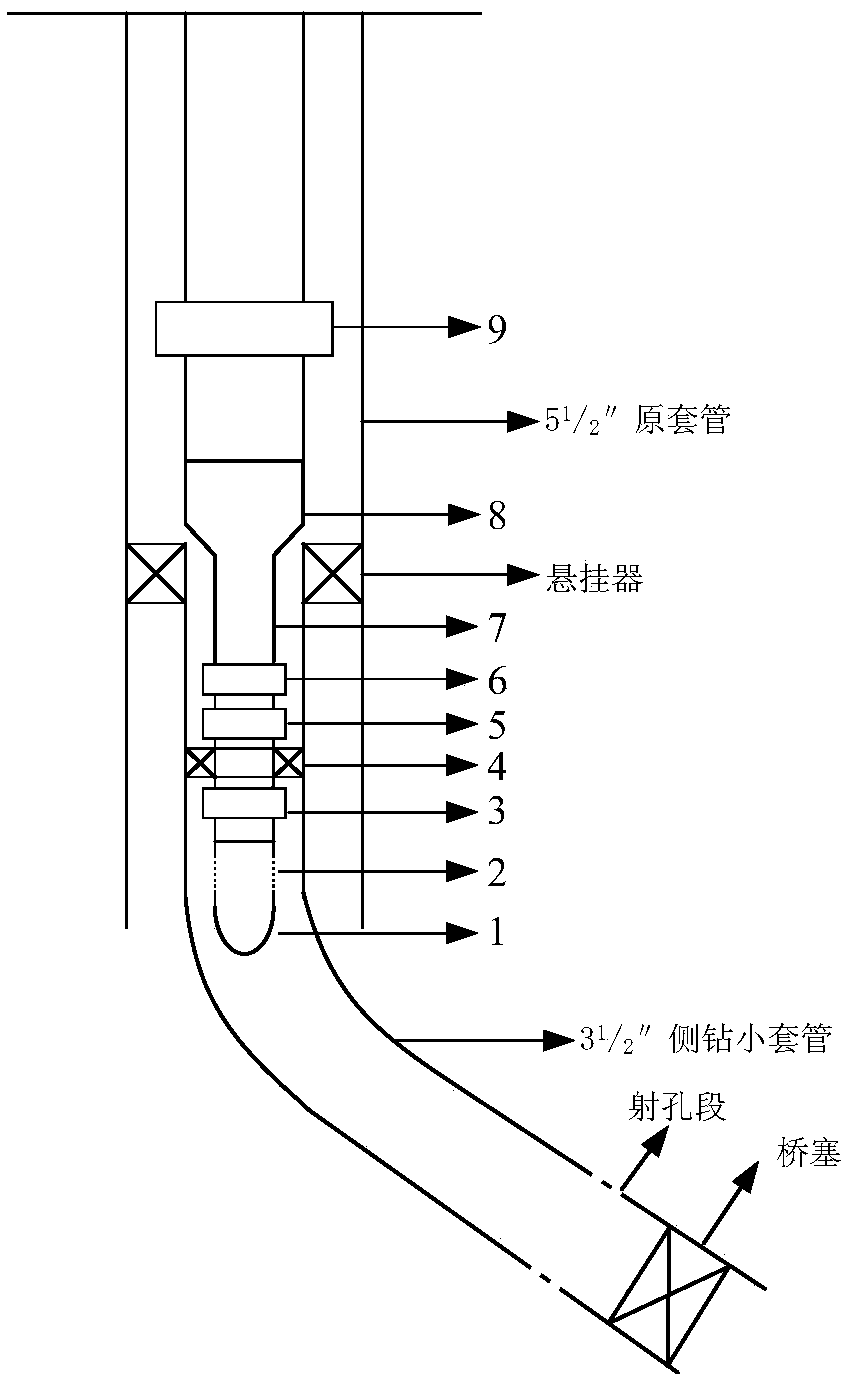

3.5-inch sidetracked slim hole sectioned fracturing pipe column

A staged fracturing and sidetracking technology, which is applied in the direction of wellbore/well components, earthwork drilling, production fluid, etc., can solve problems such as difficult handling, high risk of pipe sticking, and inability to realize staged fracturing, achieving Good segmentation effect and low risk of stuck pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

[0018] refer to figure 1 , the 3.5-inch sidetracking slimhole staged fracturing string of the present invention includes tubing, reinforcing pup joint 7, hydraulic anchor 6, backwash valve 5, packer 4, setting ball seat 3, sand blaster 2. Basket 1, 3.5-inch sidetracking small casing and the original casing; use a special tool to open a window somewhere in the original casing to drill a slim hole, and then use a 3.5-inch sidetracking small casing to cement and complete the well. Reinforcing nipple 7, hydraulic anchor 6, backwash valve 5, packer 4, setting ball seat 3, sand blaster 2 and catch basket 1 are all located in the small 3.5-inch sidetracking casing. Section 8 and safety drop 9 are all located in the original casing, tubing, safety drop 9, variable buckle nipple 8, reinforcement nipple 7, hydraulic anchor 6, backwash valve 5, packer 4, setting ball seat 3 , s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com