Rising and falling device for die-casting fitting

A technology for lifting devices and die-casting parts, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc. It can solve problems such as inaccurate loading of robots, unstable workpiece conveying positions, and many burrs in die-casting parts, etc., to achieve automation High degree, improve production efficiency, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples, but the examples are only exemplary and do not constitute any limitation to the scope of the present invention. Those skilled in the art should understand that the details and forms of the technical solutions of the present invention can be modified or replaced without departing from the spirit and scope of the present invention, but these modifications and replacements all fall within the protection scope of the present invention.

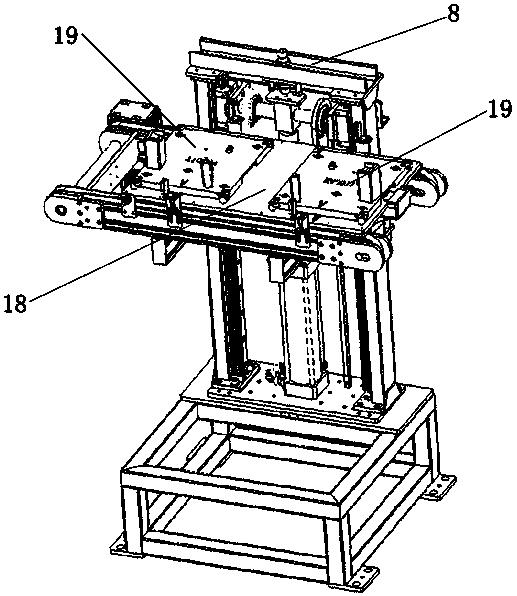

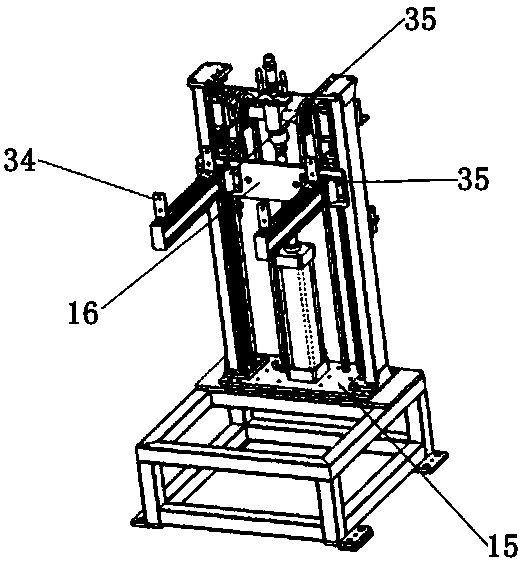

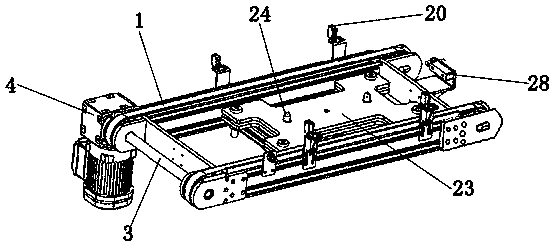

[0028] A lifting device for die castings, such as Figure 1-7 As shown, the lifting device includes a lifting device, a transmission device and a positioning device; the lifting device includes a lifting base 6, a column 7, a beam 8 and a lifting cylinder 9, and the transmission device includes a drive motor 4, a drive shaft 3 and a synchronous With 1, the positioning device includes a tooling tray 18, a positioning fixture 19, an upper top plate 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com