Electronics Manufacturing Process

A manufacturing process and technology for electronic products, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as inability to accurately absorb chips, uneven force on chips, and lower production efficiency, so as to reduce product defect rate, The effect of improving production efficiency and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

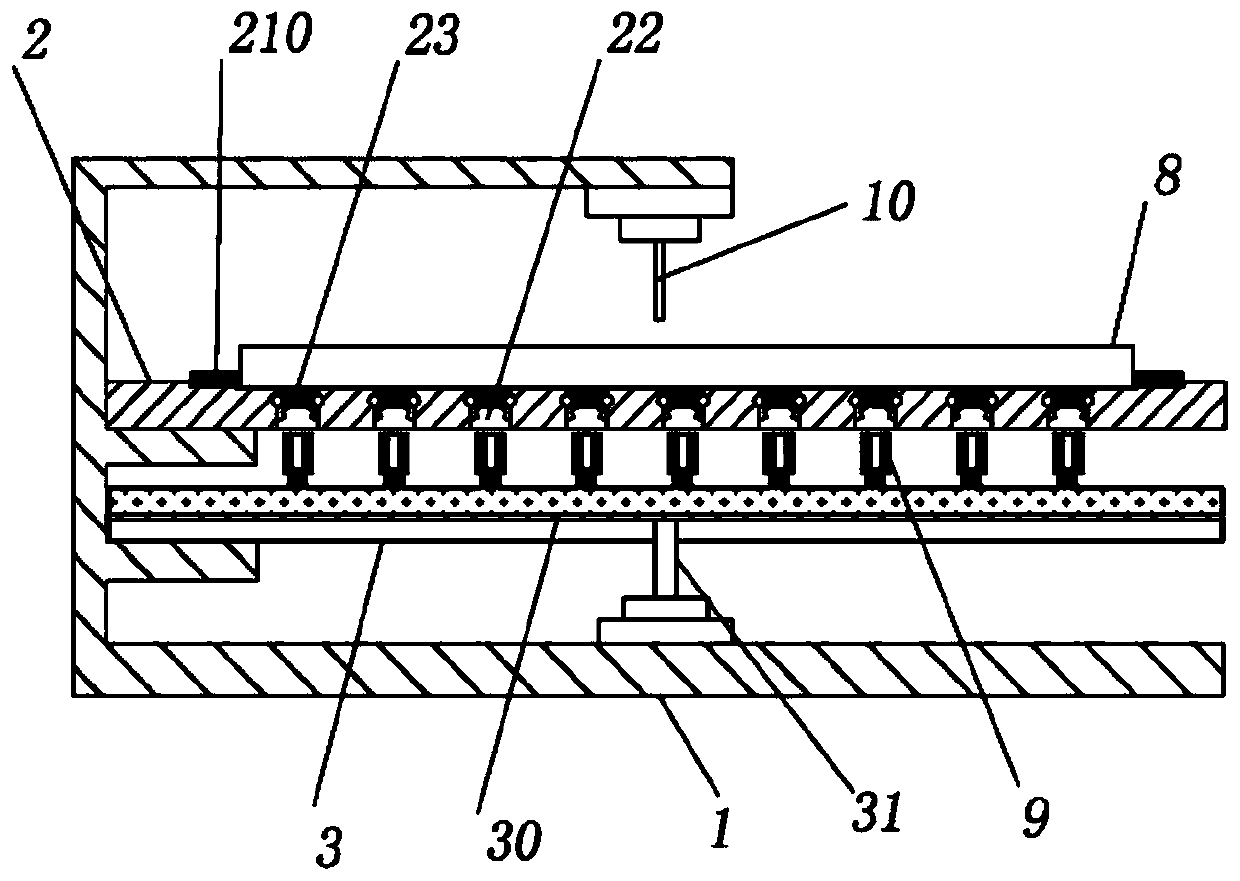

[0027] Basic as attached figure 1 Shown:

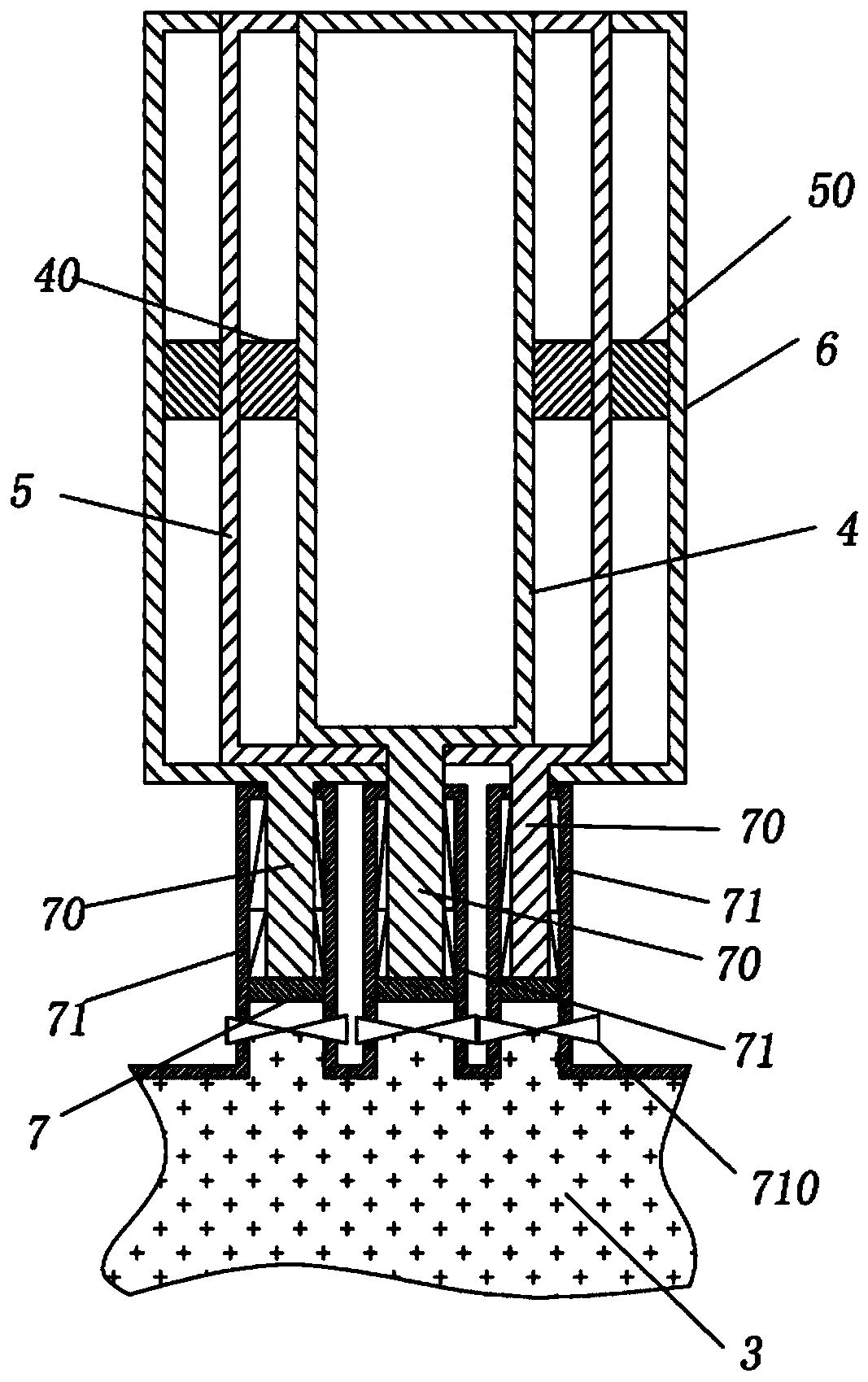

[0028] The electronic product manufacturing process adopts an ejector to eject chips, and the ejector includes a frame 1, a support table 2, an ejector mechanism 9, a hydraulic cylinder 3 and a push-pull part.

[0029] A dicing knife 10 for dicing the wafer 8 is telescopically connected above the frame 1 .

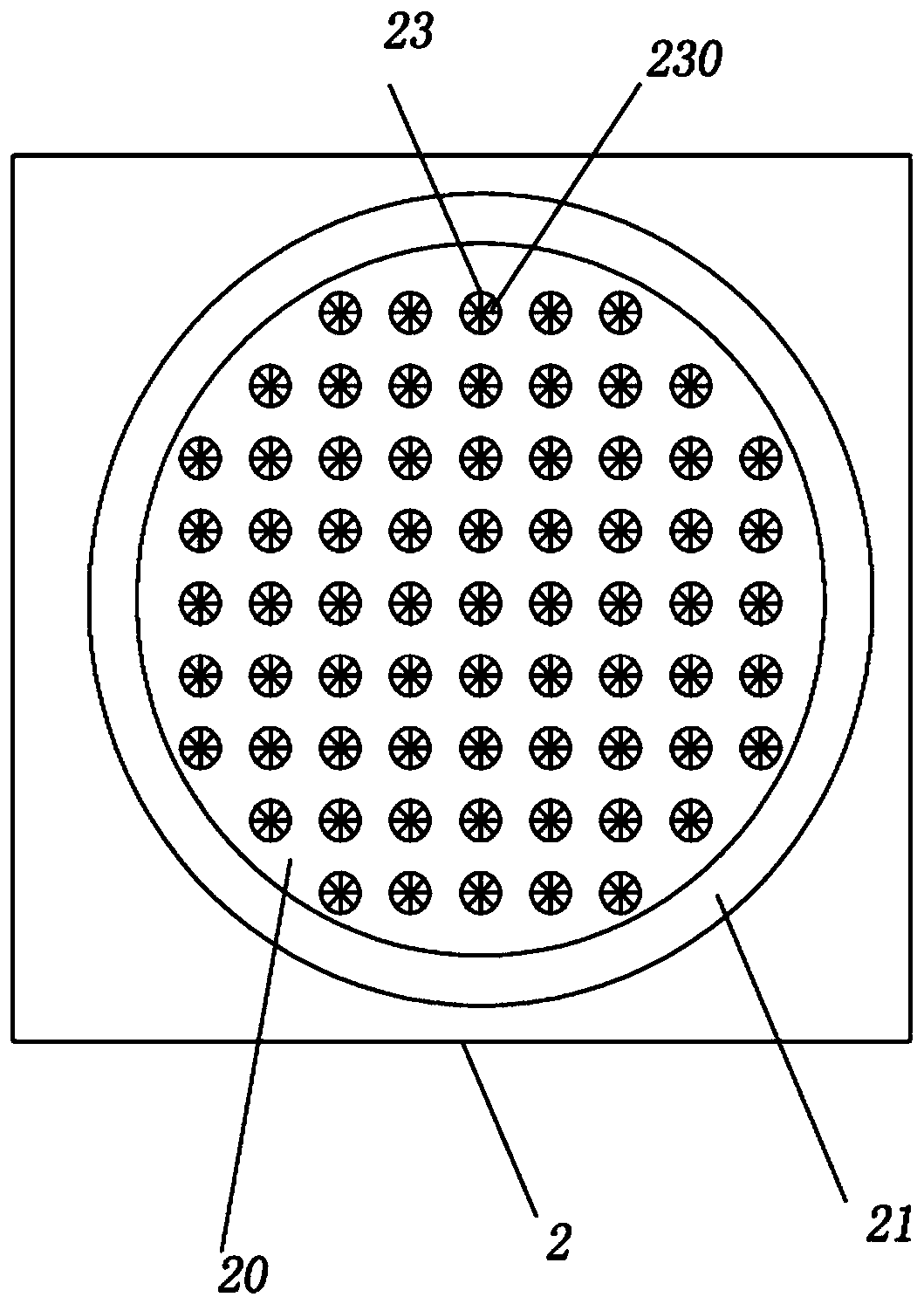

[0030] The support table 2 is used to support the wafer 8, such as figure 2 As shown, the shape of the support table 2 is a cube, and a circular groove 20 is provided in the center of the support table 2. The inner diameter of the groove 20 is consistent with the outer diameter of the wafer 8, so that after the wafer 8 is placed, Fixed wafer 8 effect. The circumferential direction of the groove 20 can also offer an iron ring placement groove 21, and the depth of the iron ring placement groove 21 is shallower than the depth of the groove 20, so that after putting the wafer 8 into the groove 20, the iron ring can also be placed ...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 lies in that: the extrusion pressure of the hydraulic oil in step B is 15MPa; the suction pressure of the vacuum suction head in step C is 2KPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com