A Control Method for Narrow Hardenability Bandwidth of Gear Steel

A control method, a technology of hardenability, applied in the field of gear steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

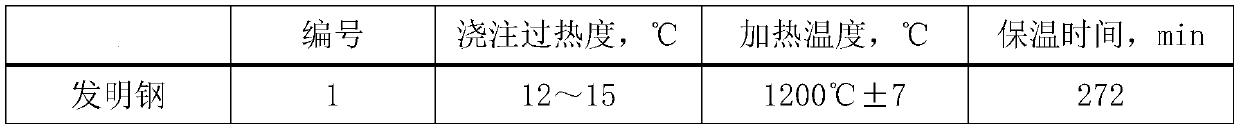

[0020] Below through embodiment, the specific implementation method of the present invention is further described.

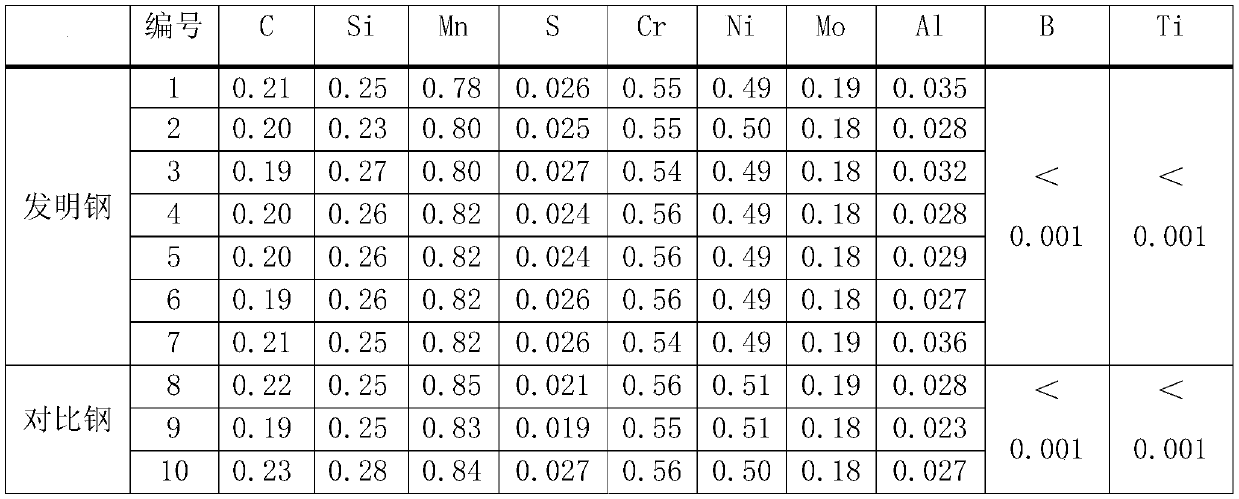

[0021] Taking Cr-Ni-Mo series gear steel as an example, its target composition is controlled as follows:

[0022] C: 0.20%, Si: 0.25%, Mn: 0.80%, Cr: 0.55%, Ni: 0.50%, Mo: 0.18%, Ti: <0.001%, Al: 0.03%, B: <0.001%, S: 0.025 %.

[0023] According to the target composition control of the steel grade, select the data of 10 furnaces in which C is controlled within the range of 0.19% to 0.21% in the production of the steel grade, and the C content is respectively: 0.191%, 0.192%, 0.195%, 0.197%, 0.199%, 0.199%, 0.203%, 0.205%, 0.207%, 0.210%.

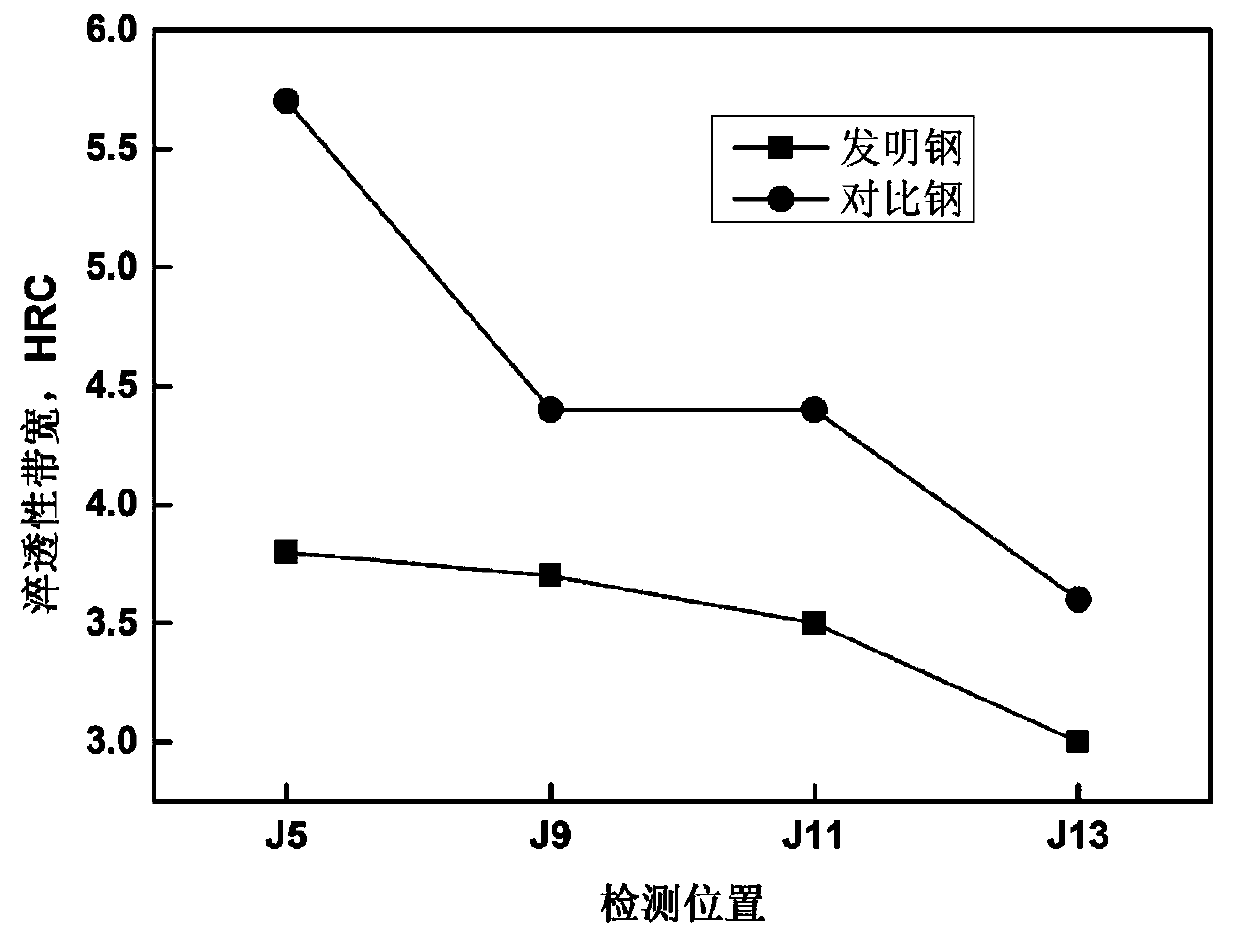

[0024] According to the composition data of 10 heats of steel and the actual test results of hardenability, the calculation formula of hardenability was optimized, and the optimized calculation formula was obtained. On the basis of the optimized formula, calculate the upper and lower line components of C, Si, Mn, Cr, Ni, Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com