Support method for normally installed hatch coaming of ultra-large container ship

A container ship and support method technology, applied in the direction of hull, hull deck, ship parts, etc., can solve problems such as heavy workload and damage to hatch coaming structure, and achieve the effect of controlling welding deformation, reducing the number of rollovers, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

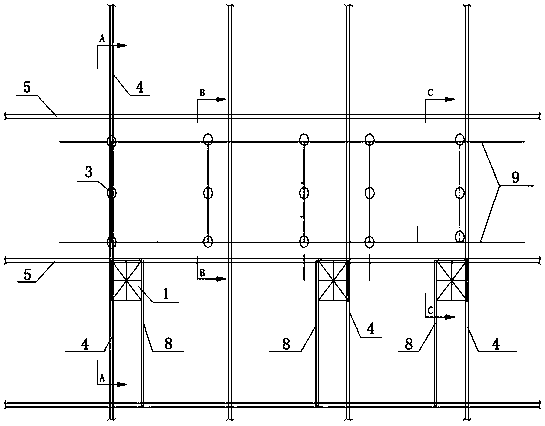

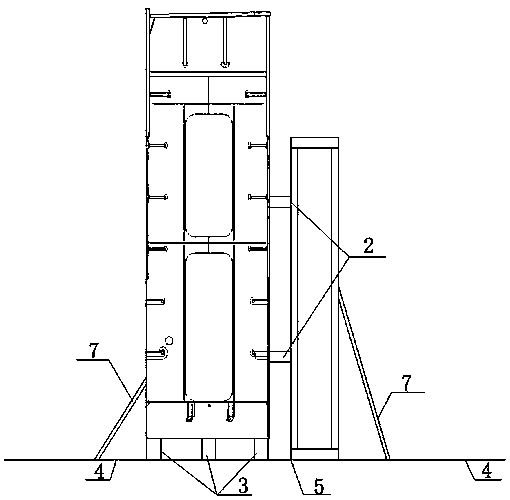

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

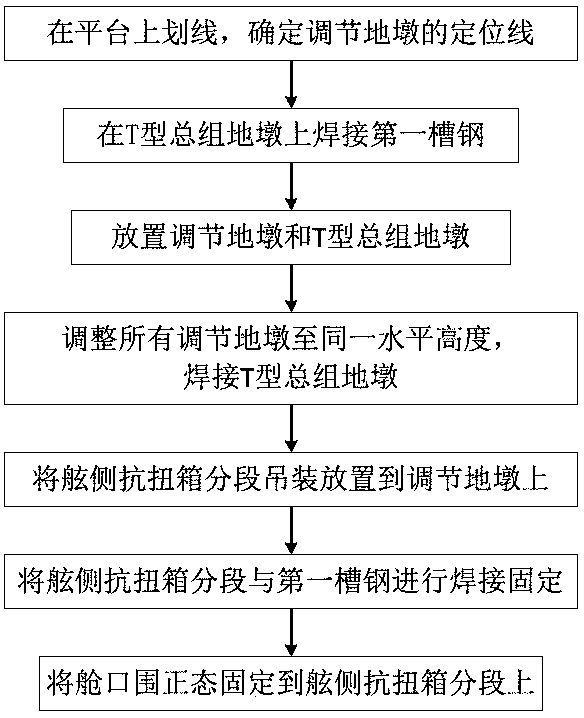

[0038] combine Figure 1-Figure 6 Describe this embodiment mode, the support method for the normal installation hatch coaming of ultra-large container ship of the present invention, overcome the too much channel steel installed in the existing installation method, the grinding workload is heavy when removing channel steel, the hatch coaming welding Destroy the deck paint, increase the workload of scaffolding during welding, and affect the construction period ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com