a shock absorbing effect.

[0059] As a preferred manner, the shock-absorbing mechanism is a shock-absorbing pad 10.

[0060] As a preferred manner, the shock-absorbing pad 10 is provided with shock-absorbing cavities 11 arranged vertically in a matrix distribution, and shock-absorbing springs 12 arranged in the same direction are arranged in the shock-absorbing cavity 11.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com