Ultra-thin ditch-making device filled with copper-free mesh for ditch pipe

An ultra-thin, ditch technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of reducing the efficiency of ditch control ditch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

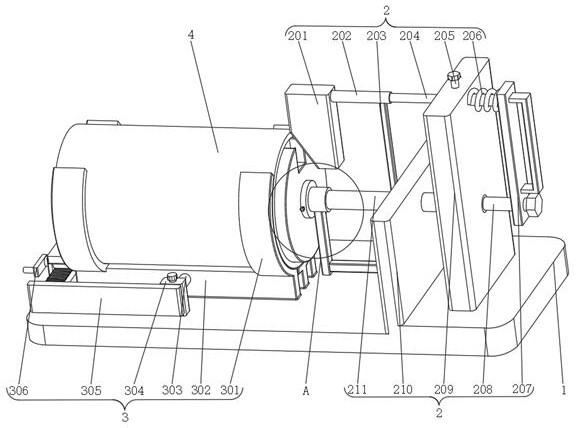

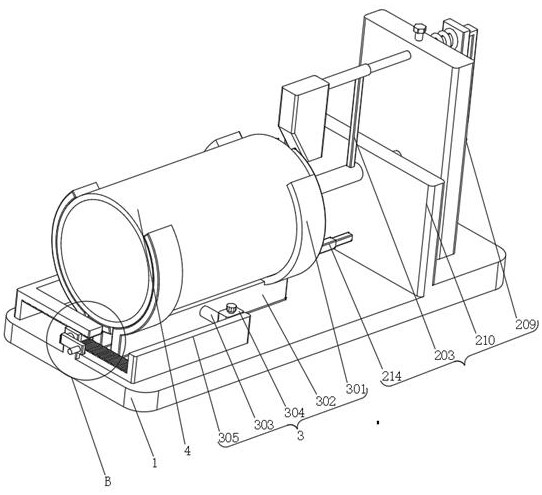

[0023] Example 1, such as Figure 1-5 As shown, the present invention provides an ultra-thin ditch control device without copper mesh filling, including a base 1 and an auxiliary device 2, the surface of the base 1 is provided with the auxiliary device 2, and the surface of the base 1 is provided with an adjustment device 3.

[0024] Let's talk about the specific setting and effect of its auxiliary device 2 and regulating device 3 in detail.

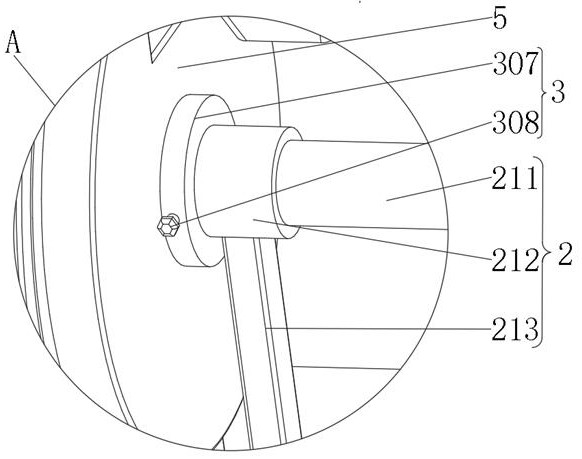

[0025] Such as figure 1 with figure 2 As shown, the auxiliary device 2 includes a fixed block 209, the surface of the fixed block 209 is fixedly connected with the base 1, the surface of the fixed block 209 is provided with a circular groove, and the inner wall of the circular groove is rotatably connected with a rotating cylinder, and the surface of the rotating cylinder is screwed. There is a threaded rod 208, the surface of the threaded rod 208 is threadedly connected with a threaded cylinder 211, the surface of the threaded cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com