Application method for treating gas in upper corner of coal mine based on water vapor vortex fluid

A vortex and gas technology, which is applied in the field of gas application methods in the upper corners of mines, can solve problems such as the inability to generate gas accumulation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

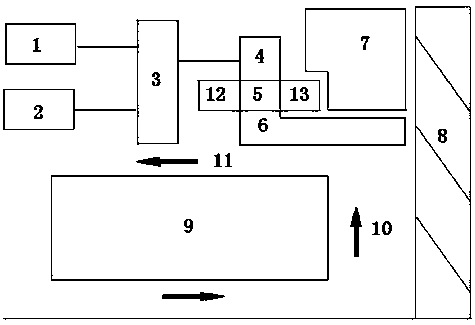

[0021] A device for controlling gas in upper corners of coal mines based on water-air vortex fluid, the device is composed of a pressure water circuit 1, a pressure gas circuit 2, an intelligent controller 3, a gas-water vortex generating device 4, a fixed pillar 5, and an air flow guide overflow fold Flow plate 6, upper corner 7, goaf 8, working face coal wall 9, coal mining face 10, main airflow 11, top plate 12 and bottom plate 13, pressure water channel 1 and pressure gas channel 2 are used for gas-water atomization The power source of the device, their working pressure range is 0.6Mpa, and the dosage volume ratio is 1:0.05. The air-water vortex generating device 4 is respectively connected to the pressure water circuit 1 and the pressure gas circuit 2 through the intelligent controller 3, and is supported by a fixed pillar 5 Between the top plate 12 and the bottom plate 13, the fixed pillar 5 is arranged separately, the fixed pillar 5 is arranged in the upper area of the...

Embodiment approach 2

[0030] The working pressure is 0.2Mpa, the dosage volume ratio is 1:0.001, the fixed pillar 5 is arranged separately, and the air-water vortex generating device 4 is fixed on the upper part of the fixed pillar 5 close to the upper corner 7, so that it is inclined upward at an angle of 30 degrees. The air-water atomized vortex fluid is sprayed toward the position of the top plate 12, and the fixed pillar 5 is arranged in the middle of the upper corner 7, and the others are the same as in the first embodiment.

Embodiment approach 3

[0032] The working pressure is 0.5Mpa, the dosage volume ratio is 1:0.03, the fixed pillar 5 is arranged separately, and the air-water vortex generator 4 is fixed on the upper part of the fixed pillar 5 close to the upper corner 7, so that it is inclined at an upward angle of 35 degrees. Direction sprays air-water atomized vortex fluid to the position of the top plate 12, the fixed pillar 5 is arranged at the lower part of the upper corner 7, and the others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com