Application method of dry-fog dust suppression nozzle anti-icing equipment

An anti-icing and nozzle technology, applied in the direction of separation methods, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of nozzle icing and non-icing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

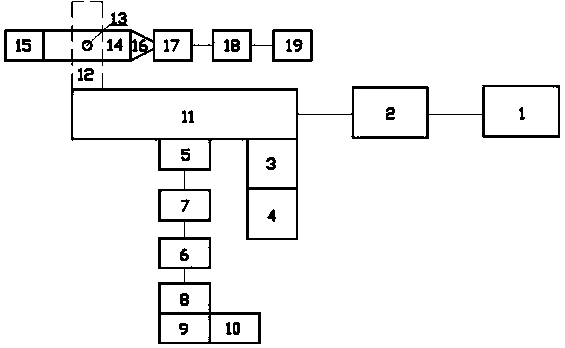

[0025] An anti-icing device for dry mist dust suppression nozzles, which is characterized in that an antifreeze cleaning liquid composed of silicone oil emulsified and water in proportion to each other is filled into the entire liquid system, and sprayed from the nozzle, free from the entire The water molecules and air in the liquid path system are discharged or merged into the antifreeze cleaning liquid. The entire liquid path system and the dry mist dust removal nozzle will not produce icing. The water hole is always kept unobstructed. The device passes on the liquid path. The additional dry mist dust suppression nozzle anti-icing device treats the outdoor fluid system, so that the outdoor fluid system, nozzles, and nozzle water holes have no possibility of icing in the cold season in the field, realizing the purpose of anti-icing of the dry mist dust suppression nozzle The device consists of a pressure water source 1, a pressure water source valve 2, a low-level discharge por...

Embodiment approach 2

[0034] The nozzle water inlet 13 has a diameter of 0.9 mm, and the nozzle water inlet 13 is symmetrically distributed into two; the others are the same as the first embodiment.

Embodiment approach 3

[0036] The nozzle inlet hole 13 has a diameter of 0.9 mm, and the nozzle inlet hole 13 is symmetrically distributed in four; the others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com