A Stamping Die That Can Improve Product Precision

A stamping die and precision technology, applied in the direction of forming tools, manufacturing tools, storage devices, etc., can solve the problems of poor positioning accuracy of positioning pins, product accuracy can not meet the requirements, etc., to improve product accuracy, reduce maintenance costs, improve durability Effect of Grindness and Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

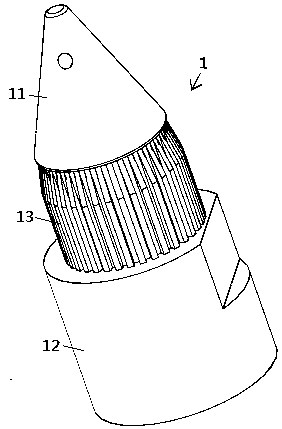

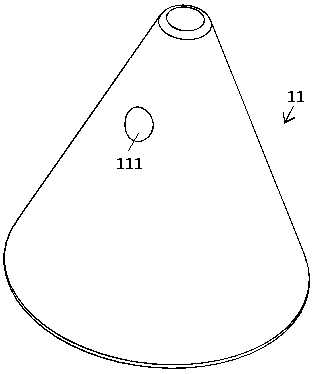

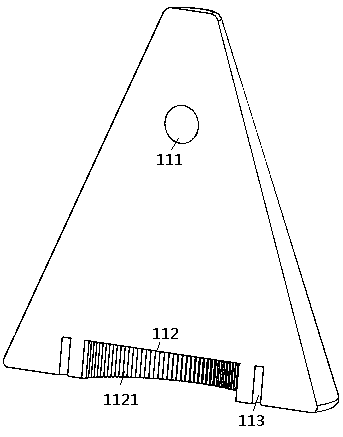

[0037] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a stamping die that can improve product precision in this embodiment includes an upper die and a lower die that cooperates with the upper die, and a positioning pin 1 with adjustable diameter is arranged on the lower die, such as figure 1As shown, the positioning pin 1 includes a guide section 11, a positioning section 13 and a fixing section 12 arranged in sequence from top to bottom, and the central axes of the guiding section 11, the positioning section 13 and the fixing section 12 are all coincident, wherein the fixing The segment 12 is fixedly connected to the lower die, the guide segment 11 and the fixed segment 12 are single-sidedly engaged to lock the guide segment 11, and the positioning segment 13 and the guide segment 11 are engaged by teeth to be double-sided. To adjust the diameter of the positioning section 13. That is, the gear mesh transmission between the guide section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com