Auxiliary device used for removal of steering gear rotor of ship

A technology of auxiliary devices and steering gears, which is applied in hand-held tools and manufacturing tools, etc., can solve problems such as the difficulty of dismantling the rotors of ship steering gears, and achieve the effects of stable force direction, prevention of jamming, and strong mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

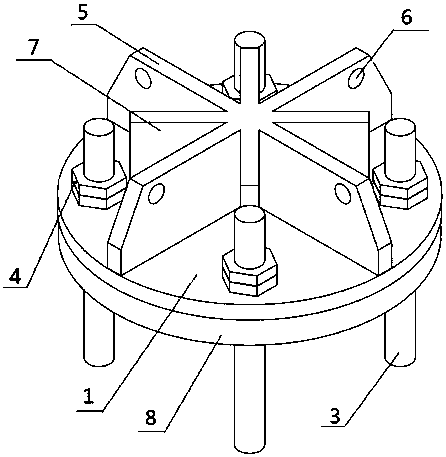

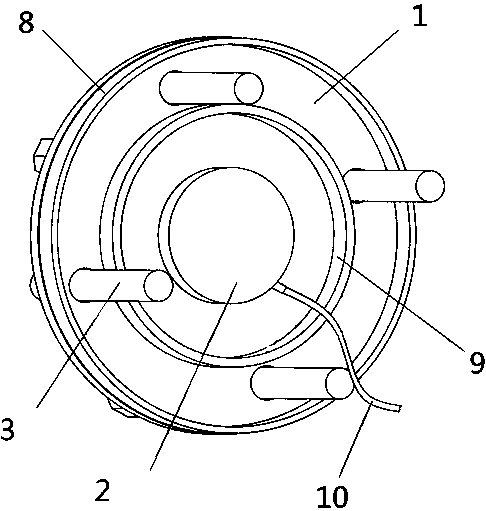

[0020] Example: such as figure 1 and figure 2 As shown, an auxiliary device for removing the rotor of a ship's steering gear includes a fixed plate 1 and a hydraulic cylinder 2. The fixed plate 1 is circular, and the fixed plate 1 is provided with four vertical through holes. The four vertical through holes are arranged symmetrically with the center of the fixed plate 1, and studs 3 are perforated in the four vertical through holes, and the upper ends of the studs 3 extend above the fixed plate 1, The upper ends of the studs 3 are fastened with positioning nuts 4, and the lower ends of the studs 3 extend below the fixing plate 1, and the upper surface of the fixing plate 1 is provided with four first rib plates 5 , the four first rib plates 5 are radially distributed on the upper surface of the fixed plate 1 with the center of the fixed plate 1 as the center, and the four first rib plates 5 are perpendicular to each other to form four right angles. The bisectors of the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com