Square automobile chassis component forming technology

A technology of automobile chassis and molding process, which is applied to vehicle parts, transportation and packaging, etc., and can solve problems such as difficult material removal, failure to form, and stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below by means of the accompanying drawings, but the present invention is not limited only to the following embodiments.

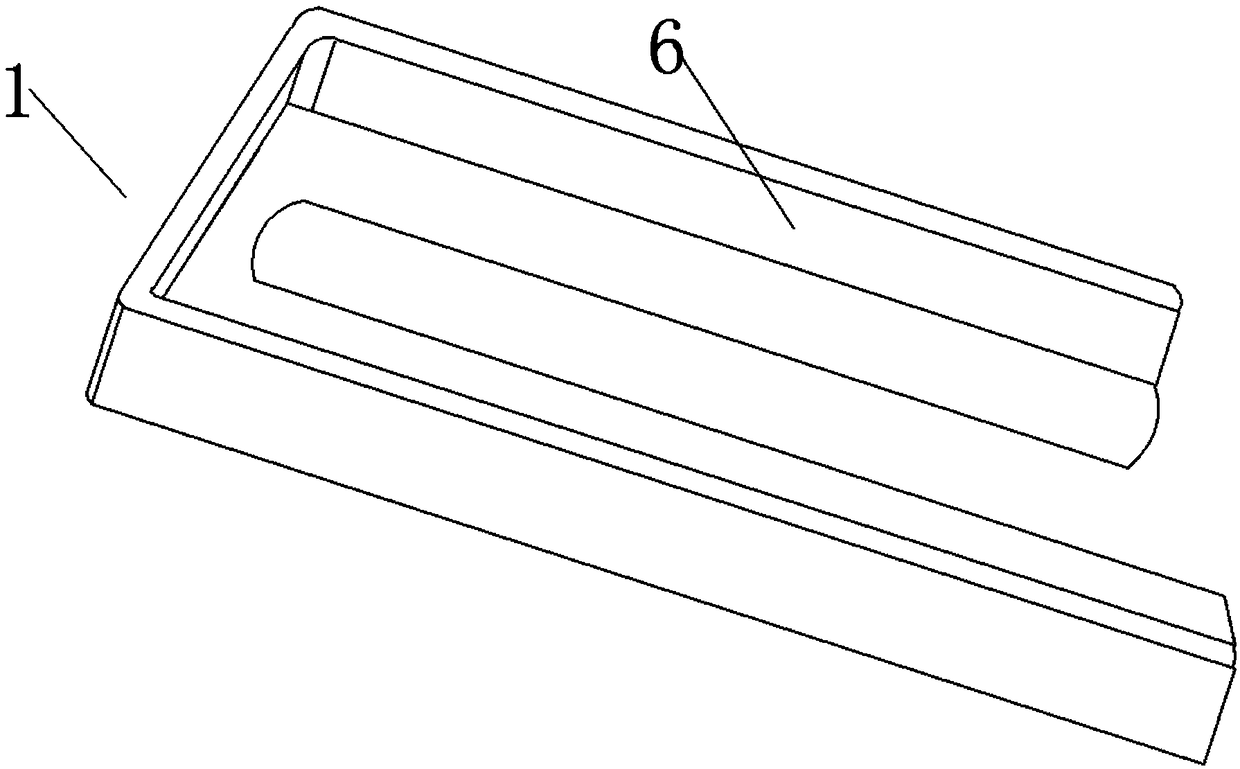

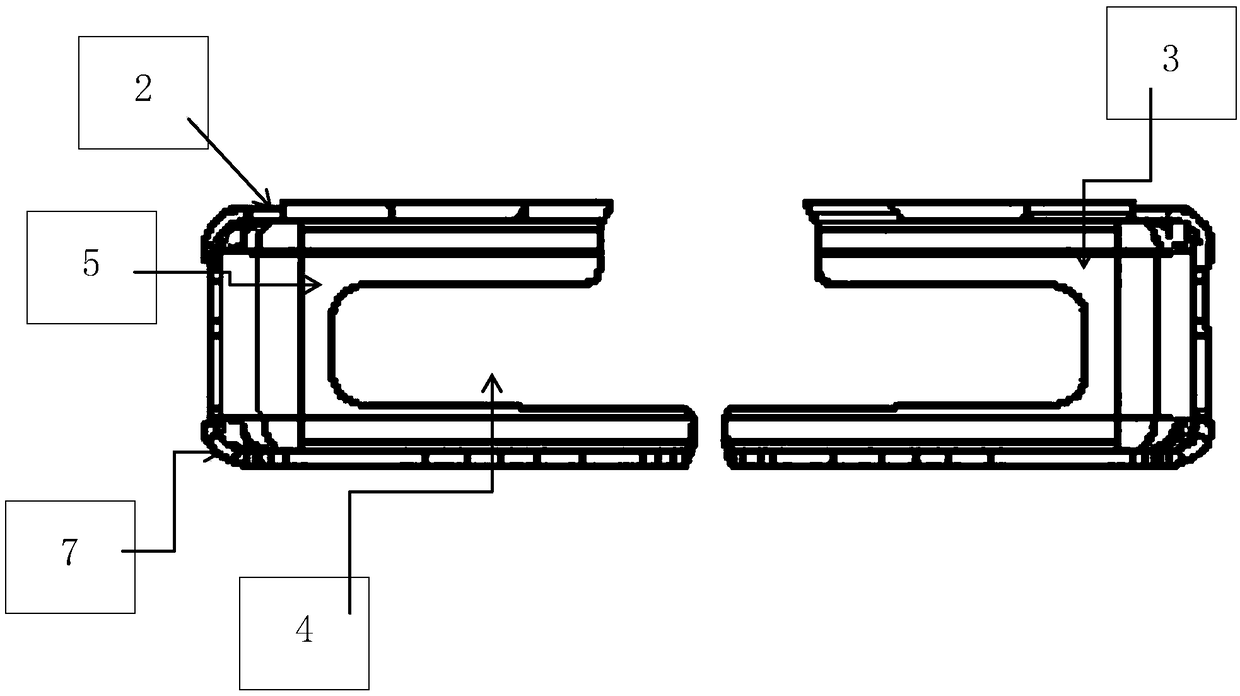

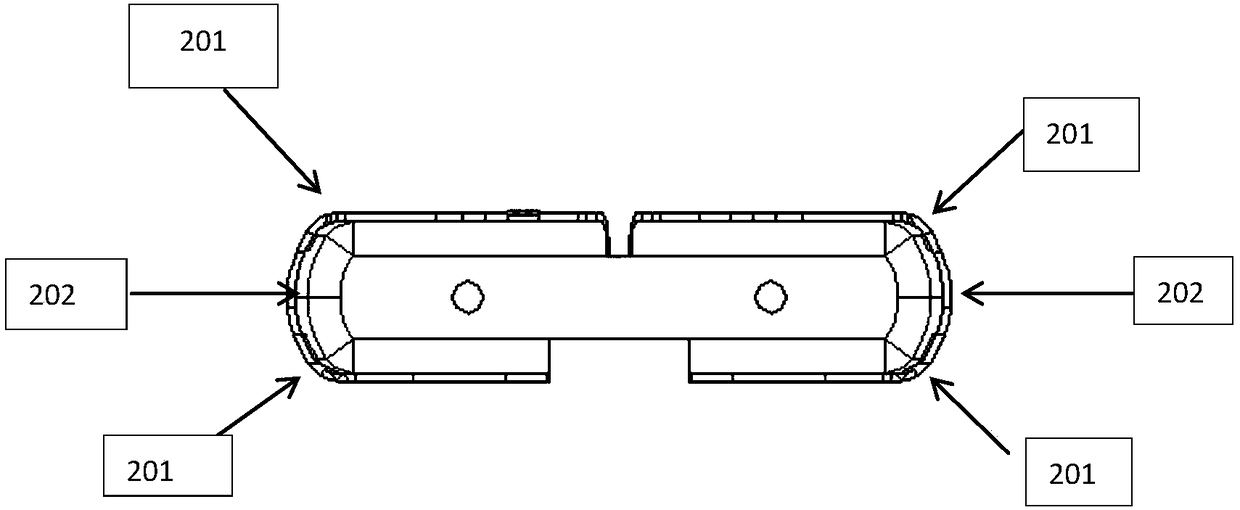

[0016] to attach Figure 1-2 Shown structure is based on processing, as can be seen from the accompanying drawings, the structure of the quadrangular automobile chassis part of the present invention is as follows: comprise the quadrangular automobile chassis part body 1, and the described quadrangular part body includes the left quadrangular zero Parts single piece 2 and right square parts single piece 3, and the left square parts single piece and the right square parts single piece are arranged symmetrically; the left square parts single piece or the right square parts single piece include The bottom 5 of the U-shaped notch 4, the periphery of the base plate is vertically extended with a side 6, and the R angle 7 formed by the side is close to a right angle; A single piece is a group of planar m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com