DQ-Q&T method for 1000MPa grade steel plate with thickness less than 80mm

A technology of DQ-Q&T and steel plates for hydropower, which is applied in the field of DQ-Q&T, can solve the problems that the steel plates for hydropower cannot reach the tensile strength, and achieve the effect of excellent plasticity and low-temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

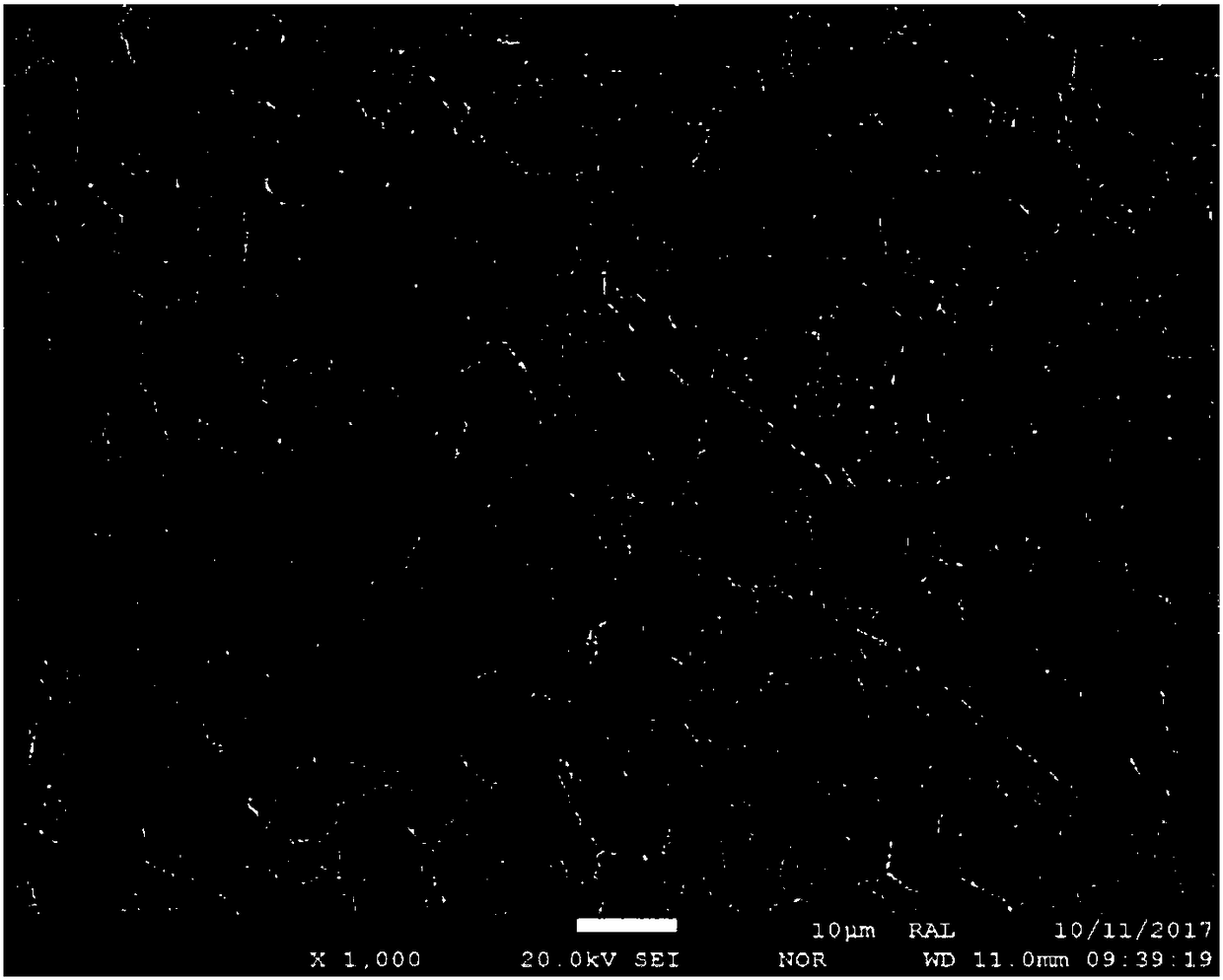

Embodiment 1

[0029] Smelt molten steel according to the set composition and continuously cast it into slab, its composition by weight percentage is C 0.13%, Mn 1.2%, P 0.008%, S 0.001%, Si 0.3%, Ni 1.4%, Cr 0.35%, Alt 0.04% , Nb 0.015%, Mo0.4%, V 0.035%, Ti 0.016%, B 0.0015%, and the balance is Fe. Casting into a continuous casting slab with a thickness of 320mm, the slab has been inspected, stacked for 48 hours, and the surface of the slab has been inspected. The surface quality of the slab is good, and there is no need to grind the slab.

[0030] The slab is heated by a walking heating furnace, the first stage is heated to 700°C, the second stage is heated to 1110°C, the third stage is heated to 1200°C, the soaking time of the third heating stage is 70min, and the total heating time is 330min. Before the slab is hot-rolled, it is dephosphorized by high-pressure water to remove the iron oxide scale on the surface of the slab. The slab is rolled in two stages by using a 4700mm four-roll m...

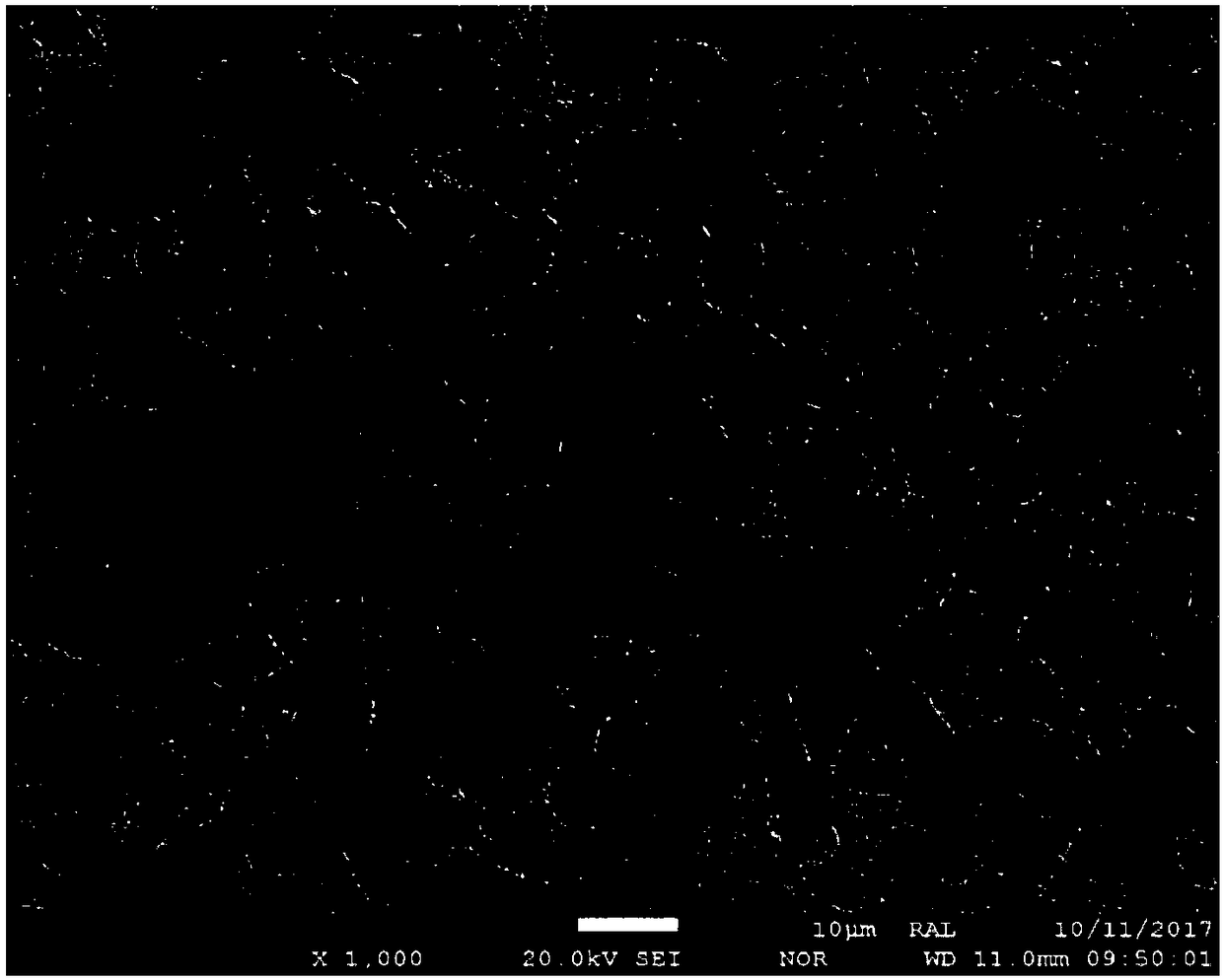

Embodiment 2

[0035] Smelt molten steel according to the set composition and continuously cast it into slab, its composition by weight percentage is C 0.13%, Mn 1.2%, P 0.008%, S 0.001%, Si 0.3%, Ni 1.4%, Cr 0.35%, Alt 0.04% , Nb 0.015%, Mo0.4%, V 0.035%, Ti 0.016%, B 0.0015%, and the balance is Fe. Casting into a continuous casting slab with a thickness of 320mm, the slab has been inspected, stacked for 48 hours, and the surface of the slab has been inspected. The surface quality of the slab is good, and there is no need to grind the slab.

[0036] The slab is heated by a walking heating furnace, the first stage is heated to 710°C, the second stage is heated to 1100°C, the third stage is heated to 1200°C, the soaking time of the third heating stage is 60min, and the total heating time is 330min. The slab is rolled in two stages by using a 4700mm four-roll mill. The rough rolling pass is 5 passes, the starting rolling temperature is 1150°C, the final rolling temperature is 1055°C, the total...

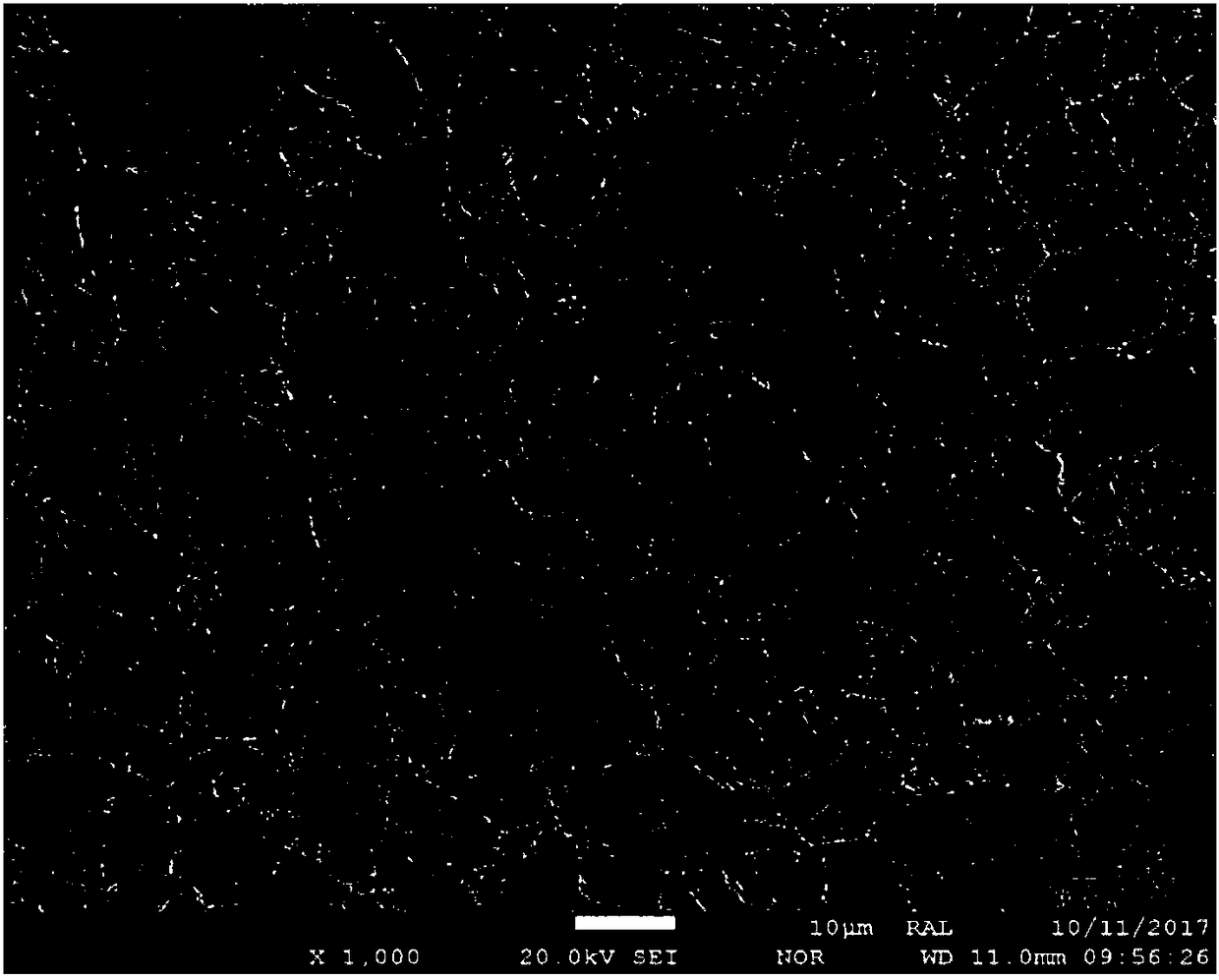

Embodiment 3

[0041] Smelt molten steel according to the set composition and continuously cast it into slab, its composition by weight percentage is C 0.13%, Mn 1.2%, P 0.008%, S 0.001%, Si 0.3%, Ni 1.4%, Cr 0.35%, Alt 0.04% , Nb 0.015%, Mo0.4%, V 0.035%, Ti 0.016%, B 0.0015%, and the balance is Fe. Casting into a continuous casting slab with a thickness of 320mm, the slab has been inspected, stacked for 48 hours, and the surface of the slab has been inspected. The surface quality of the slab is good, and there is no need to grind the slab.

[0042] The slab is heated by a walking heating furnace, the first stage is heated to 710°C, the second stage is heated to 1110°C, the third stage is heated to 1220°C, the soaking time of the third heating stage is 70min, and the total heating time is 340min. The slab is rolled in two stages by using a 4700mm four-roll mill. The rough rolling pass is 5 passes, the starting rolling temperature is 1150°C, the final rolling temperature is 1055°C, the total...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com