Air-actuated jacquard device

A cylinder and air source technology, applied in jacquard machines, textiles, textiles and papermaking, etc., can solve problems such as poor flexibility, and achieve the effects of improving stress conditions, facilitating installation, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

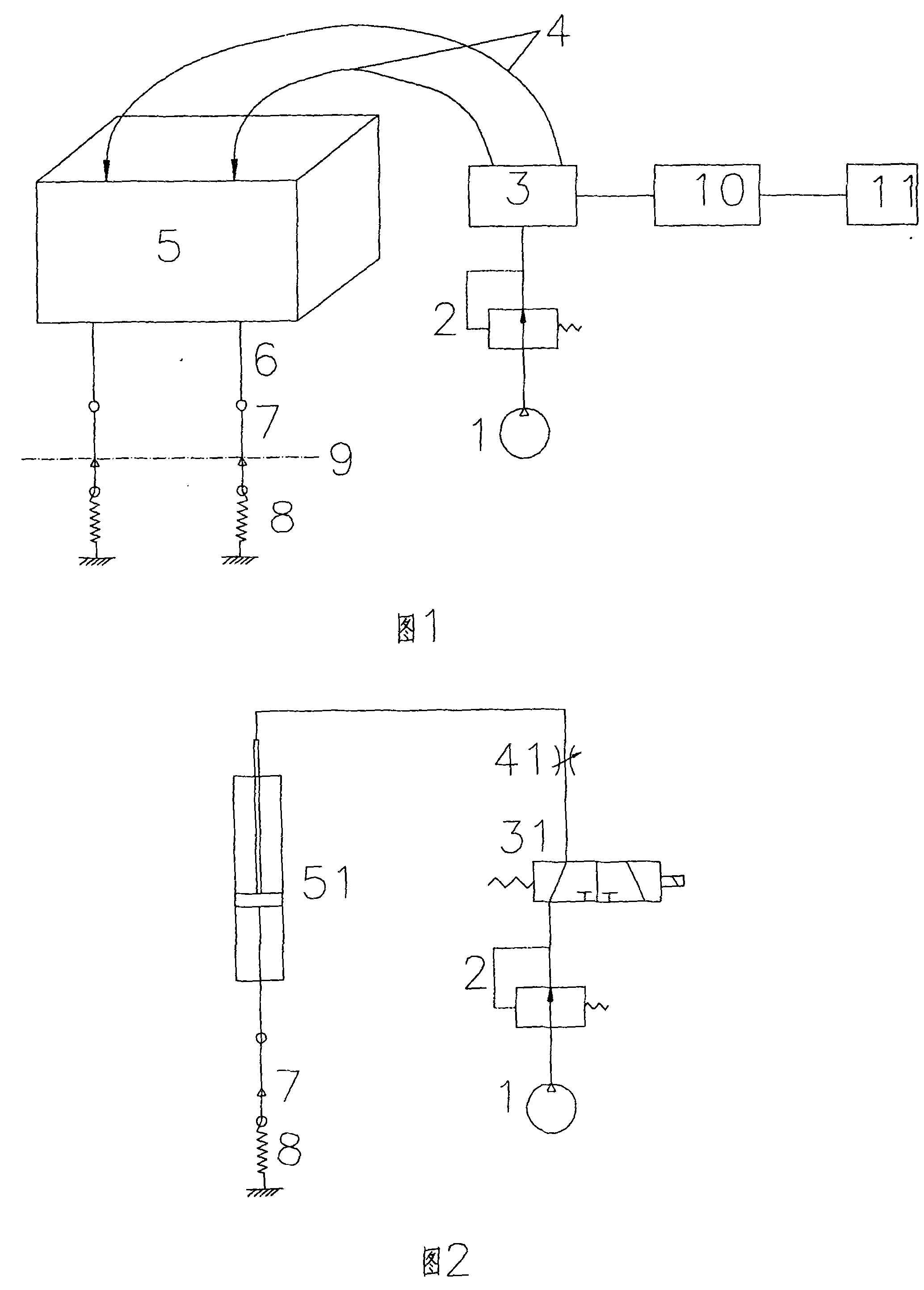

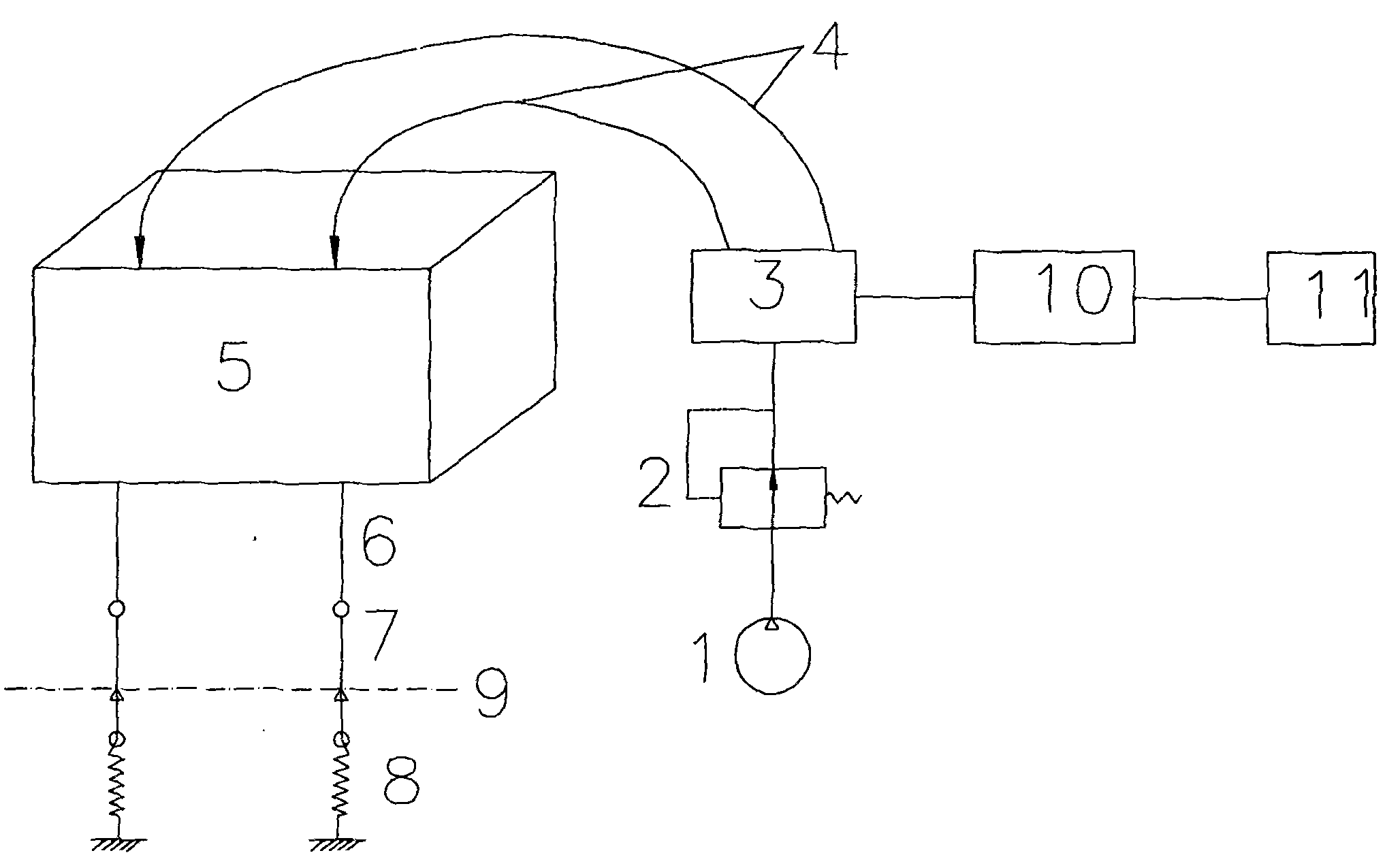

[0020] like figure 1 , shown in Fig. 2, a kind of pneumatic jacquard device described in the present embodiment, it comprises heddle 7, return heald spring 8 and the lifting unit that drives the heddle 7 that warp yarn 9 promotes, and described lifting unit is made of cylinder 51 and A pneumatic unit composed of an air source 1 , the heald 7 is connected to the pneumatic piston rod 6 in the cylinder 51 , and the cylinder 51 is pneumatically connected to the air source 1 through the air circuit 4 . Healds 7 at different positions for lifting warp yarns 9 at different positions are respectively pneumatically connected to cylinders 51 at different positions, and the cylinders 51 at different positions form an integrated cylinder group module 5 . An electromagnetic reversing valve 31 and a pressure regulating valve 2 that control the execution of the cylinder 51 are provided on the connecting air path 4 between the cylinder 51 and the air source 1. The control input end of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com