Novel gas-liquid dual-purpose high-frequency rotary valve

A gas-liquid, dual-purpose technology, applied in the field of mechanical parts, can solve problems such as valve sleeve jamming and breaking, heating and deformation, increasing manufacturing difficulty and interchange cost, so as to reduce processing requirements, reduce friction, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings of the description.

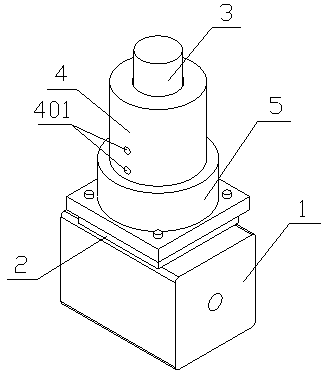

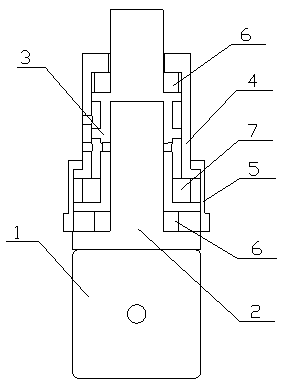

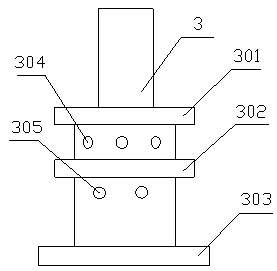

[0023] Such as Figure 1-5 As shown, the new air-liquid dual-purpose high-frequency rotary valve includes a base 1, a high-pressure chamber 101, a low-pressure chamber 102, a first high-pressure gas-liquid channel 103, a first low-pressure gas-liquid channel 104, a valve core 2, and a second high-pressure gas-liquid channel. Liquid channel 201, second low-pressure gas-liquid channel 202, high-pressure spool outlet 203, low-pressure spool circuit 204, first cut surface 205, second cut surface 206, transition core 3 first step 301, second step 302, second step Three steps 303 , first through hole 304 , second through hole 305 , valve sleeve 4 , oil inlet and outlet 401 , pressure sleeve 5 , thrust ball bearing 6 and sealing ring 7 . The valve core 2 is fixedly arranged on the base 1, the valve sleeve 4 is co-located on the valve core 2, the valve slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com