Optical fiber connector and method for assembling same

A technology of an optical fiber connector and an assembling method, which is applied in the field of communication, can solve the problems such as the inability to realize optical fiber docking, and achieve the effects of simple structure, convenient installation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] What the present invention proposes is a design idea of a connector, which can be applied to various types of connectors that are common at present, such as SC type, LC type, ST type, etc. Take the structure as an example, and further illustrate how the present invention is realized in conjunction with the accompanying drawings.

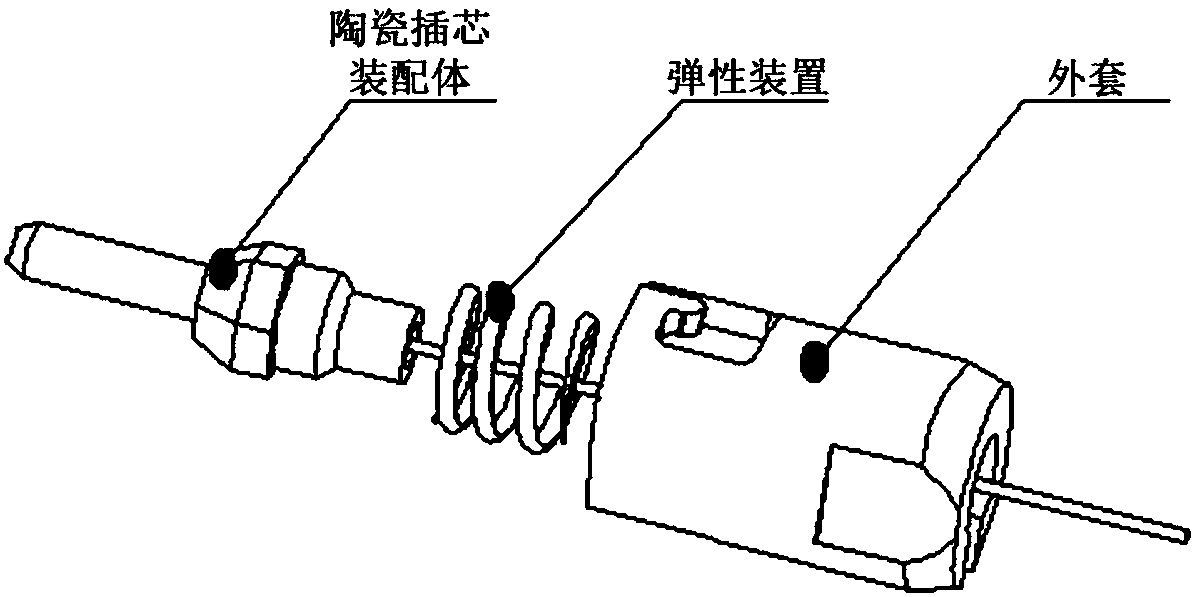

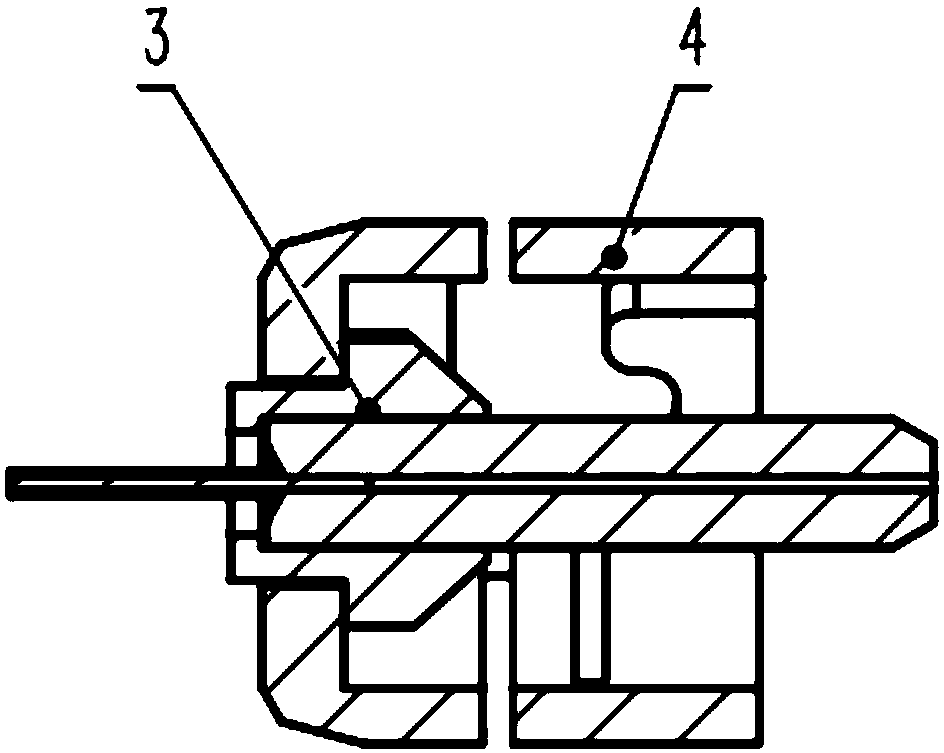

[0043] Such as figure 2 As shown, an optical fiber connector provided by Embodiment 1 of the present invention includes a jacket 4 and a ferrule assembly 3, the jacket 4 is a hollow structure, and the ferrule assembly 3 is arranged in the hollow structure of the jacket 4;

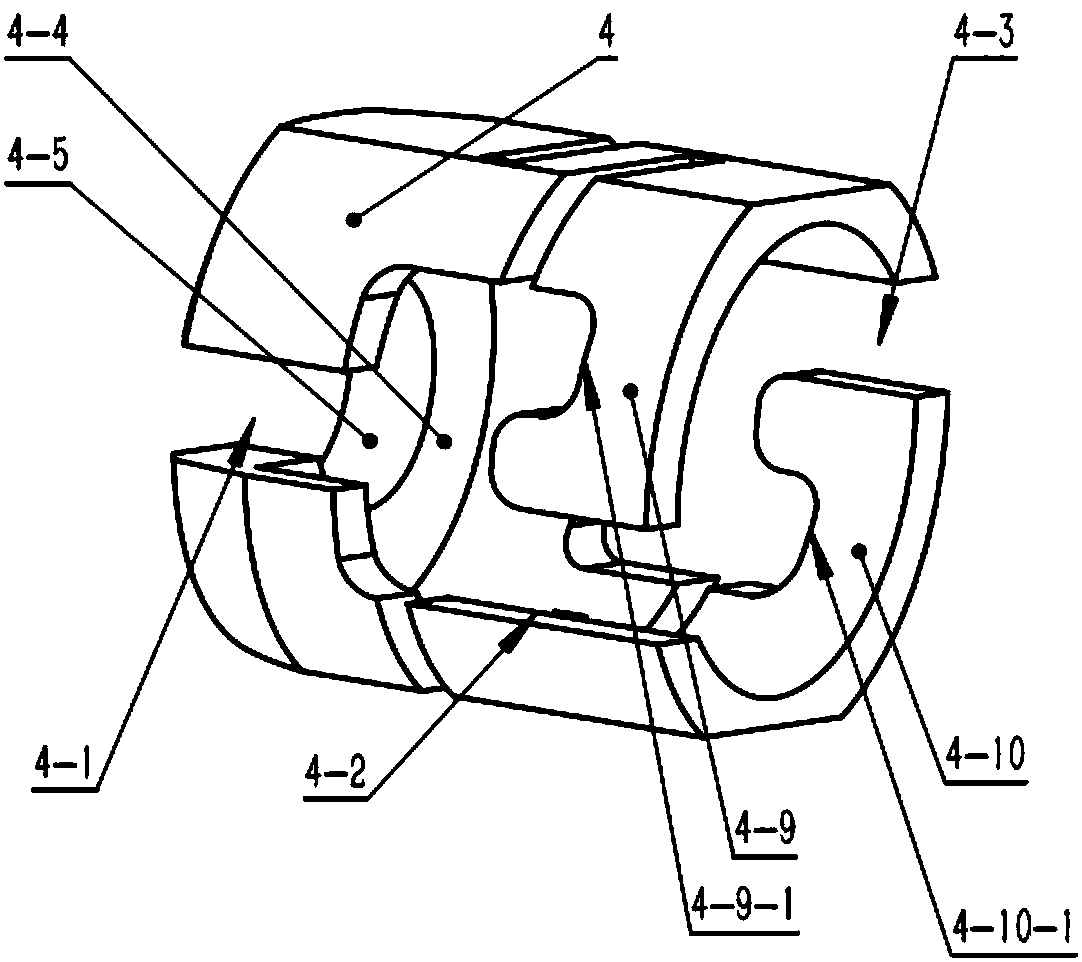

[0044] The outer wall of the jacket 4 is provided with a left open groove 4-2 and a right open groove 4-3, and the left open groove 4-2 and the right open groove 4-3 are circumferentially symmetrical with respect to the central axis of the jacket 4;

[0045] Described overcoat 4 also comprises upper deformation groove 4-7, lower deformation groove 4-6, deformation bridge ...

Embodiment 2

[0057] This embodiment 2 is based on the embodiment 1, uses the above-mentioned optical fiber connector and its adapter, and uses the example of the butt coupling of the two to describe the assembly method of the connector of the present invention in detail, including: the ferrule assembly 3 first and the corresponding The adapter is pre-assembled, and the jacket 4 is then assembled with the corresponding adapter; during the assembly process of the jacket 4 and the corresponding adapter, the jacket 4 assembles the ferrule through the through channel of its pigtail groove 4-1 and the left open groove 4-2 The body 3 enters the inner cavity of the jacket 4, and then completes the assembly with the ferrule assembly 3.

[0058] Compared with the traditional assembly method, the assembly method of the optical fiber connector provided by the present invention can realize reverse assembly, allowing the parts that make up the connector to be placed in a small space in batches, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com