Power cable bender and method of use

A power cable and bender technology, applied in the field of power cable benders, can solve the problems of inconvenient carrying, inconvenient threading and safety hazards, etc., and achieve the effect of being convenient to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

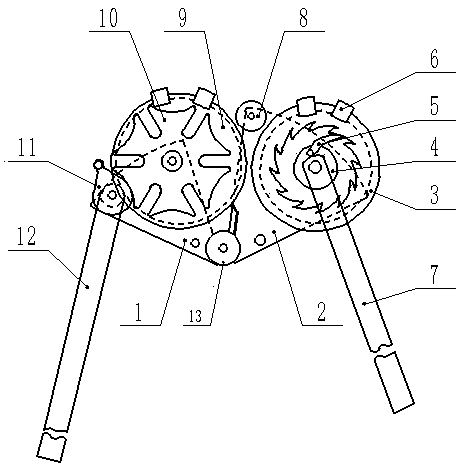

[0024] The invention is a power cable bender, as attached figure 1 As shown, a power cable bender includes a support plate A1, and the lower ends of the support plate A1 and the support plate B2 are overlapped and fixedly connected to each other, and an angle adjustment device 13 is arranged at the connection, and the angle adjustment device 13 may include an adjustment knob , the adjustment knob is stepped, the head of the adjustment knob is a grip part, the lower part of the grip part is connected with a cylinder concentric with the grip part, the cylinder is provided with a tooth part, and the tooth The lower end of the part is a rotating shaft, the rotating shaft of the adjustment knob is connected with the tooth part and the support plate A1, the tooth part of the adjustment knob is meshed with the tooth part at the lower end of the support plate B2, and on the support plate A1 A fixing bolt connected to the rotating shaft of the adjusting knob is provided, and after the ...

Embodiment 2

[0031]Embodiment 2 is the same as Embodiment 1, except that a support frame is added in Embodiment 2, which is used to reduce the burden of manpower when bending cables with a larger cross-sectional diameter, and external force can be used. The support plate A1 and the support plate B2 fix the power cable bender on the support frame through the fixed holes provided, and the upper side of the support frame is provided with a fixing device for the operating rod A12. When the support rod A rotates to a certain position, adjust After the angle is fixed, fix the support rod A. The support frame is provided with a position for placing the motor, and also has a connecting rod, one end of which can be connected with the motor, and the other end is connected with the operating rod B7 to drive the operating rod B7.

[0032] During specific operation, adjust the angle adjustment device to adjust the angle between the support plate A1 and the support plate B2 to an appropriate angle, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com